Quick Start Guide to Installing Inboard Motor

Installing Inboard Motor breathes life into your vessel, turning solid boats or life boats into powerhouses ready for magical destinations like deep water explorations. Inboard engines require precision—think engine beds, propeller shaft alignment, and a bit of patience. This guide equips boat owners with detailed steps, from using an engine crane to applying marine sealant, ensuring your engine installation project sails smoothly. Whether you’re upgrading a dinghy motor or powering larger boats, here’s how to harness aquatic might with confidence.

[BUTTON: Find Professional Inboard Motor Installation Services]

Explore Boat Engine Installation Repair for expert help.eparing the necessary tools and equipment to performing the final checks and testing.

- Best Outboard Prices: Navigating the Boat Motor Market

- Winterize Outboard Motor: Safeguarding Your Aquatic Ally

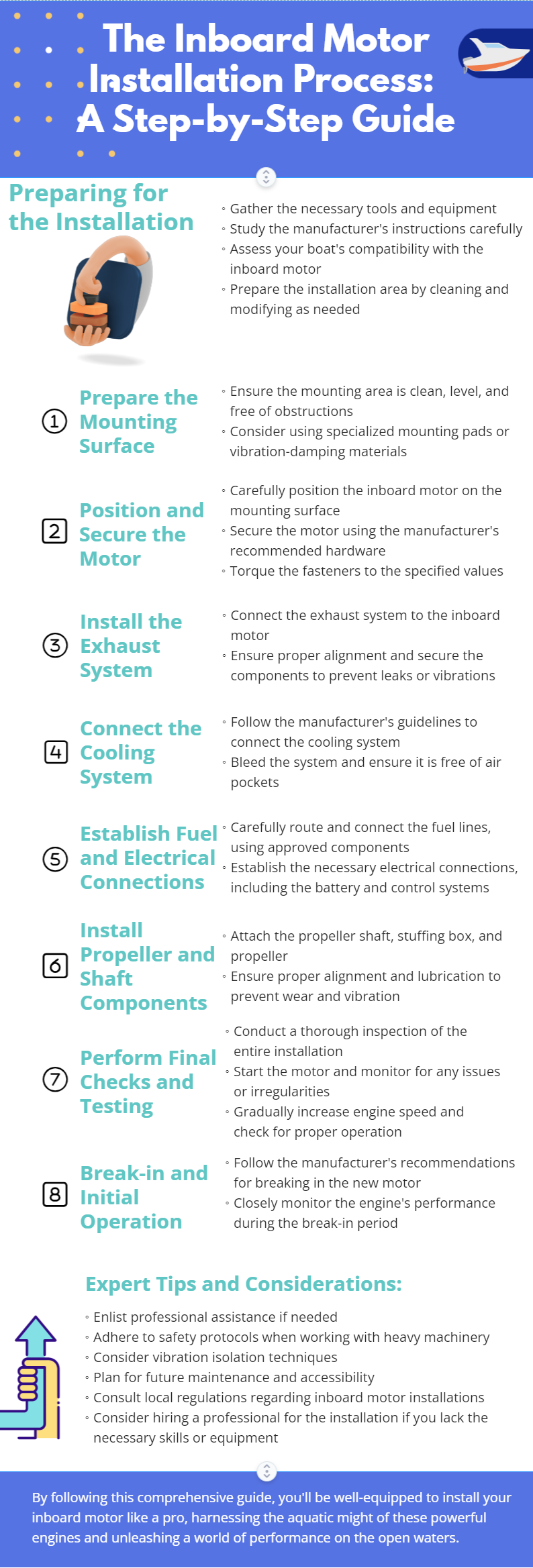

Preparing for Installing Inboard Motor

Essential Tools and Initial Setup

Before installing Inboard Motor, gather a robust toolkit: wrenches, sockets, pliers, an engine alignment tool, and a motor hoist—vital for larger boats with heavy engine types. Marine Enterprises suggest safety gear—gloves, goggles, and a 12v panel-ready electrical kit—to protect during this intricate process. Study engine drawings and the manufacturer’s manual, perhaps inspired by Jarett Bay’s meticulous approach in Beaufort NC. John Keats might liken this preparation to poetic precision, ensuring every step aligns with your boat’s design.

Assessing Boat Compatibility and Space

Verify your boat’s compatibility—boat designers stress hull strength for engine mount footprints and engine bearers. Check boat management tools to assess size, weight, and center of gravity against the engine footprint. For boats with engines or an auto engine conversion, engine modifications may be needed. Prep the engine compartment by clearing the engine box, ensuring engine feet align with motor bearers—considerable time here prevents future headaches.

Prepping the Installation Area

Drill an exploratory hole for the propeller shaft height, checking the diameter hole and aperture under sail to minimize drag under sail. Use marine sealant around the stuffing box and shaft bearing for a watertight seal—crucial for deep water or cold water inlet systems. This prep, though requiring loads of time, sets the stage for a boat under power that’s ready for adventure.

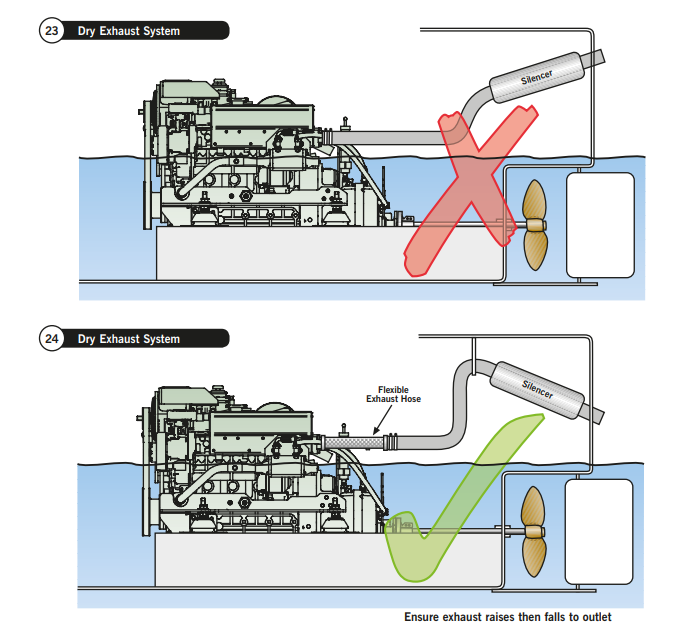

Step-by-Step Process for Installing Inboard Motor

Mounting the Inboard Engine

Installing Inboard Motor begins with securing engine beds—reinforce with BS1088 Marine plywood if needed for larger boats. Use an engine crane to position the modern engine, aligning engine mounts to motor bearers with a bit of patience. Torque bolts to spec, avoiding unusual noises from a misaligned crank shaft—Marine Enterprises note this precision extends engine longevity. Secure with motor mount pads to reduce vibration, a tip boat owners in Beaufort NC swear by.

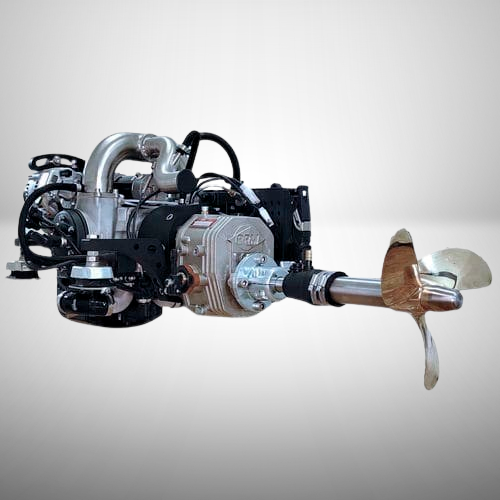

Connecting Propeller Shaft and Components

Attach the propeller shaft—diameter propeller shaft and shaft alignment are key—along with the stuffing box and stern rail. Far Reach Voyages’ Jarett Bay insights highlight a critical stuffing box to prevent leaks—seal with marine sealant for a solid boat. Install drive shaft systems and control in reverse mechanisms, ensuring control under power will satisfy an audience eager for magical destinations. A bronze rail original adds durability—check Boat Parts Accessories for quality components.

Fuel and Cooling Systems Setup

Route fuel lines from a gallon fuel tank—consider an aluminum diesel fuel tank for efficiency—to the engine intake. Board fuel tank placement affects balance, so plan fuel storage carefully. Connect the cold water inlet and diesel fuel tank, bleeding lines to avoid engine intake flush issues—delivery times for parts from Inboard Engine Maintenance can vary, so order early. This setup ensures decent money spent yields a reliable boat under power.

Electrical and Control Connections

Wire the engine instrument cluster and electrical panel—spend considerable time to prevent shorts. Link controls to the quarter berth, ensuring additional control surface functionality. A couple times testing connections avoids costly fixes—boat management demands precision here. Source wiring from Boat Systems Checklist to keep your vessel humming smoothly.g system is properly bled and free of air pockets, which can impede efficient cooling.

Testing and Breaking In Your Inboard Motor

Final Checks Before Launching

After installing Inboard Motor, inspect fuel lines, stern rail, and engine oil catch basin—listen for unusual noises during a test run. Start in shallow water, then deep water, using an engine alignment tool for shaft bearing precision—loads of time here ensures engine design beds in properly. Check the 12v panel and control under power will systems for a boat ready to explore.

Break-In Period and Initial Operation

Run the engine at varying speeds—modern engine break-in per manufacturer’s guide takes time but pays off. Monitor performance with boat management tools, ensuring boats with engines thrive without needing a cost of replacement engine later. A decent money investment now saves reasonable money on repairs—track via Boat Repair Florida.

Expert Tips for Installing Inboard Motor

Accessibility: Position the engine box for easy engine intake and maintenance—dinghy motor lessons apply here.

Enlist Pros: Unsure? Hire experts from Marine Engine Rebuilders Florida—better than risking an auto engine misfit.

Vibration Isolation: Use motor mount pads—engine bearers reduce stern rail stress.

Fuel Planning: Aluminum diesel fuel tank sizing impacts fuel storage—plan ahead.

Regulations: Check local boat management rules—save reasonable money on fines.

Conclusion

Installing Inboard Motor empowers boat owners to unlock larger boats’ potential, blending life boats’ reliability with exploratory hole precision from Jarett Bay and Beaufort NC wisdom. From engine beds to fuel lines, this guide—rich with engine modifications and boat designers’ insights—ensures your inboard motors roar for deep water voyages. With an engine crane, marine sealant, and support from Boat Maintenance Miami, your vessel’s aquatic might shines—saving decent money and time for magical destinations.

[BUTTON: Hire Inboard Motor Installation Experts]

Visit Boat Engine Diagnostics.