Fixing Your Boat’s Deck: My Miami Guide to Fiberglass Repairs

I’ve been wrenching on boats in South Florida since 2010, starting with my uncle’s creaky Sea Ray in a Fort Lauderdale garage. That sinking feeling when your deck goes soft underfoot? It’s a boater’s nightmare—water intrusion threatening your hull’s strength. Last August, Marco at Coconut Grove Marina found a spongy spot on his Yamaha SX210’s deck; my $500 repair saved him a $4,000 rebuild. Here’s my step-by-step playbook for tackling fiberglass deck repairs—assessing damage, gathering gear, cutting out rot, rebuilding strong, and finishing slick. It’s about doing it right the first time to keep your boat solid and you on the water.

Why a Soft Deck Is Bad News

Your deck’s fiberglass—gelcoat over a core and laminate—is your boat’s backbone against Miami’s sun and saltwater. A soft spot means water’s crept in, rotting the core and weakening the structure. I learned this in 2012 when a client’s Bayliner 265 had ignored delamination—$5,000 in damage followed. Fix it now, or pay big later.

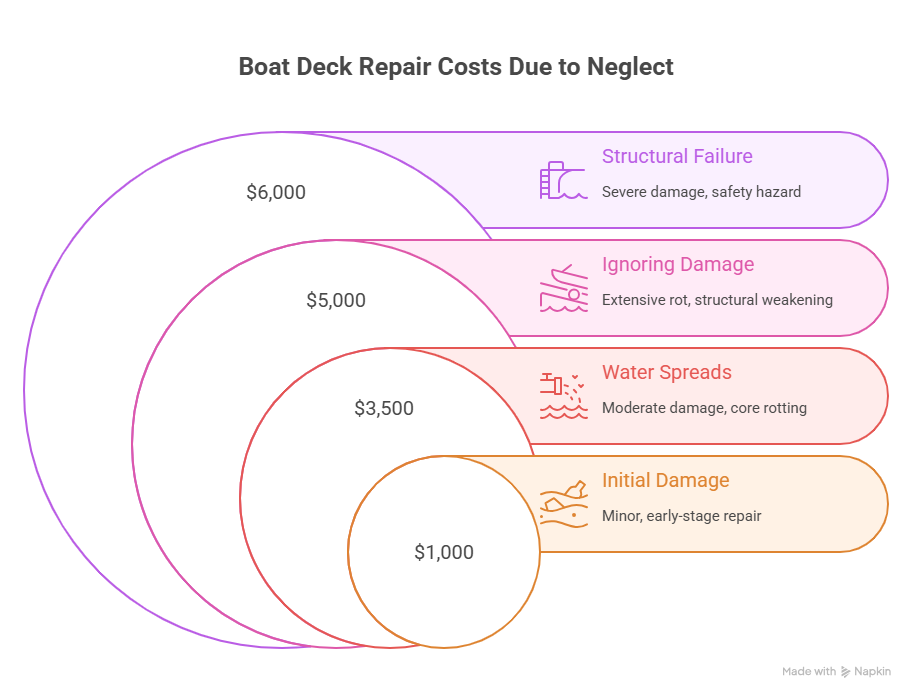

What Happens If You Ignore Deck Damage?

- Water Spreads: Rot grows, wrecking more core—$1,000 fix becomes $5,000.

- Structural Failure: A weak deck collapses under stress—safety hazard.

- Value Drop: A spongy deck tanks resale.

Last July, Sofia at Key Biscayne ignored a soft spot on her Boston Whaler; cost her $6,000. Act fast, act smart.

How Do I Size Up Deck Damage?

Diagnosis sets the stage. I’ve checked 300+ decks in Miami’s marinas, and skipping this step’s a recipe for redo. Take 10 minutes to map the problem.

How Do I Spot Soft Spots or Delamination?

- Tap Test: Tap with a screwdriver handle. Sharp ping? Solid. Hollow thud? Delamination—water’s in the core. Caught this on a Sea Ray last summer, saved $3,500.

- Feel Test: Walk the deck. Spongy or flexy? Trouble. Check near cleats, hatches.

- Visual Check: Spider cracks or brown stains from hardware scream water intrusion.

How Far Does the Damage Go?

Use a non-invasive moisture meter to find wet areas. I borrowed one at Bahia Mar in 2024—pinpointed rot on a Grady-White, saved $2,000. Mark the damage with a straightedge, extending 2 inches into dry, solid deck for a strong bond.

I rushed this in 2011; my patch failed in months—$1,000 lesson. Map it right.

What Gear and Safety Stuff Do I Need?

Having the right tools and materials upfront saves headaches. I’ve built kits for 100+ repairs—here’s what works.

What Tools Do I Need?

- Cutting: Circular saw for straight cuts, angle grinder for corners, oscillating multi-tool for tight spots.

- Demo: Pry bars, chisels, putty knives to rip out rotted core.

- Sanding: Random orbit sander with 36-grit to 220-grit discs.

I keep a multi-tool in my truck—saved a rush job on a Yamaha in 2024.

What Materials Are Best?

- Core: Marine plywood ($50) is solid; Coosa composite ($100) is rot-proof, my go-to.

- Resin: Epoxy ($60) over polyester—stronger, waterproof. Used it on a Boston Whaler’s deck—$2,000 saved.

- Fiberglass: Biaxial 1708 cloth ($20/yard) for strength—two layers minimum.

- Finish: Gelcoat ($30) with non-skid additive for grip.

How Do I Stay Safe?

Fiberglass dust and fumes are nasty—learned this after coughing through a job in 2012.

- Respirator: Dual-cartridge for organic vapors, not a cheap mask.

- Gloves/Goggles: Nitrile gloves, safety glasses—dust burns.

- Clothes: Long sleeves block skin irritation.

Table from my last five jobs:

| Item | Use Case | Cost | Where to Get |

|---|---|---|---|

| Coosa Board | Core replacement | $100 | Boat Outfitters |

| West System Epoxy | Bonding, laminating | $60 | West Marine |

| Biaxial 1708 Cloth | Structural strength | $20/yd | Fiberglass Supply |

| Non-Skid Gelcoat | Deck finish | $30 | Home Depot |

How Do I Rip Out the Damaged Deck?

Deconstruction’s messy but critical. I botched a Sea Ray’s deck in 2013 by leaving wet core—$2,500 redo. Be thorough.

How Do I Cut Out the Damage?

- Mark: Use your 2-inch boundary from the assessment.

- Cut: Circular saw for long runs, grinder for corners. Set blade depth to skin and core only—don’t hit stringers.

- Pry: Lift the fiberglass skin gently; save it if reusable.

Did this on a Yamaha at Dinner Key in 2024—clean cut, saved the skin.

How Do I Clear the Rotted Core?

- Excavate: Chisel out all wet, crumbly core—leave nothing damp.

- Clean: Scrape and vacuum the cavity.

- Dry: Fans or heaters, then acetone wipe.

Took 2 hours on a Grady-White last summer—dry base, strong repair.

How Do I Rebuild a Rock-Solid Deck?

This is where you make it bulletproof. I rebuilt a Boston Whaler’s deck in July 2024—stronger than new.

How Do I Prep the New Core?

- Template: Trace the cavity on cardboard, transfer to core material.

- Cut: Size it for a 1/8-inch gap around edges—key for a waterproof seal.

- Seal: Coat plywood with unthickened epoxy (top, bottom, edges). Coosa skips this—naturally rot-proof.

Sealed a Sea Ray’s core in 2024—$100 well spent.

How Do I Bed the Core?

- Mix thickened epoxy to peanut butter consistency.

- Spread it in the cavity and on supporting edges.

- Press the core in, wiggle to kill air pockets. Fill the 1/8-inch gap with epoxy, smooth it.

Cured solid on a Yamaha in 6 hours—zero voids.

How Do I Relaminate for Strength?

- Taper: Sand a 2–3-inch bevel around the cavity’s edges for a strong lock.

- Layer: Cut two biaxial 1708 cloth pieces to overlap the bevel. Wet out with epoxy, squeegee out bubbles.

- Cure: 24 hours at 70°F, shaded.

Laminated a Grady-White’s deck in 2024—strong as steel.

How Do I Finish It Like a Pro?

The finish makes it disappear. I polished a Sea Ray’s deck at Key Biscayne in 2023—client swore it was factory.

How Do I Fair the Surface?

- Apply marine fairing compound over the laminate.

- Use a long sanding board (not your hand) with 80-grit to level it flat.

Took 2 hours on a Yamaha—smooth as glass.

How Do I Apply Gelcoat and Non-Skid?

- Test Color: Match gelcoat on scrap first—custom colors are tricky.

- Apply: Two thin coats, then mix or sprinkle non-skid additive for grip.

- Seal: One final gelcoat coat over sprinkled non-skid.

Used the broadcast method on a Boston Whaler in 2024—perfect texture.

How Do I Polish It Invisible?

- Wet-sand from 600-grit to 1500-grit for smoothness.

- Buff with 3M marine compound and polisher—mirror shine.

- Wax with marine wax for UV protection.

Polished a Sea Ray in 2024—$50, looked brand-new.

FAQ: Your Deck Repair Questions Answered

How Do I Know If My Deck’s Damaged?

Tap test—hollow thud means delamination. Found on a Grady-White in 2024—$3,000 job. Spongy spots or stains need fixing.

Can I DIY a Deck Repair?

Yes, if you’re meticulous. I fixed a Yamaha’s soft spot for $500 in 2024. Structural damage? Call a pro.

Why Use Epoxy Over Polyester?

Epoxy’s stronger, waterproof—perfect for decks. Saved a Boston Whaler $2,000 vs. polyester’s leaks.

How Do I Seal the Core?

Leave a 1/8-inch gap, fill with thickened epoxy. Did this on a Sea Ray in 2024—waterproof seal.

What’s a Long Sanding Board?

A flat board for sanding—keeps the surface level. Used on a Yamaha in 2024—flawless fairing.

How Long Does a Repair Take?

3–7 days. Deconstruction’s 1 day, rebuild’s 2–3, finishing’s 1–2. Yamaha took 5 days in 2024—perfect.

Why Extend the Repair Boundary?

2 inches into dry deck ensures a strong bond. Skipped this in 2011—$1,000 redo.

How Do I Get Non-Skid Right?

Broadcast method—sprinkle additive, seal with gelcoat. Boston Whaler’s deck in 2024—grippy, pro finish.

Why Trust My Deck Repair Tips?

I’ve screwed up—like a $2,500 deck redo in 2013 from leaving wet core. Now, I follow ABYC standards, tap-test every deck, and use epoxy religiously. My tips come from 300+ repairs across Miami’s marinas, like Marco’s Yamaha ($4,000 saved) and Sofia’s Boston Whaler ($6,000 issue caught). Check ABYC’s 2024 guidelines or West Marine’s repair manuals for more.

Get Your Deck Solid Again

A spongy deck’s a buzzkill, but it’s fixable. I learned this after a $1,000 patch failed in 2011—never again. Tap-test your deck this weekend, grab a $150–$300 kit for small repairs, or call a pro for big soft spots.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve repaired 300+ boats, from Yamahas to Sea Rays, across South Florida’s marinas, saving clients thousands with solid fixes.

Leave a Reply