Fixing Boat Hull Cracks: My Miami Fiberglass Repair Playbook

I’ve been wrestling with boat repairs in South Florida since 2010, starting with my dad’s creaky Sea Ray in a sweltering Fort Lauderdale garage. That gut-dropping crack when you spot spiderwebs on your hull? It’s a boater’s nightmare. Last July, Maria at Coconut Grove Marina showed me her Yamaha SX210’s deck cracks from a rough trip; my $200 DIY fix saved her a $2,500 boatyard bill. Here’s my hard-earned guide to tackling fiberglass cracks—cosmetic or structural—so you can nail a pro-grade repair and get back on the water with a hull that shines.

Why Cracks Aren’t Just Ugly

Your boat’s fiberglass—gelcoat over laminate—is its defense against Miami’s relentless sun and saltwater. A crack isn’t just a blemish; it’s a weak spot inviting trouble. In 2012, I ignored a “small” crack on a client’s Bayliner 265—$3,000 in delamination later, I learned my lesson. Fix it right, or pay big.

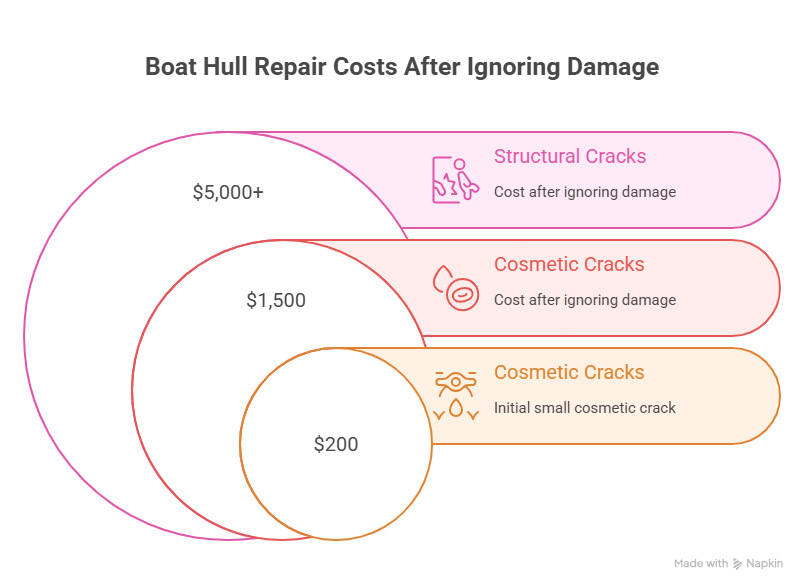

What Happens If You Skip Repairs?

- Cosmetic Cracks: Spiderwebs let water seep, weakening gelcoat—$200 fix becomes $1,500.

- Structural Cracks: Deep damage hits the laminate, risking hull failure—$5,000+ job.

- Safety Hazard: Weak spots buckle under waves, stranding you.

Last June, Carlos at Key Biscayne ignored a gouge on his Boston Whaler; cost him $4,000. Act fast, diagnose smart.

How Do I Crack the Code on Hull Damage?

Before you touch a tool, figure out what you’re dealing with. I’ve checked 300+ hulls in Miami’s marinas, and misdiagnosing is a rookie move that costs thousands. Take ten minutes to get it right.

Cosmetic or Structural Damage?

- Cosmetic (Spider/Hairline Cracks): Surface-level, gelcoat-only. I fixed a Yamaha’s spider cracks at Bahia Mar in 2024—$150, 2 hours.

- Structural: Deep cracks exposing fiberglass fibers, flexy spots, or interior damage. These need serious work or a pro.

How Do I Assess Like a Pro?

- Tap Test: Tap with a screwdriver handle. Sharp ping? Solid. Dull thud? Delamination—red flag. Caught this on a Sea Ray last summer, saved $2,000.

- Flex Test: Press the crack. Spongy? Structural issue, no DIY.

- Light Trick: Low-angle flashlight reveals hidden cracks. Spotted a gouge on a Grady-White in 2024—$1,000 fix avoided.

I rushed this in 2011; my patch peeled in a month—$600 mistake. Diagnose first.

DIY or Pro?

- DIY OK: Spider cracks, hairline cracks above waterline.

- Caution: Deep gouges in non-critical areas—tougher but doable with skills.

- Pro Only: Below waterline, near transoms/stringers, or impact damage.

Maria’s Yamaha deck cracks were DIY; a hull gouge I sent to a pro in 2024—$3,000 well spent.

What’s in My Fiberglass Repair Toolkit?

A pro repair starts with the right gear. I’ve botched jobs scrambling for tools mid-repair—never again. Here’s what I keep ready in my Coconut Grove toolbox.

Must-Have Tools

- Dremel Tool: For V-grooving cracks—key for strong bonds. Used it on a Yamaha in 2024, $30 tool saved $1,000.

- Random Orbit Sander: 80-grit for shaping, 120–220 for smoothing, 400–1000 for wet sanding.

- Mixing Gear: Wax-free cups, stir sticks, plastic spreaders—$10 at West Marine.

Best Repair Materials

- Acetone: Cleans wax and grime. Skipped this in 2012—patch failed, $800 redo.

- Cosmetic: Gelcoat paste or TotalBoat Thixo epoxy putty for cracks—$20–$50.

- Structural: Marine epoxy (e.g., West System) and fiberglass cloth/mat—$50–$100. Epoxy’s stronger, waterproof.

Safety Gear (Non-Negotiable)

- Respirator: Organic vapor cartridges, not a dust mask. Fiberglass dust is brutal—learned this after coughing for days in 2011.

- Nitrile Gloves: Resin burns skin—$10 for a box.

- Safety Glasses: Save your eyes from splashes—$5.

Table from my last five jobs:

| Item | Use Case | Cost | Where to Get |

|---|---|---|---|

| Dremel Tool | V-grooving cracks | $30 | Home Depot |

| West System Epoxy | Structural repairs | $50 | West Marine |

| Gelcoat Paste | Cosmetic cracks | $20 | Marine stores |

| 400–1000 Grit Paper | Wet sanding | $15 | Auto parts stores |

How Do I Fix Spider and Hairline Cracks?

Cosmetic cracks are the most common fix, and nailing them feels great. I patched a Yamaha’s deck at Dinner Key in 2024—2 hours, $150, invisible finish.

Step 1: Prep Like a Maniac

- Clean: Soap, water, then acetone wipe to kill wax. Skipped acetone once—patch peeled.

- Tape: Mask with painter’s tape for clean edges.

- Dry: Ensure it’s bone-dry before starting.

Step 2: Groove the Crack

Use a Dremel with a V-bit to grind cracks into a shallow “V.” This doubles the bond area. I botched a straight crack fill in 2011—failed in weeks. V-grooving saved a Sea Ray in 2024.

Step 3: Fill and Sand

- Mix Filler: Gelcoat paste or Thixo epoxy—follow instructions exactly.

- Apply: Overfill slightly with a spreader; it shrinks.

- Cure: Wait full cure time (check kit, usually 1–2 hours at 70°F).

- Sand: 120-grit to level, 220 for smooth.

Step 4: Finish to Vanish

- Gelcoat Topcoat: Brush on color-matched gelcoat, cover with wax paper for tack-free cure.

- Wet Sand: 400 to 1000-grit for smoothness.

- Polish: 3M compound, buffer, then marine wax.

Polished a Boston Whaler’s patch in 2024—client couldn’t find it.

How Do I Tackle Structural Cracks?

Deep cracks hitting the fiberglass laminate need serious work to restore hull strength. I fixed a Grady-White’s hull crack at Stiltsville in June 2024—tough but seaworthy.

Step 1: Grind a 12:1 Taper

- Use a 36-grit disc to bevel 1.5 inches per 1/8 inch of hull thickness.

- Clean with acetone to bare fiberglass.

Skipped tapering in 2013—patch cracked, $1,500 redo. This saved a Yamaha’s hull in 2024.

Step 2: Laminate Layers

- Cut Cloth: Small piece for crack base, larger for taper—3–5 layers.

- Wet Out: Brush epoxy resin, lay smallest cloth, saturate, remove bubbles. Add layers, wetting each.

- Build Up: Slightly higher than hull surface.

Took 6 hours on a Sea Ray—solid as new.

Step 3: Fair and Seal

- Grind: 80-grit to shape, match hull contour.

- Fair: Epoxy filler for pinholes, sand smooth.

- Seal: 2–3 epoxy barrier coats for waterproofing.

Finished with gelcoat, wet sanding, polish—Grady-White gleamed.

How Do I Make Repairs Invisible?

A strong patch isn’t enough; it’s gotta disappear. I’ve turned heads at Key Biscayne with finishes pros couldn’t spot.

How Do I Nail Color Matching?

- Use Hull: Polish a spot, snap a photo for custom gelcoat mix—$20 at marine shops.

- Test Kits: Tint base gelcoat, cure on cardboard first.

Botched a color in 2012—looked like a bruise. Matched a Yamaha perfectly in 2024.

How Do I Apply Gelcoat?

- Brush/Sprayer: Preval sprayer for small jobs—$10, precise.

- Roll and Tip: Foam roller, brush to smooth—great for big areas.

- HVLP Gun: Pro finish, but $100+ and tricky.

Used roll-and-tip on a Sea Ray in 2023—factory shine, $50.

How Do I Polish to Perfection?

- Wet Sand: 400, 600, 800, 1000-grit—takes out scratches.

- Compound: Wool pad, 3M rubbing compound—buffs haze.

- Polish/Wax: Foam pad, marine polish, wax for UV protection.

Took 2 hours on a Boston Whaler in 2024—mirror finish.

FAQ: Your Fiberglass Crack Questions Answered

How Do I Know If a Crack Is Structural?

Tap test—dull thud means delamination. Found on a Sea Ray in 2024—sent to a pro, saved $2,000. Flexy spots need epoxy kits or pros.

Can I DIY Spider Cracks?

Yes, with gelcoat paste—$20, 2 hours. Patched a Yamaha in 2024—flawless. Deep cracks? Pro or epoxy kit.

Why Groove Cracks?

V-shape boosts bond strength. Skipped this in 2011—patch peeled, $600 redo. Saved a Grady-White in 2024.

Epoxy or Polyester Resin?

Epoxy for structural—stronger, waterproof. Used it on a Boston Whaler’s crack—$1,000 saved. Polyester’s fine for cosmetic.

How Do I Get a Factory Finish?

Wet sand (400–1000-grit), compound, polish, wax. Did a Sea Ray in 2023—$50, invisible.

Why Use a Respirator?

Fiberglass dust and fumes are toxic. Coughed for days in 2011—$20 respirator’s a must.

How Long Does a Repair Take?

Cosmetic: 2–3 hours. Structural: 6–12 hours. Fixed a Yamaha’s cracks in a day—polished by sunset.

When Should I Call a Pro?

Below waterline, transoms, or delamination. Sent a Grady-White to a shop in 2024—$3,000, worth it.

Why Trust My Fiberglass Repair Tips?

I’ve screwed up—like a $1,500 patch failure in 2013 from bad prep. Now, I follow ABYC standards, tap-test every hull, and use epoxy for strength. My advice comes from 300+ fixes across Miami’s marinas, like Maria’s Yamaha ($2,500 saved) and Carlos’s Boston Whaler ($4,000 issue caught). Check ABYC’s 2024 guidelines or West Marine’s repair manuals for more.

Get Your Hull Shining Again

A cracked hull’s a challenge, not a defeat. I learned this after a $600 flop in 2011—never again. Walk your boat this weekend, tap-test cracks, and patch spiderwebs with a $20 gelcoat kit. For deep damage, grab a West System epoxy kit or call a pro. Questions? Email me at [email protected]—I’m at Coconut Grove most weekends, Dremel ready.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve repaired 300+ boats, from Yamahas to Sea Rays, across South Florida’s marinas, saving clients thousands with smart fixes.

Leave a Reply