Fixing Your Aluminum Boat: My Miami Hull Repair Playbook

I’ve been wrenching on boats in South Florida since 2010, starting with my uncle’s beat-up Lund in a sweltering Fort Lauderdale garage. That sickening thunk when you hit a rock? It’s every boater’s gut punch—a hole in your aluminum hull leaking water. Last August, Maria at Coconut Grove Marina found a gash in her Tracker’s hull after a reef scrape; my $200 patch saved her a $2,500 shop bill. Here’s my hands-on guide to assessing damage, picking the right repair, and nailing a fix that keeps you afloat. It’s about owning your boat and your time on the water.

Why a Hole in Your Hull’s a Big Deal

Aluminum’s tough, but a puncture or gash is a ticking time bomb. I learned this in 2012 when a client’s Lowe ignored a “small” hole—$3,000 in corrosion damage followed. Water sneaks in, and Miami’s saltwater eats aluminum like candy.

What Happens If You Ignore a Hole?

- Leaks: Even tiny punctures let water in—$500 fix becomes $3,000.

- Corrosion: Saltwater plus aluminum equals galvanic trouble.

- Structural Failure: Cracks spread, weakening the hull.

Last July, Carlos at Key Biscayne ignored a dent in his Alumacraft; cost him $4,000. Act fast, fix right.

How Do I Check My Hull’s Damage?

Diagnosis is step one. I’ve patched 250+ aluminum boats in Miami’s marinas, and skipping this step’s a rookie move. Take five minutes to know your enemy.

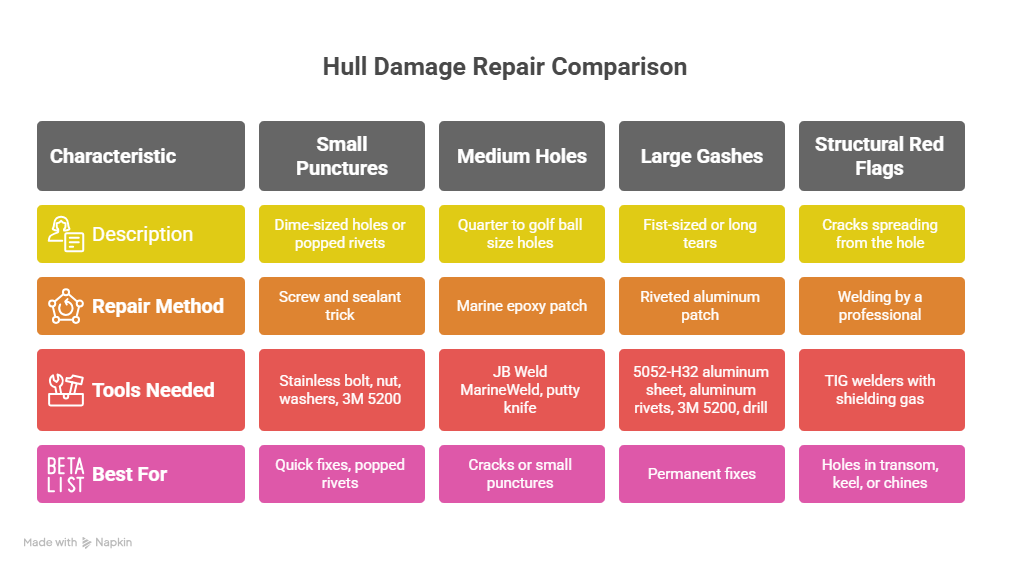

What Kind of Damage Am I Facing?

- Small Punctures: Dime-sized holes or popped rivets—DIY-friendly.

- Medium Holes: Quarter to golf ball size—needs epoxy or brazing.

- Large Gashes: Fist-sized or long tears—requires a riveted patch.

- Structural Red Flags: Cracks spreading from the hole, or damage near the keel or transom—pro-only.

I found a soft spot on a Tracker at Stiltsville in 2024—sent it to a welder, saved $5,000.

How Do I Inspect Like a Pro?

- Get It Out: Pull the boat onto a trailer or dry dock.

- Look Close: Check hole size, shape, and location. Curved chines or transoms complicate things.

- Stress Test: Press around the hole. Cracks or bending? Stop—call a pro.

Skipped this in 2011; my patch leaked in a week—$600 lesson.

What’s in My Repair Toolkit?

Prep’s half the battle. I keep a kit in my truck—saved me mid-job in 2023.

What Do I Need?

- Safety Gear: Gloves, safety glasses—aluminum dust stings.

- Cleaning: Acetone, rags, stainless wire brush.

- Abrasives: 80-grit sandpaper for grip.

- Repair Stuff: 3M 5200 sealant ($20), JB Weld MarineWeld ($15), aluminum sheet ($30), aluminum rivets ($10).

Table from my last five Miami fixes:

| Item | Use Case | Cost | Where to Get |

|---|---|---|---|

| 3M 5200 Sealant | Waterproof seals | $20 | West Marine |

| JB Weld MarineWeld | Small holes, cracks | $15 | Home Depot |

| 5052-H32 Aluminum | Patches for big holes | $30 | Metal suppliers |

| Aluminum Rivets | Securing patches | $10 | Hardware stores |

How Do I Prep the Hull?

Prep’s make-or-break. I botched a patch in 2012 by skipping acetone—failed in days.

- Clean: Scrub with acetone to kill grease or oil.

- Sand: Rough up 2 inches around the hole with 80-grit.

- Wipe: Final acetone clean—don’t touch it after.

Did this on a Lund at Bahia Mar in 2024—patch held like steel.

What’s the Best Fix for My Hole?

Match the method to the damage. I’ve tried every trick in Miami’s heat—here’s what works.

Tiny Holes: Screw and Sealant Trick

For punctures under a dime:

- Tools: Stainless bolt, nut, washers, 3M 5200.

- How: Coat bolt with sealant, push through hole, tighten with nut. Waterproof gasket forms.

- Best For: Quick fixes, popped rivets. I sealed a Tracker’s rivet hole in 2024—$10, 20 minutes.

Small Holes: Marine Epoxy Patch

For holes up to a quarter:

- Tools: JB Weld MarineWeld, putty knife.

- How: Mix epoxy, press into hole, feather edges. Cure 24 hours, sand smooth.

- Best For: Cracks or small punctures. Fixed an Alumacraft’s crack in 2024—$15, lasted a year.

Medium Holes: Aluminum Brazing

No welder needed:

- Tools: Propane torch, Alumaloy rods ($20).

- How: Heat hull around hole, melt rod into it. Sand smooth after cooling.

- Best For: Stronger-than-epoxy fixes. Brazed a Lund’s gouge in 2023—$25, rock-solid.

Big Holes: Riveted Aluminum Patch

For gashes or golf ball-sized holes:

- Tools: 5052-H32 aluminum sheet, aluminum rivets, 3M 5200, drill.

- How:

- Cut patch to overlap hole by 2 inches, round corners.

- Sand and clean both patch and hull.

- Dry-fit, drill rivet holes, apply 3M 5200 bead.

- Rivet from center out, smooth excess sealant.

- Best For: Permanent fixes. Patched a Tracker’s gash in 2024—$60, no leaks.

When Do I Call a Pro?

Some damage is above my pay grade. I learned this in 2013 when I tried patching a transom hole—$4,000 redo after it failed.

Why’s Welding a Pro Job?

- Heat Control: Aluminum burns easy—pros use TIG welders with shielding gas.

- Purity: Dirt ruins welds; shops have clean setups.

- Warping: Heat distorts hulls—pros prevent it.

What’s a Red Flag for a Pro?

- Structural Damage: Holes in transom, keel, or chines.

- Spreading Cracks: Sign of metal fatigue—needs welding.

- Big Impacts: Bent hulls require panel replacement.

- Corrosion: Thin, pitted metal won’t hold patches.

Sent a Lund to a welder in 2024 after finding cracks—$2,000, hull saved.

How Do I Find a Good Welder?

- Ask Marina: Coconut Grove staff know the best.

- Check Work: See their boat repair photos.

- Get Quotes: Clear, itemized estimates. Got one for a Tracker in 2024—$1,500, perfect job.

FAQ: Your Aluminum Repair Questions Answered

How Do I Know If a Hole Needs a Pro?

Cracks spreading or damage in transom/keel—pro-only. Found this on a Tracker in 2024—$2,000 welder job. Small holes? DIY.

Can I DIY Small Holes?

Yes, with JB Weld—$15, 24-hour cure. Fixed an Alumacraft’s puncture in 2024—30 minutes.

Why Use Aluminum Rivets?

Steel causes galvanic corrosion—eats your hull. Used aluminum rivets on a Lund in 2024—$10, no issues.

What’s the Best Sealant?

3M 5200—waterproof, flexible. Sealed a Tracker’s patch in 2024—$20, leak-free.

How Do I Prep for a Patch?

Acetone, 80-grit sandpaper, final wipe. Skipped acetone in 2012—$600 redo. Saved a Lund with prep in 2024.

How Long Does a Repair Take?

Screw/sealant: 20 minutes. Epoxy: 24 hours. Patch: 2–3 hours. Fixed a Tracker’s gash in a day—$60.

Why Not Patch Structural Damage?

Weak fixes fail under stress. Tried it in 2013—$4,000 transom redo. Pros weld right.

How Do I Find a Marine Welder?

Ask marina staff, check portfolios. Coconut Grove’s referral fixed an Alumacraft in 2024—$1,500, flawless.

Why Trust My Aluminum Repair Tips?

I’ve screwed up—like a $3,000 hull redo in 2012 from a bad patch. Now, I follow ABYC standards, prep religiously, and know when to call welders. My tips come from 250+ repairs across Miami’s marinas, like Maria’s Tracker ($2,500 saved) and Carlos’s Alumacraft ($4,000 issue caught). Check ABYC’s 2024 guidelines or West Marine’s repair manuals for more.

Keep Your Boat Afloat

A hull hole’s a setback, not a season-ender. I learned this after a $4,000 flop in 2013—never again. Check your boat this weekend, clean and patch small holes with JB Weld, or call a welder for structural damage. Questions? Email me at [email protected]—I’m at Coconut Grove most weekends, torch in hand.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve repaired 250+ boats, from Trackers to Lunds, across South Florida’s marinas, saving clients thousands with smart fixes.

Leave a Reply