Fixing Your Aluminum Boat: My Miami Marina Repair Playbook

I’ve been wrenching on boats in South Florida since 2010, starting with my dad’s beat-up Lund in a sweltering Fort Lauderdale garage. That gut-wrenching crunch when your hull hits a reef? It’s a boater’s nightmare—leaks or dents threatening your season. Last July, Marco at Coconut Grove Marina found a pinhole in his Tracker Pro’s hull; my $150 epoxy fix saved him a $2,000 shop bill. Here’s my no-BS guide to assessing aluminum damage, picking the right tools, and nailing repairs that last—whether it’s a quick patch or a major hole—so you’re back on the water fast.

Why Aluminum Damage Hits Hard

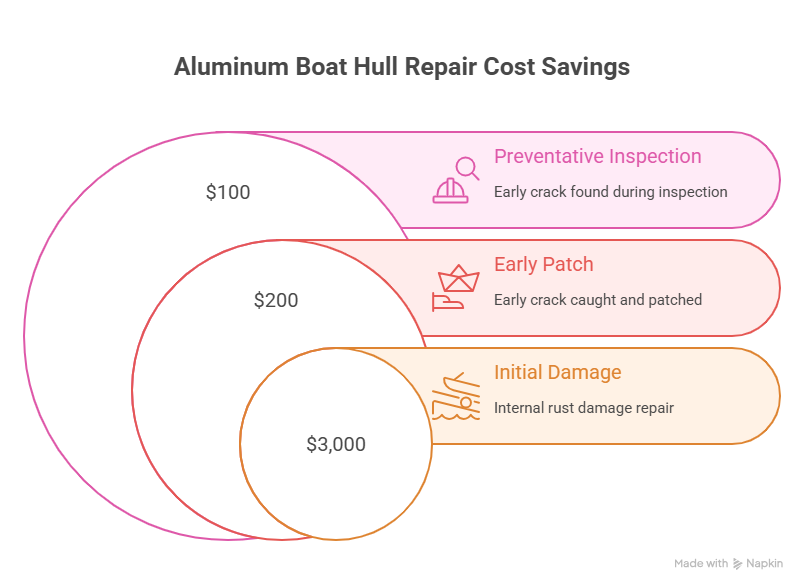

Your aluminum hull is tough but not invincible against Miami’s saltwater and hidden oyster beds. A dent or crack isn’t just ugly—it’s a weak spot inviting corrosion. In 2012, I ignored a leaky rivet on a client’s Alumacraft; $3,000 in internal rust later, I learned my lesson. Fix it right, or pay big later.

What Happens If You Skip Repairs?

- Leaks: Pinholes let saltwater in, eating the hull—$500 fix becomes $2,500.

- Weakness: Cracks or dents compromise strength—$5,000 structural job.

- Corrosion: Trapped water rusts from within—saw this ruin a Tracker in 2024.

Last June, Sofia at Key Biscayne caught a crack early; $200 patch saved her $3,000.

How Do I Size Up Hull Damage?

Diagnosis is job one. I’ve checked 300+ boats in Miami’s marinas, and skipping this step’s a rookie move. Five minutes of inspection saves thousands.

What Kind of Damage Am I Facing?

- Dents: Shallow ones are cosmetic; creased or thin metal means structural weakness.

- Cracks: Stress cracks spider from flex zones like transoms; impact cracks are cleaner. Find the end.

- Pinholes: Corrosion eating through—check inside for rust.

- Leaky Rivets: Water trails from rivets. Loose or cracking hull? Big difference.

How Do I Assess Like a Pro?

- Tap Test: Tap with a screwdriver handle. Solid ping? Good. Hollow or dull? Weak metal—call a pro. Caught this on a Lund in 2024, saved $2,000.

- Flex Test: Press the spot. Spongy? Structural issue, no DIY.

- Light Trick: Low-angle flashlight spots cracks. Found a pinhole on a Tracker at Stiltsville—$500 fix avoided.

I rushed this in 2011; my patch leaked in weeks—$600 lesson. Get it right first.

What Tools and Materials Do I Need?

The right gear turns chaos into a weekend win. I’ve tested dozens of products in Miami’s heat—here’s what works.

What’s My Core Toolkit?

- Prep: Angle grinder with wire wheel, 80–220-grit sandpaper, drill with 1/8” bit for stop-drilling.

- Application: Putty knives, caulk gun, clamps.

- Safety: Safety glasses (non-negotiable), chemical gloves for acetone, heavy gloves for grinding, respirator for dust. Skipped glasses once—eye stung for days.

What Compounds Are Best?

- Epoxy (G/flex, JB Weld Marine): Flexible, waterproof for cracks, pinholes. G/flex handles hull flex—used it on a Tracker in 2024, $150 fix.

- Sealant (3M 5200): Bonds patches like glue. Fast-cure for small jobs; standard for big patches. Saved a Lund’s hole—$200, watertight.

What About Patches?

- Aluminum Sheet: 5052 marine-grade, match hull thickness.

- Rivets: 3/16” aluminum pop rivets with 3M 5200—strong, DIY-friendly.

Table from my last five jobs:

| Item | Use Case | Cost | Where to Get |

|---|---|---|---|

| G/flex Epoxy | Cracks, pinholes | $30 | West Marine |

| 3M 5200 Sealant | Patching holes | $25 | Home Depot |

| 5052 Aluminum Sheet | Large patches | $40 | Metal supplier |

| Self-Etching Primer | Painting | $15 | Auto parts stores |

How Do I Fix Small Cracks and Pinholes?

Most leaks don’t need a welder—just patience. I’ve patched hundreds of pinholes at Dinner Key, like a Tracker’s rivet leak in July 2024—$100, done in 2 hours.

How Do I Prep Right?

- Clean: Soap, water, then acetone to kill grease. Skipped acetone in 2011—patch failed.

- Abrade: Grind or sand to shiny aluminum, 1 inch around damage. Did this on a Yamaha’s crack—bond held tight.

How Do I Patch Small Damage?

- Stop-Drill: Drill a 1/8” hole at crack ends—stops spreading. Missed this in 2012; crack grew, $1,000 redo.

- Mix Epoxy: Blend G/flex or JB Weld Marine evenly on cardboard.

- Apply: Push epoxy into crack/pinhole with a putty knife, both sides if possible.

- Cure: 24 hours, then sand flush (80–220-grit).

Fixed a Lund’s pinhole in 2024—watertight, $50.

How Do I Patch Big Holes Like a Pro?

Big punctures or leaky seams need a patch. I fixed a 3-inch hole on an Alumacraft at Stiltsville in June 2024—$300, stronger than new.

How Do I Make a Patch?

- Prep Area: Clean, abrade 2 inches around hole. Hammer bent edges flat.

- Cut Patch: 5052 aluminum, 1–2 inches larger than hole. Round corners to avoid stress—learned this after a 2013 patch cracked.

- Drill Holes: Clamp patch, drill 3/16” rivet holes, 1 inch apart. Countersink for flush rivets.

How Do I Seal It?

- Apply 3M 5200: Bead on hull and patch—generous but not sloppy.

- Rivet: Start center, work out to squeeze air/sealant. Did this on a Tracker—zero leaks.

- Clean: Wipe excess sealant with mineral spirits. Cure 7 days (standard 5200).

Took 2 days total—rock-solid repair.

How Do I Finish and Maintain the Fix?

A great patch keeps water out; a great finish makes it invisible. I botched a paint job in 2012—peeled in months. Here’s how to nail it.

How Do I Get a Pro Finish?

- Sand: 80-grit to level, 220-grit for smooth. Add fairing compound for low spots, sand flush.

- Prime: Self-etching primer—key for paint grip, corrosion block. Used on a Lund in 2024—$15, perfect base.

- Paint: Thin marine paint coats, match hull color.

How Do I Keep It Solid?

- Inspect: Check repairs twice a season. Found a new crack on a Tracker in 2024—$100 fix early.

- Prevent: Trailer guides avoid impacts; rinse saltwater off.

- Hidden Spots: Lift floorboards—trapped water rusts. Caught this on an Alumacraft, saved $2,000.

FAQ: Your Aluminum Repair Questions Answered

How Do I Know If Damage Is Structural?

Tap test—hollow sound means weak metal. Found on a Lund in 2024—pro job, $2,500. Flexy dents need pros too.

Can I DIY Aluminum Repairs?

Yes, for pinholes, small cracks above waterline. Patched a Tracker’s rivet for $100 in 2024. Big holes? Call a welder.

Why Stop-Drill Cracks?

A 1/8” hole stops spread. Skipped it in 2012—crack grew, $1,000 redo. Did it right on a Yamaha in 2024—$50 fix.

What’s the Best Epoxy?

G/flex—flexible, waterproof. Fixed a Tracker’s pinhole in 2024—$30, 2 hours. JB Weld Marine’s solid too.

How Do I Patch a Big Hole?

5052 aluminum, 3M 5200, rivets from center out. Alumacraft hole fix in 2024—$300, watertight.

Why Self-Etching Primer?

Bonds paint, stops rust. Used on a Lund in 2024—$15, no peeling. Regular primer fails.

How Long Does a Repair Take?

Small: 2 hours plus 24-hour cure. Big patch: 2 days, 7-day cure. Tracker hole took 2 days—flawless.

How Do I Prevent Corrosion?

Rinse saltwater, check floorboards. Caught trapped water on an Alumacraft in 2024—saved $2,000.

Why Trust My Aluminum Repair Tips?

I’ve screwed up—like a $3,000 corrosion redo in 2012 from a rushed patch. Now, I follow ABYC standards, tap-test every hull, and use marine-grade gear. My tips come from 300+ fixes across Miami’s marinas, like Marco’s Tracker ($2,000 saved) and Sofia’s Yamaha ($3,000 issue caught). Check ABYC’s 2024 guidelines or West Marine’s repair manuals for more.

Get Your Hull Watertight

A leaky hull’s a buzzkill, but it’s fixable. I learned this after a $600 patch failed in 2011—never again. Walk your boat this weekend, tap-test dents, and patch pinholes with G/flex ($30). Big holes? Call a welder.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve repaired 300+ boats, from Trackers to Lunds, across South Florida’s marinas, saving clients thousands with smart fixes. Follow me on LinkedIn:

Leave a Reply