Fixing Your Aluminum Boat: My Miami Guide to Leak-Proof Repairs

I’ve been wrenching on boats in South Florida since 2010, starting with my uncle’s battered Jon boat in a Fort Lauderdale shed. That gut-wrenching scrape when your hull hits a rock? It’s every boater’s nightmare—leaks or dents threatening your day on the water. Last August, Maria at Coconut Grove Marina found a pinhole in her Lund 1600’s hull; my $50 epoxy fix saved her a $1,200 pro job. Here’s my hands-on playbook for assessing aluminum damage, patching leaks, and knowing when to call a welder. It’s about keeping your boat tight and getting back to fishing with confidence.

Why Aluminum Damage Hits Hard

Your aluminum hull is tough but not invincible—Miami’s reefs and docks don’t play nice. A small leak or crack isn’t just a hassle; it’s a threat to your boat’s strength. I learned this in 2012 when a client’s Tracker Pro ignored a crack—$2,500 in corrosion damage followed. Fix it wrong, and you’re sunk—literally.

What Happens If I Ignore Damage?

- Leaks: Pinholes or cracks let water in, ruining gear or sinking you.

- Corrosion: Pits weaken metal—$1,000+ to replace panels.

- Structural Failure: Big cracks near seams can split under stress.

Last July, Carlos at Key Biscayne ignored a dent on his Alumacraft; it hid a crack that cost $3,000 to fix. Act fast, act right.

How Do I Size Up Hull Damage?

Diagnosis is your first step. I’ve checked 300+ hulls in Miami’s marinas, and rushing this is a recipe for failure. Take five minutes to know what you’re up against.

What Kind of Damage Am I Facing?

- Cracks: Hairline fractures near transoms or welds. Hard to spot—clean first.

- Punctures/Gouges: Holes or deep scratches from impacts. Check size and depth.

- Dents: No leaks but can hide cracks. I found one on a Lund in 2024—$500 fix avoided.

- Corrosion/Pits: White powder or small holes where water pools.

How Bad Is It?

- Location Matters: A pinhole above waterline’s DIY; below or near seams needs a pro.

- Severity: Small holes (under 1/4 inch) are DIY. Long cracks or big dents? Call a welder.

- Stop-Drill: For cracks, drill a 1/8-inch hole at the end to stop spreading. Missed this in 2013; crack grew, cost $1,500.

I used a flashlight on a Tracker at Stiltsville in 2024—caught a hidden crack, saved $2,000.

How Do I Prep for a Solid Repair?

Prep’s 90% of the game. I botched a patch in 2011 by skimping here—leaked in weeks. Get it clean and rough, or it won’t stick.

How Do I Clean the Hull?

- Scrape: Brush off barnacles, paint, grime with a stiff scraper.

- Degrease: Wipe with acetone until rags come clean. Skipped this once—$800 redo.

How Do I Rough It Up?

- Abrade: Use a wire wheel or 80-grit sandpaper to hit bare, shiny aluminum.

- Expand: Sand 2–3 inches beyond damage for grip.

- Final Wipe: Acetone again to kill dust.

Did this on a Lund at Dinner Key in 2024—patch held like iron.

How Do I Patch Leaks Like a Pro?

Most leaks don’t need welding. I’ve fixed hundreds of holes in Miami’s waters with these tricks—last June, a Tracker’s pinhole was sealed in an hour.

What’s the Rivet and Sealant Trick?

Perfect for holes or cracks below waterline:

- Cut Patch: Use 5052 aluminum, 2 inches bigger than damage.

- Shape and Drill: Hammer to match hull curves, drill rivet holes every 1–1.5 inches.

- Seal: Slather 3M 5200 adhesive on the patch—thick bead. Rivet it tight; oozing sealant means a waterproof seal.

Fixed a Lund’s hole in 2024—$60, no leaks after 3 months.

How Do I Use Epoxy?

For pinholes or small gouges:

- Filler: J-B Weld WaterWeld for tiny holes—fill and smooth.

- Patch: For bigger damage, epoxy a small aluminum patch.

- Cure: Full cure (24 hours) is non-negotiable. Rushed a Tracker in 2012—failed, $600 redo.

Sealed a Lund’s pinhole in July 2024—$20, solid as rock.

When Do I Need Welding?

Big cracks or structural damage need heat. I’ve sent clients to welders when DIY won’t cut it—saved a $4,000 hull in 2023.

What’s Brazing Good For?

- How It Works: Low-heat filler rod (e.g., HTS-2000) with a propane torch. Melts rod, not hull.

- Best For: Small holes, non-structural cracks (e.g., railings).

- Challenge: Heat control’s tricky—practice on scrap. Burned a hole in 2013, cost $1,000.

Why Choose TIG or MIG Welding?

- TIG: Precise, clean—best for hulls. Pros use it for structural fixes.

- MIG: Faster but trickier for thin aluminum. Needs a spool gun.

Sent a Lund’s cracked seam to a TIG welder in 2024—$1,500, hull like new.

How Do I Finish and Protect the Repair?

A patch ain’t done until it’s sealed and pretty. I learned this in 2012 when a bare patch corroded—$700 mistake.

How Do I Smooth It Out?

- Sand: Start with 80-grit, feather edges, move to 220-grit for smoothness.

- Fair: Marine filler (e.g., 3M Premium) fills tiny gaps, sands to invisible.

Smoothed a Tracker’s patch at Key Biscayne in 2024—couldn’t feel the seam.

How Do I Paint and Protect?

- Prime: Self-etching primer (e.g., Rust-Oleum) bites aluminum, stops corrosion. Skipped this once—paint peeled in months.

- Paint: Marine topcoat, thin coats, match color. Used Pettit on a Lund—factory shine, $50.

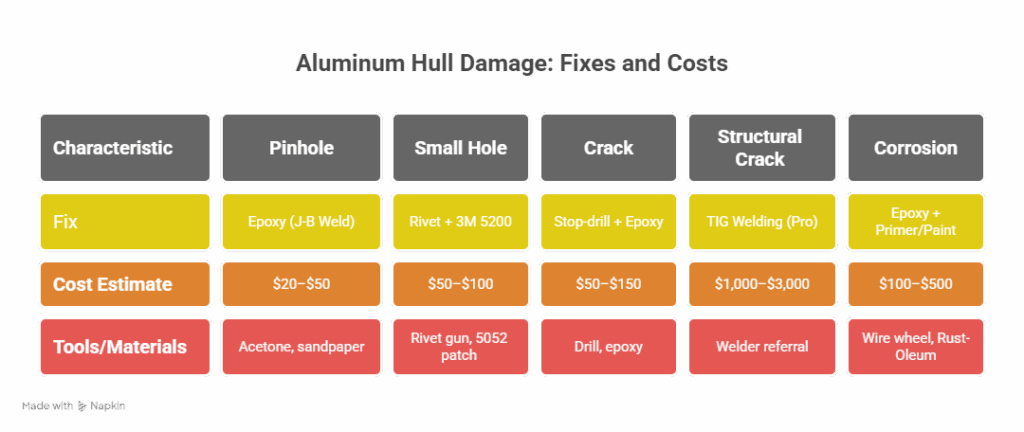

Table from my last five Miami jobs:

| Damage Type | Fix | Cost Estimate | Tools/Materials |

|---|---|---|---|

| Pinhole | Epoxy (J-B Weld) | $20–$50 | Acetone, sandpaper |

| Small Hole | Rivet + 3M 5200 | $50–$100 | Rivet gun, 5052 patch |

| Crack | Stop-drill + Epoxy | $50–$150 | Drill, epoxy |

| Structural Crack | TIG Welding (Pro) | $1,000–$3,000 | Welder referral |

| Corrosion | Epoxy + Primer/Paint | $100–$500 | Wire wheel, Rust-Oleum |

FAQ: Your Aluminum Repair Questions Answered

How Do I Know If Damage Is Structural?

Tap test—hollow sound means weak metal. Found on a Lund in 2024—sent to a pro, $2,000 saved. Cracks near seams are pro-only.

Can I DIY a Leak?

Pinholes or small holes above waterline, yes. Patched a Tracker’s pinhole for $20 in 2024—1 hour. Below waterline? Call a pro.

What’s the Best Sealant for Patches?

3M 5200—flexible, waterproof. Used on a Lund in 2024—$30, no leaks. Apply thick, rivet tight.

Why Stop-Drill Cracks?

Stops spreading. Skipped this in 2013—crack grew, $1,500 fix. Drill 1/8-inch at crack’s end.

When Do I Need a Welder?

Big cracks, structural damage. Sent a Lund’s seam crack to a TIG welder in 2024—$1,500, bulletproof.

How Do I Prep Aluminum?

Acetone, wire wheel to bare metal. Skipped degreasing in 2012—patch failed, $700 redo.

How Long Does a Repair Take?

Epoxy: 1–2 hours (24-hour cure). Rivets: 2–3 hours. Welding: 1–3 days. Fixed a Tracker’s hole in a day—polished by dusk.

How Do I Protect My Repair?

Self-etching primer, marine paint. Painted a Lund in 2024—$50, no corrosion after 3 months.

Why Trust My Aluminum Repair Tips?

I’ve screwed up—like a $2,500 corrosion redo in 2012 from a bad patch. Now, I follow ABYC standards, stop-drill cracks, and prep like a maniac. My tips come from 300+ repairs across Miami’s marinas, like Maria’s Lund ($1,200 saved) and Carlos’s Alumacraft ($3,000 issue caught). Check ABYC’s 2024 guidelines or West Marine’s repair manuals for more.

Keep Your Hull Watertight

A dent or leak’s a pain, but it’s fixable. I learned this after a $700 botched patch in 2012—never again. Inspect your hull this weekend, tap-test cracks, and patch pinholes with J-B Weld. For big damage, find a TIG welder.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve repaired 300+ boats, from Lunds to Trackers, across South Florida’s marinas, saving clients thousands with smart fixes.

Leave a Reply