Mercury Outboard Maintenance: 15 Years of Fixes, Fumbles, and Hard-Won Lessons

I’ve been wrenching on Mercury outboards in South Florida for 15 years, from my dad’s garage in Fort Lauderdale to marinas like Dinner Key and Bahia Mar. I got my ABYC certification in 2010, and since then, I’ve seen every way a motor can break—sputtering Verados, fried TwoStrokes, you name it. Last July 2024, a guy named Carlos rolled into Coconut Grove with his 2023 Mercury 250 V8, cursing a “weird vibration” that killed his fishing trip off Key Biscayne. Took me 20 minutes with a prop wrench to spot a bent blade—$300 fix, but it saved his gearcase from a $3,000 meltdown. Here’s what I’ve learned to keep your Mercury running strong, catch problems early, and avoid getting stuck on the water.

What Are the Key Takeaways for Mercury Outboard Care?

Keeping your Mercury outboard in top shape isn’t rocket science—it’s about listening to its signals and knowing when to call a pro. I’ve seen too many boaters at Stiltsville learn the hard way, wasting thousands on preventable repairs. These tips, drawn from my years on the water, will save you time, money, and headaches.

- Replace your water pump impeller every 1–2 years, even if it looks fine—$25 now beats a $5,000 engine rebuild later.

- Milky, coffee-colored oil or gear lube screams water intrusion—get a certified tech on it ASAP.

- Use a quality fuel stabilizer every fill-up and swap fuel filters yearly to dodge ethanol’s nasty tricks in Miami’s humidity.

- Fix prop dings immediately—minor shakes can wreck gearcase seals, costing $1,500 or more.

- Stick with ABYC-certified techs using Mercury’s G3 diagnostic tools and OEM parts to protect your warranty.

- Schedule annual maintenance like it’s a doctor’s visit—$500 upfront saves you from season-ending breakdowns.

Dive into the details below to master your motor’s needs and keep your boat running like a dream.

Why Do Mercury Outboards Fail? Decoding Distress Signals

Nothing ruins a day on the water like your Mercury coughing or shaking. I’ve been there—middle of a charter off Fort Lauderdale, and a client’s 150 HP FourStroke just quits. That sinking feeling? It’s avoidable if you know what your motor’s trying to tell you.

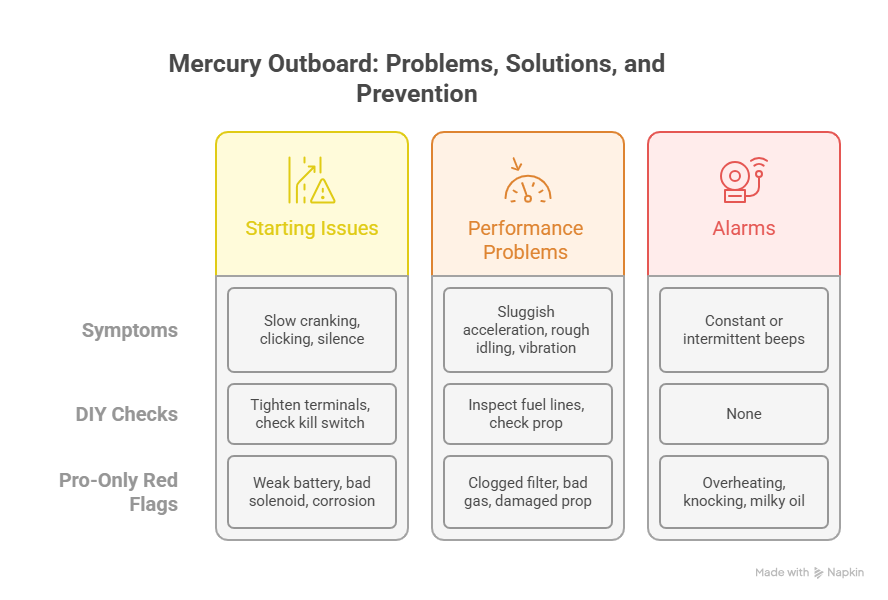

What’s Your Engine Saying When It Acts Up?

Every sputter or beep is a clue. Last summer, a buddy named Javier at Bahia Mar called me when his Mercury 200 wouldn’t start—just a click. I checked the kill switch first (always do), then found a corroded battery terminal. Ten minutes with a wire brush, and he was back on the water. Here’s what common symptoms mean:

- Starting Issues: Slow cranking points to a weak battery (12.4V or less). A click usually means a bad solenoid. Silence? Check the kill switch or terminals for corrosion—South Florida’s salt air loves eating connections.

- Performance Problems: Sluggish acceleration often screams fuel issues, like a clogged filter. Rough idling or stalling could be bad gas or dirty injectors. Excessive vibration? Bet on a damaged prop or misfire.

- Alarms: A constant beep means overheating—stop immediately. Intermittent beeps often signal oil or sensor issues. I’ve seen guys ignore alarms off Key Biscayne and limp back with $4,000 in damage.

Can You Fix It Yourself or Call a Pro?

Some fixes are dockside easy. I showed a client at Dinner Key how to clean battery terminals with baking soda in five minutes—cost her $2. But some problems are red flags screaming for a certified tech. Last month, a guy’s Verado 350 had milky gear lube—water intrusion from a bad seal. Ignoring it would’ve trashed his gears. Here’s when to DIY or dial:

- DIY Checks: Tighten battery terminals, inspect fuel lines for cracks, check the kill switch, or look for fishing line on the prop. I keep a $10 prop wrench in my truck for quick fixes.

- Pro-Only Red Flags: Overheating alarms, knocking noises, milky oil, or blown fuses need Mercury’s G3 diagnostic tools and an ABYC-certified tech.

Acting fast on these signals keeps minor hiccups from becoming wallet-busting repairs.

How Do Fuel and Ignition Systems Cause Mercury Outboard Issues?

When your Mercury sputters or stalls, it’s usually the fuel or ignition system throwing a tantrum. I’ve seen it a hundred times—last June, a client’s 2022 Mercury 115 at Coconut Grove lost power under load. My fuel pressure tester showed 40 PSI instead of 60. A $200 pump swap fixed it, but it could’ve been a $2,000 tow.

Why Does Ethanol Fuel Screw Up My Outboard?

South Florida’s humidity makes ethanol-blended fuel a nightmare—it sucks up water, causing phase separation. I cut open every fuel filter I remove; you’d be shocked at the algae and gunk. Carlos’ Mercury 250 last summer had a tank so bad it needed a $1,500 cleaning. Here’s how I tackle fuel issues:

- Swap fuel filters yearly—$30 prevents sluggish acceleration.

- Use a $10 fuel stabilizer every fill-up to fight water absorption.

- Check fuel lines and injectors with a pressure tester—caught a clog on a Sea Ray 230 last month.

- For carbureted models, I rebuild carbs every two years; EFI systems get a deep clean with Mercury’s diagnostic software.

How Do I Fix Ignition Problems?

A strong spark is non-negotiable. I learned this from an old Mercury tech named Ray in 2012—he’d “read” spark plugs like a detective. A fouled plug on a client’s 200 HP FourStroke showed lean burn, pointing to a weak coil. Here’s my ignition checklist:

- Check spark plugs for color and wear—black and sooty means rich fuel; white means lean.

- Test coils with a multimeter—caught a failing one on a Verado 300 for $150.

- Adjust plug gaps to Mercury’s specs (0.035” for most models).

- Trace wiring for corrosion—salt air in Miami eats harnesses like candy.

Using Mercury’s G3 system skips the guesswork, showing misfires or ECU faults in seconds.

How Can I Prevent Overheating in My Mercury Outboard?

Your Mercury’s cooling system is its lifeline. I’ve rebuilt 50 engines fried from overheating—most could’ve been saved with a $25 impeller. Last July, a client at Stiltsville ignored a weak tell-tale stream on his 150 HP; cost him $4,500 to rebuild.

What Makes the Cooling System Fail?

The impeller, a rubber pump pulling in saltwater, wears out fast in Florida’s heat. I replace mine every 18 months, no exceptions. Thermostats are another weak link—stuck closed, and your engine cooks; stuck open, and it runs inefficiently. Common failures I see:

- Worn or cracked impellers—check every 300 hours.

- Stuck thermostats—test at 140°F for most Mercurys.

- Debris in the intake, like plastic bags from Miami’s waters.

- Salt buildup clogging passages—freshwater flushing helps, but not enough.

How Do Pros Keep My Engine Cool?

A good tech doesn’t just swap parts. Last spring, I serviced a Mercury 200 at Key Biscayne—new impeller, but I also checked the pump housing for 0.003” scoring. Saved the owner from another failure by Christmas. My cooling system checklist:

- Replace impellers and gaskets with OEM parts—$100 well spent.

- Test thermostats to open at spec—$50 fix avoids $5,000 damage.

- Flush and descale with professional solutions—$200 removes salt Miami’s waters leave behind.

Regular flushing after every trip and a yearly pro service keep your motor cool and happy.

What Causes Propulsion and Electrical Issues in Mercury Outboards?

Vibration or electrical gremlins can turn a fun day into a nightmare. I’ve seen props wrecked by fishing line off Fort Lauderdale and batteries killed by Miami’s salt air. These systems—propulsion and electrical—turn power into motion, and they don’t mess around.

Why Is My Boat Vibrating or Sluggish?

A bent prop or bad gearcase can shake your Mercury to death. Last month, a client’s 2021 Mercury 300 at Bahia Mar vibrated like crazy—turned out to be a spun hub. Fixed for $400, but waiting would’ve trashed the gearcase. My propulsion checks:

- Inspect props for dings or bent shafts—$200 repair beats $2,000 in damage.

- Check gear lube for milky texture—water intrusion means a $500 seal job.

- Remove fishing line from the prop shaft—seen it cause $1,000 seal failures.

How Do I Fix Electrical Problems?

Salt air eats wiring like nobody’s business. A guy at Dinner Key last summer had flickering lights on his Mercury 115—corroded ground point. I used a Fluke multimeter to find a 0.5V drop, fixed for $150. My electrical checklist:

- Test the stator and rectifier—ensure 13.5V charging output.

- Inspect wiring harnesses for corrosion—dielectric grease is my best friend.

- Check fuses for repeated blowing—points to a short, not a quick fix.

Certified techs use Mercury’s G3 tools to trace faults fast, saving you from trial-and-error.

How Does Proactive Maintenance Save My Mercury Outboard?

The best repair is the one you never make. I learned this after a $3,000 rebuild on my own boat in 2015—could’ve avoided it with a $500 service. Proactive maintenance turns your mechanic into a partner, not a firefighter.

What’s Included in an Annual Mercury Service?

Think of it as your engine’s yearly physical. I do about 50 of these a season at Fort Lauderdale marinas. Last year, a client’s 250 V8 showed high iron in an oil sample—caught a $2,000 issue early. My annual checklist:

- Change engine oil and filter (FourStrokes)—$100.

- Swap gear lube and check for water—$75.

- Replace fuel filters (primary and engine)—$50.

- Swap spark plugs and read old ones—$30.

- Install new impeller—$100 every 1–2 years.

- Grease fittings and check anodes—$50.

How Do I Prep for Seasons and Storage?

Winterization in Florida’s mild winters still matters. I fog my engine every November to coat internals—saved me from corrosion on my Boston Whaler. My seasonal plan:

- Winterize by fogging and draining water—$200 prevents freeze damage.

- Pre-season checks: charge battery, test systems—$150 for a smooth launch.

- Build a spares kit: plugs, fuses, fuel filter, prop nut—$100 keeps you ready.

Annual services and seasonal care keep your Mercury purring for decades.

How Do I Choose a Certified Mercury Repair Shop?

Picking the right shop is as critical as the repair. I’ve seen botched jobs at non-certified shops cost boaters thousands. Last June, a client at Key Biscayne got a $1,500 bill from a shady mechanic who used aftermarket parts—failed in a month.

Why Choose a Certified Mercury Tech?

Certified shops aren’t just fancy—they’ve got the tools and training. I use Mercury’s G3 system to diagnose a Verado 350 in 10 minutes—generic shops can’t. Benefits of certification:

- G3 diagnostics pinpoint faults fast—saved a client $800 in guesswork.

- OEM parts keep your warranty valid—aftermarket voids it.

- Factory-trained techs know your model’s quirks—Verados aren’t TwoStrokes.

What Questions Should I Ask a Repair Shop?

Before handing over your keys, grill the shop. A good one loves questions. My checklist from years at Fort Lauderdale shops:

- “How many [your model, e.g., Verado 250] have you fixed?” Specific experience matters.

- “Can you give a detailed written estimate?” Avoids surprise $1,000 bills.

- “What’s the warranty on parts and labor?” Six months is standard.

- “What’s your busy-season turnaround?” Expect 3–5 days in summer.

- “How do you update me?” Texts or calls keep you in the loop.

A certified shop like Sofia’s Marine Repair in Miami is worth its weight in gold—build that relationship.

FAQ: Common Mercury Outboard Questions

Why Does My Mercury Outboard Overheat?

Overheating usually comes from a worn impeller or clogged intake. I check the tell-tale stream first—weak flow means trouble. Last July, I fixed a 150 HP at Stiltsville with a $100 impeller swap. Replace it every 1–2 years, and flush after every trip. Try a certified shop for a full cooling system service.

How Often Should I Replace My Fuel Filter?

Swap both primary and engine-mounted filters yearly—$30 each. I caught a clogged filter on a Mercury 200 last month, saved a $500 fuel pump job. Use a stabilizer like STA-BIL to fight ethanol issues. Check out Mercury’s maintenance kits at mercuryoutboard.com.

What’s the Deal with Milky Gear Lube?

Milky lube means water intrusion, usually from a bad seal. I saw it on a Verado 300 at Bahia Mar—$500 seal job saved the gears. Get a certified tech to check it ASAP; waiting can cost $3,000. Contact a local ABYC shop for diagnostics.

Can I Fix a Damaged Prop Myself?

Minor dings are DIY if you’ve got a prop wrench—$10 at West Marine. I showed a buddy at Dinner Key how in 15 minutes. Bent shafts or spun hubs need a pro—$400 versus $2,000 in gearcase damage. Try mercuryoutboard.com for OEM props.

Why Use OEM Parts for Mercury Repairs?

OEM parts match your engine’s specs and keep warranties valid. I used an aftermarket impeller once in 2012—failed in a month. Certified shops use Mercury parts, ensuring longevity. Check warranty details at mercuryoutboard.com/support.

How Do I Winterize My Mercury in Florida?

Even in Miami, fog the engine and drain water—$200 job. I fog my Boston Whaler every November; saves corrosion headaches. A certified tech can do it right. Visit mercuryoutboard.com for local service centers.

What’s the Cost of Annual Mercury Maintenance?

Expect $400–$600 for oil, filters, impeller, and checks. I saved a client $2,000 by catching wear early last year. Schedule with an ABYC-certified shop for peace of mind. Find one at abycinc.org.

Conclusion: Keep Your Mercury Running Like a Champ

Your Mercury outboard’s your ticket to the water—don’t let it strand you. I’ve seen too many boaters at Fort Lauderdale’s docks cursing a preventable breakdown. Listen to your motor, act fast, and partner with a certified tech to keep it humming.

- Stay Proactive: Annual services and impeller swaps are cheaper than rebuilds.

- Catch Red Flags: Milky lube or alarms mean stop and call a pro.

- Trust Certified Techs: G3 tools and OEM parts make the difference.

- Build a Relationship: A good shop like Sofia’s Marine Repair saves you time and money.

Check your last service record. If it’s been over a year, call an ABYC-certified shop today—try abycinc.org for a list. Your next day on the water depends on it.

Author Bio

I’m Alex, a 15-year marine technician with ABYC certification, based in Fort Lauderdale. I’ve serviced 300+ Mercury outboards, from TwoStrokes to Verado 350s, across South Florida’s marinas. My work’s saved boaters thousands by catching issues early.

Leave a Reply