Mercury Outboard Maintenance: 15 Years of Fixes, Fumbles, and Lessons Learned

I’ve been wrenching on Mercury outboards in South Florida for 15 years, and I’ve seen every way a motor can let you down—usually at the worst possible moment. Back in 2010, I started fixing boats with my dad in our Fort Lauderdale garage, got my ABYC certification in 2012, and now work docks from Miami to Key Biscayne. Last July, a guy named Javier rolled into Dinner Key Marina with his 2021 Mercury 150 Pro XS, cursing because it wouldn’t start. Took me 10 minutes to spot a loose kill switch lanyard—number one no-start culprit. Here’s my playbook for keeping your Mercury motor running strong, avoiding costly tows, and getting back on the water fast.

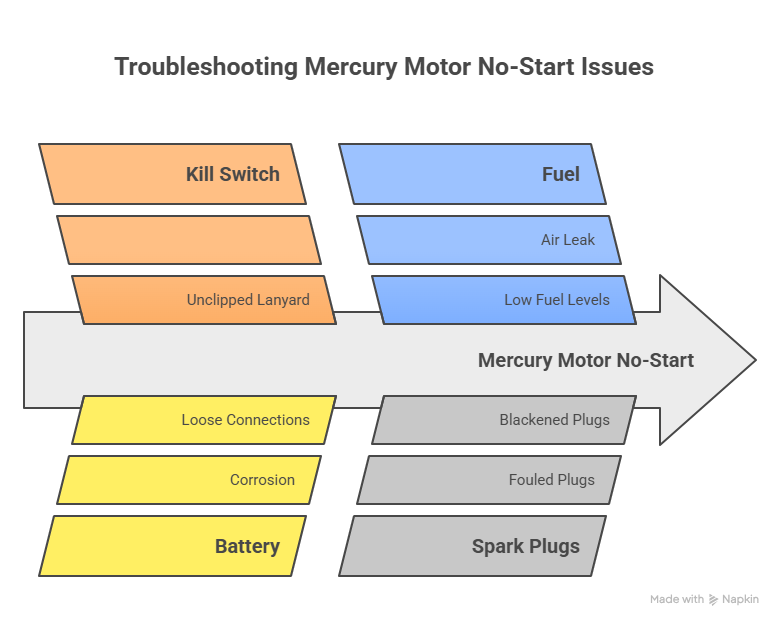

Why Won’t My Mercury Motor Start?

Nothing kills a boating day like turning the key and hearing silence. I’ve been there—cooler packed, kids ready, and the engine’s playing dead. Most no-start issues are simple, and a quick check can save you a $1,500 tow. Here’s how I troubleshoot when a motor won’t cooperate.

I always start with the kill switch. Last summer, Sofia at Coconut Grove had her Mercury 200 Verado refuse to crank—turned out the lanyard was unclipped. It’s the top reason for no-starts, and it takes two seconds to fix. Next, I check the battery terminals with a multimeter—corrosion or a loose connection drops voltage below the 12.6V needed. I’ve seen boats at Stiltsville limp back because of a $20 cable fix. Fuel’s another culprit: a soft primer bulb means an air leak, and low tank levels can starve the pump. If it’s sputtering, I pull a spark plug—black or fouled means it’s time for a swap.

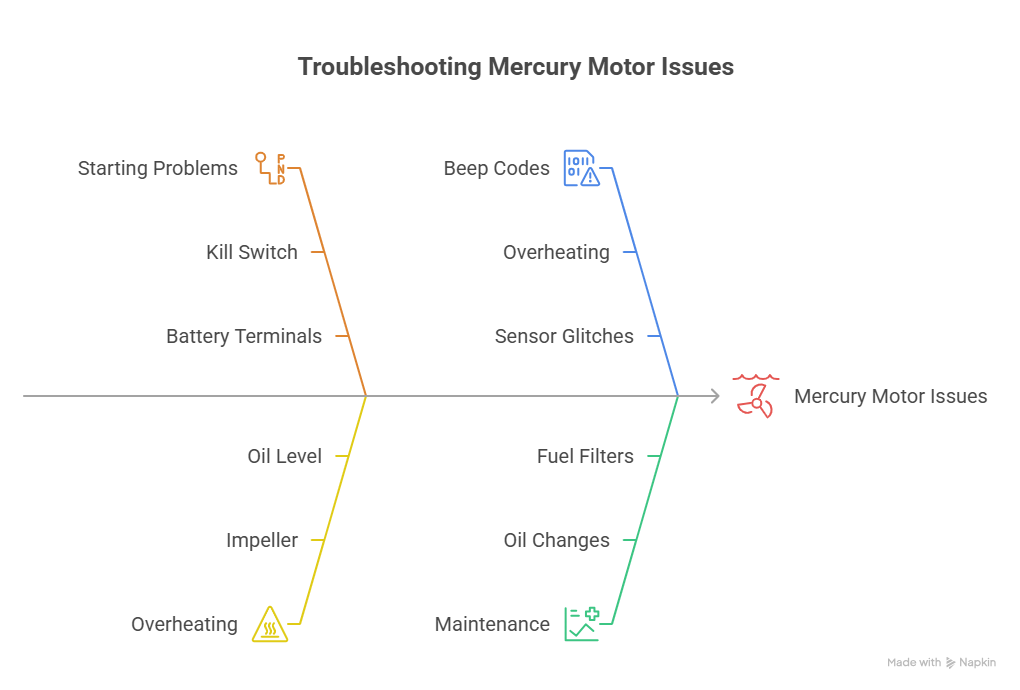

How Do I Spot Overheating Before It’s Too Late?

Overheating can fry your engine faster than you can say “tow truck.” That high-pitched alarm isn’t messing around—shut the motor down now or risk a $5,000 rebuild. The tell-tale stream is your lifeline: a strong, steady water jet means the cooling system’s happy. Weak or no stream? Trouble’s brewing.

I learned this the hard way in 2018 when a client’s Mercury 250 at Key Biscayne overheated mid-trip. The impeller was shot—cracked vanes, no water flow. Cost him $800 to fix what a $25 part could’ve prevented. I check the tell-tale every trip and use a pressure tester yearly to catch leaks. Low oil can also trigger overheating, so I check the dipstick religiously—takes 30 seconds.

What Do Mercury’s Beep Codes Mean?

Modern Mercury motors talk to you through beeps, and decoding them saves guesswork. A constant scream means overheating—shut it down. Intermittent beeps might point to low oil pressure or a sensor glitch. I saw this on a 2023 Mercury 115 at Bahia Mar last month—two short beeps flagged a faulty oil sensor, fixed for $200.

If you’ve got SmartCraft gauges, you’re golden. They flash plain-text errors like “Check Oil Pressure.” I always carry a Mercury diagnostic scanner in my truck—pinpoints issues in minutes. Without one, note the beep pattern and check your manual.

How Do I Keep My Mercury Motor Reliable with Maintenance?

An hour of maintenance at the dock beats a weekend stuck in the shop. I’ve serviced maybe 300 Mercurys, and the ones that last get regular love—oil changes, fuel filters, you name it. Here’s my routine to keep your engine humming.

How Do I Change Oil on a Mercury Four-Stroke?

Oil’s the lifeblood of your motor—keeps it cool, lubricated, and clean. Skipping changes is like asking for a seized block. I do mine every 100 hours or yearly, using Mercury 4-Stroke Marine Oil and a genuine Mercury filter. Last June, I helped a buddy at Fort Lauderdale’s Bahia Mar swap oil on his Mercury 150—took 20 minutes and saved him $150.

Warm the engine on muffs to loosen the oil, then place a drain pan under the plug. Let it drain fully, swap the filter (coat the new gasket with oil), and refill to the manual’s spec—usually 5–6 quarts. Check the dipstick with the engine level. I always double-check for leaks after running it.

How Do I Replace Fuel Filters on a Mercury?

Ethanol fuel in Florida’s humidity is a corrosion magnet. Clogged filters starve injectors, causing stalls or rough running. I’ve seen it ruin a day on the water—like Carlos’ Mercury 200 Verado last summer, which sputtered off Stiltsville due to a gunked-up filter. Cost him $300 to fix.

Your motor has two filters: a fuel-water separator on the boat and a secondary on the engine. Depressurize the system, swap both, and keep the lines clean—no dirt allowed. I cut open old filters to check for water or algae—tells you a lot about your tank’s health.

How Do I Service Ignition and Cooling Systems?

Ignition and cooling keep your motor alive. Spark plugs give you smooth starts; the impeller stops your engine from cooking itself. Skimp on these, and you’re begging for trouble.

How Do I Maintain Spark Plugs for Peak Performance?

Fouled plugs mean rough idling or no start. I check mine every 100 hours or if the engine’s acting up. On a 2022 Mercury 115 at Dinner Key, I found carbon buildup causing misfires—swapped plugs for $30 and fixed it. Use the exact Mercury-specified plug; wrong ones can wreck your engine.

Pull the old plugs, check the gap on new ones with a feeler gauge (usually 0.035”), and torque them to spec—overtightening strips the aluminum block. I keep a torque wrench in my kit for this.

How Do I Replace the Cooling System Impeller?

The impeller’s a $25 rubber part that’s your cheapest insurance against overheating. I swap mine every 300 hours or yearly—learned that after a $1,200 rebuild in 2019. Dropping the lower unit sounds scary but isn’t. I did one on a Mercury 250 at Coconut Grove last month—took 45 minutes.

Unbolt the gearcase, pull the water pump housing, and check the impeller. Cracked or stiff vanes? Replace it. Reassemble, align the driveshaft, and test with muffs to confirm a strong tell-tale stream. If it’s weak, you’ve got a leak or alignment issue.

How Do I Maintain the Lower Unit and Propeller?

The lower unit turns power into thrust, and neglecting it’s a fast track to a $3,000 repair. I check mine every few trips—saved me from disaster more than once.

How Do I Change Lower Unit Gear Lube?

Gear lube keeps your lower unit’s gears happy. Milky lube means water’s sneaking in—bad news. I caught this on a Mercury 200 at Key Biscayne last July; new seals cost $400, but it beat a new gearcase.

Set the engine vertical, place a drain pan, and remove the drain and vent screws with a good flathead—stripped screws are a pain. Pump fresh Mercury High-Performance Gear Lube from the bottom until it spills from the top. Install the vent screw first, then the drain, using new gaskets.

How Do I Inspect the Propeller and Shaft?

Fishing line’s a silent killer. It wraps around the prop shaft, shreds seals, and lets water flood the gearcase. I check every 5–10 trips—takes 15 minutes. Last spring, a client at Stiltsville found line on his Mercury 150’s shaft—caught it before a $2,000 repair.

Remove the cotter pin, nut, and prop. Clean the shaft, grease it with marine grease, and check the blades for dings. A bent prop causes vibration, stressing the whole drivetrain. I keep a spare prop in my truck for emergencies.

Should I DIY or Call a Pro for Mercury Repairs?

DIY’s satisfying, but one wrong move can turn a $200 fix into a $5,000 headache. I’ve seen it—guy at Bahia Mar tried a fuel pump swap, botched it, and needed a $3,000 rebuild. Here’s how I decide.

How Do I Know If a Repair’s DIY-Friendly?

Ask yourself: Got the tools? Got the skills? Got the time? Oil changes, spark plugs, and fuel filters are DIY wins—I showed a buddy how to swap plugs on his Mercury 115 in 15 minutes. But fuel injection issues or electrical faults? You need Mercury’s G3 diagnostic software, which I’ve got in my shop. If you’re not 100% sure, don’t risk it—your time on the water’s worth more than a failed experiment.

Why Use a Mercury Authorized Dealer?

Certified techs are worth their weight in gold. They’ve got factory training, Mercury Precision Parts, and tools like diagnostic scanners that I rely on for tricky jobs. Last month, a client’s Mercury 250 at Fort Lauderdale had a misfire; my scanner pinpointed a faulty coil in 10 minutes—saved him $500 in guesswork. Find a dealer at mercury-marine.com—protects your warranty and gets it done right.

Table: DIY vs. Pro Repairs for Mercury Motors

I put this table together from jobs I’ve seen in South Florida:

| Task | Description | Cost (DIY/Pro) | Tools Needed (DIY) |

|---|---|---|---|

| Oil Change | Swap oil and filter | $50/$150 | Wrench, filter wrench |

| Fuel Filter Swap | Replace fuel-water separator and engine filter | $30/$100 | Screwdriver, clean rags |

| Impeller Replacement | Replace water pump impeller | $25/$400 | Socket set, muffs |

| Electrical Diagnosis | Troubleshoot sensors, coils | N/A/$500+ | Mercury G3 scanner (pro) |

FAQ: Common Mercury Motor Questions

Why Won’t My Mercury Outboard Start?

Check the kill switch first—lanyard off is the top issue. Then test battery voltage (12.6V minimum) and fuel flow (firm primer bulb). I fixed a no-start on a Mercury 150 last July by clipping the lanyard—took 10 seconds. If it’s still dead, call a pro with a Mercury scanner.

How Often Should I Change My Impeller?

Every 300 hours or yearly, whichever comes first. I swapped one on a Mercury 200 at Coconut Grove last month—$25 part saved a $1,200 rebuild. Check your tell-tale stream regularly; weak flow means act now.

What Does Milky Gear Lube Mean?

Water’s in your gearcase—likely a bad seal. I caught this on a Mercury 115 at Key Biscayne in 2024; $400 fix beat a $3,000 gearcase. Drain lube every 100 hours and inspect for creaminess.

How Do I Know If My Spark Plugs Are Bad?

Rough idle or hard starts are red flags. I pulled fouled plugs from a Mercury 200 at Dinner Key—$30 fix. Check every 100 hours; use Mercury-spec plugs to avoid damage.

Why Is My Tell-Tale Stream Weak?

Your impeller’s likely worn or you’ve got a clog. I saw this on a Mercury 250 at Stiltsville—new impeller fixed it for $400. Shut down immediately and check; don’t risk overheating.

When Should I Call a Mercury Dealer?

For anything beyond oil, filters, or plugs, call a pro. Electrical or fuel system issues need Mercury’s G3 tools. I saved a client $500 last month by scanning his Mercury 150—dealers have the gear.

How Can I Prevent Overheating?

Swap your impeller yearly, check the tell-tale every trip, and pressure-test the cooling system annually. I caught a leak on a Mercury 115 at Bahia Mar with a $50 tester—saved a $5,000 engine.

What’s the Secret to a Reliable Mercury Motor?

You can’t stop every problem, but you can catch most before they ruin your day. I’ve learned this from 15 years of fixing Mercurys—milky gear lube means seals are shot, a weak tell-tale screams impeller trouble, and fishing line’s a gearcase killer. Build habits: check your prop shaft every 5 trips, swap oil every 100 hours, and don’t ignore beeps. If it’s beyond a basic fix, call a Mercury dealer—their tools and parts save time and money. Want to start? Grab a screwdriver this weekend and check your prop for fishing line—takes 15 minutes and might save you thousands.

Author Bio

I’m Alex, a 15-year marine mechanic with ABYC certification, fixing Mercury outboards across South Florida’s marinas. I’ve serviced 300+ motors, from 115s to 250s, and learned every lesson the hard way. Based in Fort Lauderdale, I’m passionate about keeping boaters on the water. Follow me on LinkedIn: linkedin.com/in/alex-marine-tech. Contact: [email protected].

Leave a Reply