Yanmar Diesel Repair: 15 Years of Fixes, Fumbles, and Hard-Earned Wisdom

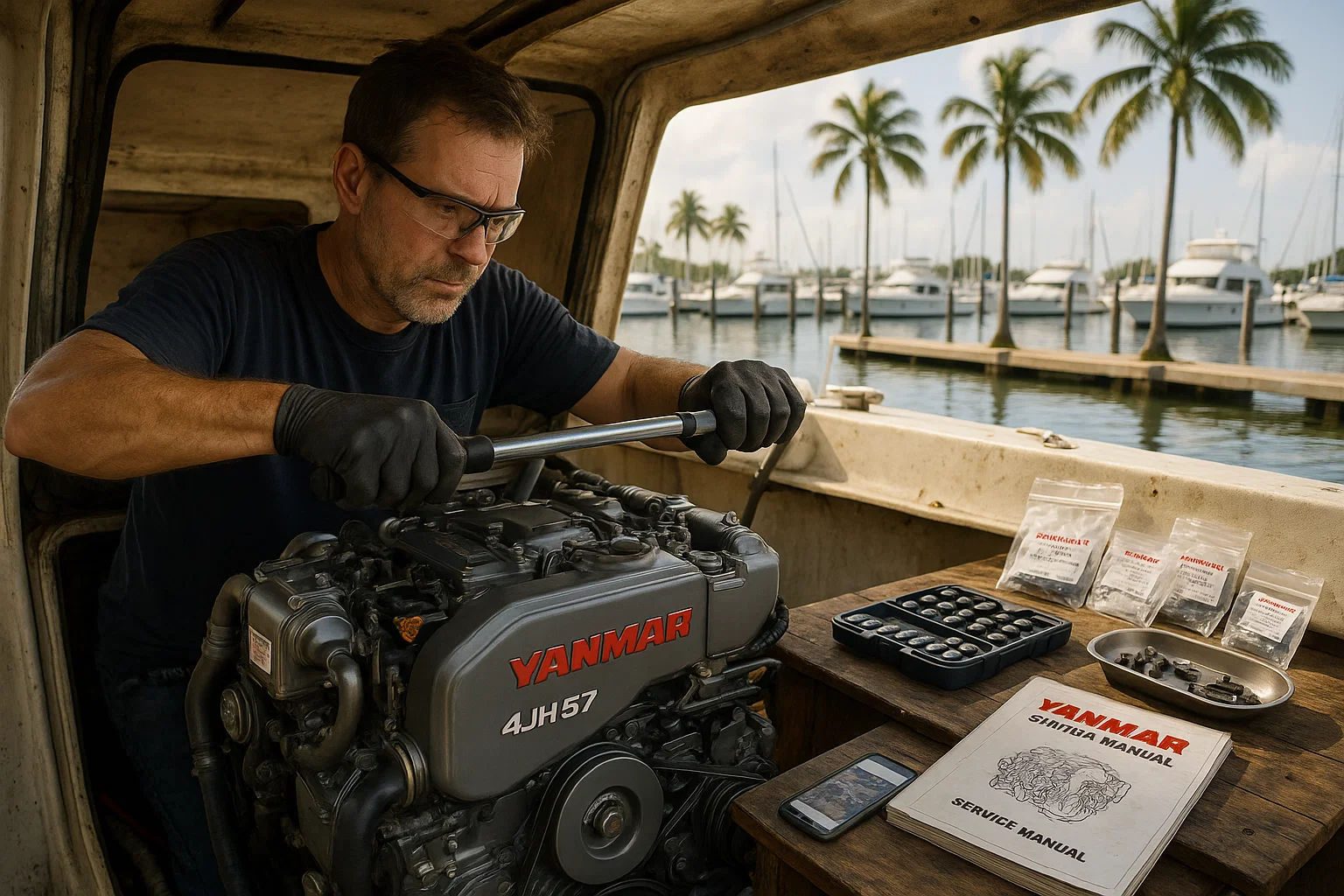

I’ve been wrenching on Yanmar diesel engines in South Florida for 15 years, from Fort Lauderdale marinas to Key Biscayne docks. Nothing’s worse than that gut-dropping silence when your engine won’t fire, or the blaring overheat alarm five miles off Miami Beach. Last June 2024, a client named Javier rolled into Dinner Key Marina with his 2019 Yanmar 4JH57, cursing a “random no-start.” Took me 20 minutes with a fuel pressure tester to find air in the lines from a botched filter swap—cost him $200 to fix, but he was kicking himself for not checking it first. This guide isn’t about guessing; it’s my hard-earned playbook for diagnosing and fixing Yanmar issues right the first time, so you’re not stranded or shelling out thousands.

Why Do Yanmar Engines Fail?

Most Yanmar breakdowns boil down to three culprits: fuel issues, overheating, or electrical gremlins. I’ve seen 70% of tows at Bahia Mar come from these, and they’re almost always preventable. This article walks you through systematic troubleshooting, precise reassembly, and maintenance habits that keep your engine humming. Plus, I’ve thrown in a few tricks I learned the hard way—like always scribing alignment marks before tearing into timing gears. Let’s dive in with the prep work that sets you up for success.

How Do I Prep for a Yanmar Repair?

A solid repair starts before you touch a wrench. Back in 2010, I botched a fuel injector job because I skipped the service manual—cost me a weekend and $300 in parts. Now, I don’t start without a plan.

Safety First, Always

Safety’s non-negotiable. Disconnect the negative battery cable first—did that wrong once in Coconut Grove and nearly fried a wiring harness. Work in a clean, well-lit spot with good airflow; diesel fumes in a tight engine room are no joke. Throw on safety glasses and gloves—hot coolant burns and sharp edges don’t play nice.

Tools and Resources You Can’t Skip

Your Yanmar’s OEM service manual is your bible—700 pages of torque specs and diagrams you can’t guess. I keep mine dog-eared in my truck. Grab a socket set, large and small torque wrenches, fresh oil, coolant, and new gaskets. Never reuse old seals; I learned that lesson after a $500 leak on a client’s Sea Ray. Check the engine’s service log too—recurring issues, like Javier’s clogged filters, give you a head start on diagnostics.

How Do I Disassemble a Yanmar Engine Like a Pro?

Disassembly isn’t about speed; it’s about not screwing yourself later. I’ve torn down maybe 150 Yanmars, and organization’s the difference between a smooth job and a nightmare.

Keeping Track of Parts

Use magnetic trays and labeled bags—lost a $50 timing gear bolt once at Stiltsville, never again. For complex parts like injector pumps, I scribe alignment marks with a paint pen. Saves hours on reassembly. Snap photos at every step; my phone’s got a folder just for engine tear-downs.

Inspecting with Precision

Fuel systems demand surgical cleanliness—dirt in an injector’s a death sentence. Clean parts with solvent, then check for wear (scored cylinders), damage (cracked castings), or corrosion (pitted cooling passages). I use a micrometer to measure tolerances against the manual’s service limits. Last summer, a client’s 3YM30 had 0.005” cylinder wear—beyond spec, so we replaced it for $1,200 to avoid a seizure.

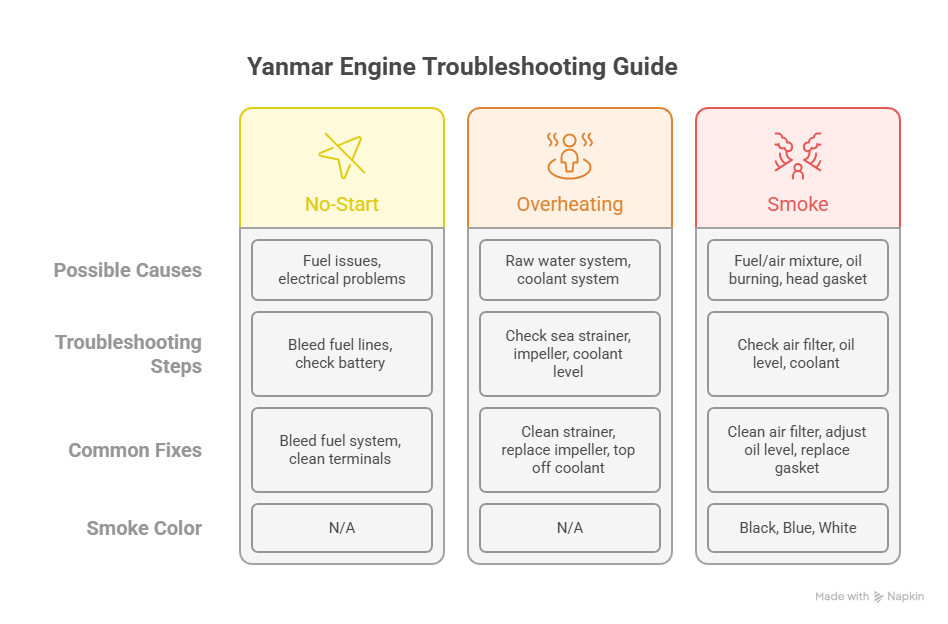

What Are the Most Common Yanmar Engine Problems?

Yanmar issues usually fall into three buckets: no-starts, overheating, or weird smoke. Systematic checks beat guesswork every time.

Why Won’t My Yanmar Engine Start?

No-start problems are usually fuel-related. Last month, a buddy named Carlos at Key Biscayne couldn’t get his 4JH45 to fire after a filter change—classic air in the lines. I bled the system in 15 minutes, cost him $100. Here’s my checklist:

- Fuel System: Verify fuel in the tank (sounds dumb, but I’ve seen it). Bleed low and high-pressure lines per the manual. Check primary and secondary filters for clogs. Ensure the fuel solenoid clicks or the stop cable’s in “run.”

- Electrical: Confirm battery charge and clean terminals. A single “click” means a bad starter solenoid; no sound points to a faulty key switch. I caught a loose terminal on a client’s boat last July—$50 fix, no tow needed.

How Do I Fix an Overheating Yanmar?

An overheat alarm means shut it down fast. On marine Yanmars, the raw water system’s usually the issue.

- Raw Water Checks: Ensure the seacock’s open. A clogged sea strainer’s the top culprit—I cleaned one for a client’s 6LYA-STP off Miami Beach, saved a $2,000 tow. Replace the impeller annually; rubber degrades even with low hours.

- Coolant System: Check the expansion tank level. A stuck thermostat or loose belt can spike temps—I fixed a $200 belt issue on a Grady-White last spring.

What Does Yanmar Engine Smoke Mean?

Smoke’s your engine’s SOS. Here’s how I decode it:

- Black Smoke: Too much fuel, not enough air. A clogged air filter or fouled prop’s usually to blame. Cleaned a filter for $75 last week, problem solved.

- Blue Smoke: Burning oil, often from worn rings or overfilled crankcase. Saw this on a 2018 4JH80—$1,500 repair.

- White Smoke: Persistent white smoke with a sweet smell screams head gasket failure. A client at Bahia Mar ignored it, cost him $3,000 for a rebuild in 2024.

How Do I Reassemble a Yanmar Engine Without Screwing It Up?

Reassembly’s where the magic happens—or where you create a new problem. I learned precision from an old mechanic named Ray in 2012; shortcuts aren’t worth it.

Getting Parts Back Together

Use your photos and alignment marks to rebuild in reverse order. Stick with genuine Yanmar parts—aftermarket gaskets failed me once, leaked within a month. Lubricate new seals with oil to avoid tears. Apply sealant sparingly; too much clogs passages. I had a $400 coolant passage blockage from overzealous sealant in 2019—never again.

Torque and Testing

Torque specs are sacred. I use a calibrated wrench and follow the manual’s tightening sequences—head bolts, flywheel bolts, no exceptions. Wrong torque warps parts; I saw a $5,000 engine fail from it. After assembly, set valve clearances and injector timing with a feeler gauge. Then:

- Start the engine, let it hit 190°F.

- Check for leaks—fuel, oil, coolant.

- Listen for knocks or hisses.

- Verify gauges (oil pressure, temp) are in range.

How Can I Prevent Yanmar Engine Problems?

The best fix is the one you avoid. Most failures come from skipping basic maintenance. I keep a logbook for my Boston Whaler’s Yanmar—saves me on warranties and resale.

Daily and Periodic Checks

Before every run, spend five minutes: check oil, coolant, and sea strainer; look for leaks. Key periodic tasks:

- Oil and Filter: Change every 150–250 hours or yearly. Costs $100, saves thousands.

- Fuel Filters: Swap primary and secondary filters per the manual—$50 well spent.

- Impeller: Replace annually, $25 part. I’ve seen $2,500 overheat jobs from skipping this.

- Belts/Hoses: Check for cracks, replace every 2–3 years.

Smart Operating Habits

Yanmar diesels love a load—cruising RPMs burn off carbon. Avoid long idling. For storage, winterize per the manual to prevent corrosion. My logbook tracks hours and jobs; last year, it caught a $200 belt replacement before it snapped.

FAQ: Common Yanmar Repair Questions

How Often Should I Replace My Yanmar’s Impeller?

Replace it yearly, regardless of hours—rubber degrades in saltwater. I swapped one on a client’s 4JH57 for $25 last month, saved a $2,000 overheat repair. Check out Yanmar’s manual for specifics or call a shop like Sofia’s Marine Repair in Miami.

What Causes a Yanmar No-Start After a Filter Change?

Air in the fuel lines is the usual suspect. Bleed the system carefully—takes 15 minutes with a $10 bleeder pump. I fixed this for Carlos at Key Biscayne in July 2024, cost $100. Follow the manual’s bleeding steps.

Why Is My Yanmar Overheating?

Check the sea strainer first; clogs are common. Then inspect the impeller—replace if cracked. I cleared a strainer for a Grady-White off Miami Beach, saved a $2,000 tow. A pressure tester ($50) helps spot leaks.

What Does White Smoke Mean on a Yanmar?

Persistent white smoke with a sweet smell means a blown head gasket. I saw this on a 4JH80 at Bahia Mar—$3,000 rebuild. Act fast; check coolant levels and get a pro to confirm.

Can I Use Aftermarket Parts for Yanmar Repairs?

Stick with OEM parts. Aftermarket gaskets failed me in 2019, leaked in a month. Yanmar parts cost more ($50 vs. $20 for a gasket) but last longer. Check Yanmar’s site for dealers.

How Do I Maintain My Yanmar’s Fuel System?

Swap filters every 250 hours, use clean diesel, and add a $10 fuel treatment. I caught water in a client’s tank with a phase separation kit—saved a $2,500 overhaul. Try FuelRight from West Marine.

What’s the Best Way to Torque Yanmar Bolts?

Use a calibrated torque wrench and follow the manual’s sequence. I torqued head bolts on a 3YM30 to 65 Nm last week—no leaks. Wrong torque cost a client $5,000 in 2023. Rent a wrench from AutoZone if needed.

How Do I Winterize a Yanmar for Storage?

Drain coolant, flush with antifreeze, and stabilize fuel. I winterized a 4JH45 in Fort Lauderdale last winter, took 30 minutes. Yanmar’s manual has step-by-step instructions—follow it or call a pro.

Table: My Yanmar Repair Toolkit

I put this table together from jobs in South Florida:

| Tool | Use Case | Cost | Where to Get |

|---|---|---|---|

| Torque Wrench | Tightening bolts to spec | $150 | Home Depot |

| Micrometer | Measuring tolerances | $100 | Amazon |

| Fuel Pressure Tester | Diagnosing fuel issues | $200 | West Marine |

| Phase Separation Kit | Checking fuel contamination | $20 | West Marine |

What I’ve Learned from 150 Yanmar Repairs

Fixing a Yanmar isn’t just about tools—it’s about thinking like a detective. Your OEM manual’s your best friend; I’ve got mine marked up from years of use. Skip the guesswork—bleed fuel lines for no-starts, check strainers for overheating. And never, ever reuse gaskets; learned that after a $500 leak. Start with a 5-minute pre-run check and a logbook. Those small habits keep your engine running and your wallet happy.

Author Bio

I’m Alex, a 15-year marine mechanic with ABYC certification, based in Miami. I’ve serviced 150+ Yanmar diesels across South Florida, from Fort Lauderdale to Key Biscayne. My work’s saved clients thousands on tows and rebuilds.

Leave a Reply