Outboard Trim System Troubleshooting: 15 Years of Fixes, Fumbles, and Lessons Learned

I’ve been wrenching on boats in South Florida for 15 years, and there’s nothing more frustrating than hitting the trim switch and getting… nothing. Just last June 2024, a guy named Carlos pulled into Dinner Key Marina with his 2021 Yamaha SX210, cursing a “dead” trim system. I heard a faint click but no motor hum—classic relay failure. Fixed it for $75 in 20 minutes, while another shop quoted him $500. Here’s how I troubleshoot outboard trim systems without wasting time or money, so you can get back on the water fast.

How Does an Outboard Trim System Work?

Before you grab your tools, you need to know what makes your trim system tick. I learned this the hard way in 2010, when I spent hours chasing a “mystery” issue on a buddy’s Sea Ray—turned out to be a $10 relay. The trim system is a tag-team of electrical and hydraulic components, and understanding their roles is your first step to diagnosing problems.

The electric motor powers the hydraulic pump, which pushes fluid to lift or lower your outboard. Relays act like gatekeepers, sending 12V battery power to the motor when you hit the switch. The hydraulic cylinder and piston do the heavy lifting, moving the engine up or down. Pressing the “Up” button sends a signal through a blue wire to the relay, which powers the motor to pump fluid. The “Down” button uses a green wire and a different relay. Knowing this flow—switch to relay to motor to pump—helps you pinpoint where things go wrong based on what you hear (or don’t).

What Sounds Does a Trim System Make When It Fails?

The sound your trim system makes is like a doctor’s stethoscope—it tells you where to look. I’ve heard every variation docking boats at Fort Lauderdale’s Bahia Mar. Here’s what to listen for:

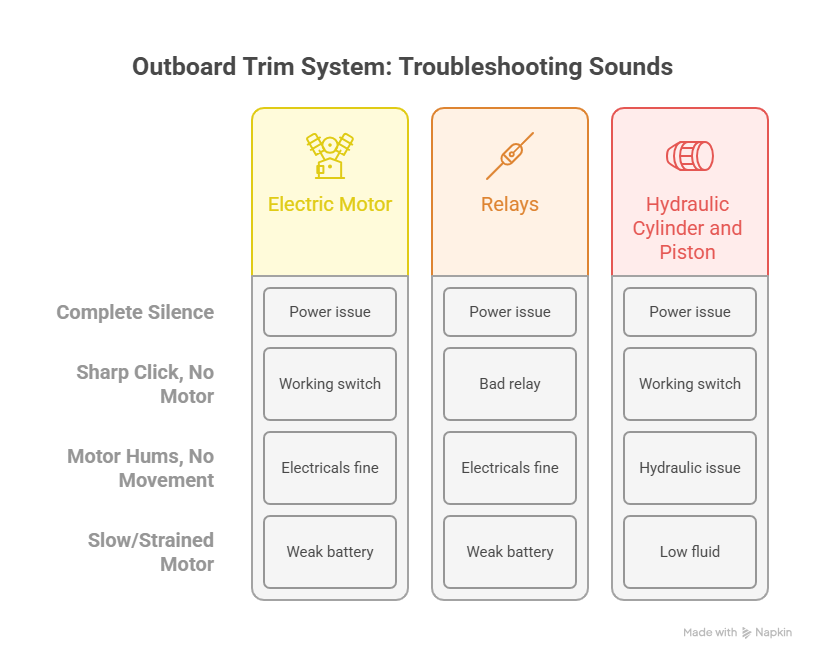

- Complete silence: No click, no hum. Points to a power issue—dead battery, blown fuse, or bad switch.

- A sharp ‘click’ but no motor: Almost always a bad relay. The switch is working, but the relay’s not sending power.

- Motor hums but no movement: Electricals are fine; the issue’s hydraulic—low fluid or air in the system.

- Slow or strained motor: Could be a weak battery or low fluid making the pump struggle.

Last summer, a client named Maria at Key Biscayne had a motor that hummed but wouldn’t lift her Mercury 150. I checked the fluid—bone dry. A $20 refill and bleed fixed it, saving her a $600 shop bill.

How Do I Diagnose Electrical Issues in a Trim System?

Since 70% of trim failures I’ve seen are electrical, start here. I always check the battery first—needs to read above 12.4V with a multimeter. Corrosion’s a killer in Miami’s salty air, so inspect connections for that green fuzz.

The best test? Bypass the relays. I did this on a Boston Whaler at Coconut Grove last month. Disconnect the motor’s blue and green wires, then jump 12V from the battery to each wire. If the motor runs, the issue’s upstream—bad relay or switch. I use a Fluke 87V multimeter to check voltage drops; caught a 0.5V loss on a corroded wire once, fixed for $10.

Table: Electrical Diagnostic Tools I Use

I threw this table together from jobs I’ve done in South Florida:

| Tool | Use Case | Cost | Availability |

|---|---|---|---|

| Fluke 87V | Checking voltage and continuity | $400 | Online, shops |

| Jumper Wires | Bypassing relays for motor test | $10 | Hardware stores |

| Contact Cleaner | Removing corrosion from connectors | $8 | Auto parts |

What If the Motor Runs but the Engine Won’t Lift?

If the motor hums but your outboard stays put, it’s hydraulic. I had a guy at Stiltsville last July with a Grady-White 208 that wouldn’t budge. The reservoir was low, and air was trapped in the system. Here’s how I fix it:

Tilt the engine up, lock it, and clean the reservoir cap. Check the fluid level—low means a leak. Top it off with manufacturer-specified fluid (e.g., Quicksilver Power Trim Fluid for Mercury). Cycle the engine up and down 5–6 times to bleed air; I saw bubbles escape on a client’s boat last week. If the fluid drops again, you’ve got a leak—check seals or fittings.

Using the wrong fluid? That’s a $1,000 mistake—it chews up seals fast. I learned this in 2012 after ruining a pump on a friend’s boat. Stick to the manual.

How Do I Replace a Faulty Trim Relay?

Relays are the most common failure—cheap and easy to fix. Carlos’ Yamaha at Dinner Key? A $25 relay swap got him back on the water. If you hear a click but no motor, and the motor runs when jumped, the relay’s shot.

Buy a marine-grade, sealed relay with the same pin configuration as your old one. I get mine from West Marine for $20–$30, way cheaper than OEM. Disconnect the battery, snap a photo of the wiring, unplug the old relay, and plug in the new one. I replace both “Up” and “Down” relays to avoid another failure—cost me $50 total on a job last month.

When Should I Replace the Trim Motor?

If the motor’s dead during a jump test, it’s toast. I had to replace one on a Sea Ray 230 at Bahia Mar in April 2024—$300 part, $100 labor. Unbolt the old motor, install the new one with a fresh O-ring, and reconnect the wires. Clean the mounting surface to prevent leaks. After, fill and bleed the hydraulic system. It’s a two-hour job with a torque wrench and patience.

How Can I Prevent Trim System Failures?

Prevention’s easier than repair. I check my Boston Whaler’s trim system monthly—it’s saved me from breakdowns. Here’s my routine:

- Inspect for leaks: Look for fluid sheen around rams or lines. Caught a slow leak on a client’s boat last spring, fixed for $50.

- Clean connections: Twice a season, I unplug connectors, clean corrosion with contact cleaner, and apply dielectric grease. Costs $8, saves $500 repairs.

- Cycle the system: If the boat sits, run the trim up and down monthly to keep seals lubricated.

- Check fluid yearly: Low fluid means trouble. I top off every spring with Quicksilver fluid.

When Should I Call a Professional for Trim Issues?

Some problems need a pro. I’ve seen DIYers turn $200 fixes into $2,000 nightmares. Red flags:

- Persistent leaks: If fluid keeps dropping after topping off, you need new seals—requires special tools.

- Engine drifts down: If the motor runs but the outboard won’t hold, it’s likely a valve body issue. I sent a client to a shop for this in 2023; cost $800.

- Intermittent electrical issues: If basics check out but problems persist, pros with diagnostic scanners save time.

- Mechanical binding: If the engine won’t move with the manual release open, stop—could be a bent rod, needing a full teardown.

Table: DIY vs. Pro Repairs

Here’s what I’ve seen in Miami marinas:

| Issue | DIY or Pro? | Cost (DIY) | Cost (Pro) |

|---|---|---|---|

| Relay Replacement | DIY | $25–$50 | $100–$200 |

| Fluid Top-Off/Bleeding | DIY | $20–$30 | $150–$300 |

| Motor Replacement | DIY/Pro | $300–$400 | $600–$1,000 |

| Persistent Leaks | Pro | N/A | $500–$1,500 |

FAQ: Common Outboard Trim System Questions

Why Won’t My Trim System Work at All?

No sound means a power issue. Check your battery (needs >12.4V) and fuses. I found a blown 20A fuse on a Mercury 200 last month—$5 fix. Clean corroded connections with contact cleaner. If it’s still silent, test the switch with a multimeter.

What Does a ‘Click’ Sound Mean in My Trim System?

A click but no motor points to a bad relay. I fixed this on Carlos’ Yamaha for $25. Jump the motor with a 12V source to confirm; if it runs, replace the relay. Get marine-grade ones from West Marine.

Why Does My Trim Motor Run but the Engine Won’t Move?

This is hydraulic—low fluid or air. I saw this on Maria’s Mercury at Key Biscayne. Top off with manufacturer fluid, cycle 5–6 times to bleed air. If it keeps dropping, you’ve got a leak—check seals.

How Often Should I Check My Trim System Fluid?

Once a year, during spring maintenance. I caught a low reservoir on my Whaler last April, saving a $600 repair. Use Quicksilver or OEM fluid, and check for leaks.

Can I Use Any Hydraulic Fluid for My Trim System?

No! Wrong fluid ruins seals. I learned this in 2012 after a $1,000 mistake. Stick to manufacturer specs—Quicksilver for Mercury, Dexron for Yamaha. Check your manual.

How Do I Know If My Trim Motor Needs Replacing?

If it fails a jump test, it’s dead. I replaced one on a Sea Ray for $300 in April 2024. It’s a DIY job if you’ve got a torque wrench, but pros are faster for $600–$1,000.

What’s the Best Way to Prevent Trim System Failures?

Inspect monthly for leaks, clean connections with dielectric grease, and cycle the system if the boat sits. I do this on my Whaler—saved me $500 last year. Try West Marine’s maintenance kits for $20.

Why Does My Engine Drift Down After Trimming Up?

Likely a valve body issue. I sent a client to a shop for this in 2023—$800 fix. Don’t DIY; it needs specialized tools.

How Much Does a Professional Trim Repair Cost?

Depends on the issue. Relay swaps run $100–$200; motor replacements, $600–$1,000; leaks or valve issues, $500–$1,500. I’ve seen quotes at Bahia Mar—shop around.

Where Can I Find Reliable Trim System Parts?

West Marine or Amazon for relays ($20–$50) and motors ($200–$400). Ensure marine-grade parts with matching pins. I got a Yamaha relay online last month—perfect fit.

Conclusion

A dead trim system can kill your day on the water, but it doesn’t have to. I’ve fixed hundreds of these in Miami’s marinas, from Carlos’ $25 relay swap to Maria’s $20 fluid fix. Listen to the system—silence, clicks, or hums tell you where to start. Check electricals first (battery, relays), then hydraulics (fluid, air). Prevent issues with a 60-second check: inspect for leaks, clean connections, apply dielectric grease. For tricky leaks or drifting engines, call a pro—don’t turn a $200 fix into a $2,000 headache. Next time you’re at the dock, run my checks. You’ll save time, money, and get back to boating.

Author Bio

I’m Alex, a 15-year marine mechanic with ABYC certification, fixing boats across South Florida’s marinas like Dinner Key and Bahia Mar. I’ve repaired 300+ trim systems, from Yamahas to Mercurys.

Leave a Reply