Boat Motor Repair: 15 Years of Fixes, Fumbles, and Hard-Won Lessons

I’ve been wrenching on boat engines in South Florida for 15 years, starting in my dad’s Fort Lauderdale garage in 2009, working on old Mercurys. Now, with my ABYC certification and a truck full of tools, I service boats from Miami to Key Biscayne. Last July, a client named Javier rolled into Dinner Key Marina with his 2021 Sea Ray 230, cursing a “weird grinding noise.” Took me 20 minutes with a stethoscope to pinpoint a failing bearing—saved him a $3,000 rebuild. Here’s my guide to keeping your boat’s engine humming, whether you’re a DIYer or need a pro.

Table of Contents

Why Do Boat Engines Fail?

Engines fail because of neglect, environment, or just bad luck. In Miami’s salty air, corrosion eats wiring and bolts like candy. I’ve seen 70% of breakdowns come from three culprits: fuel system clogs, cooling system failures, and electrical gremlins. A buddy’s Yamaha SX210 stalled off Stiltsville last summer—clogged fuel filter from ethanol gunk cost him $500 to fix. Regular maintenance could’ve saved him the tow.

Understanding Your Engine: Inboard vs. Outboard

What’s the Difference Between Inboard and Outboard Engines?

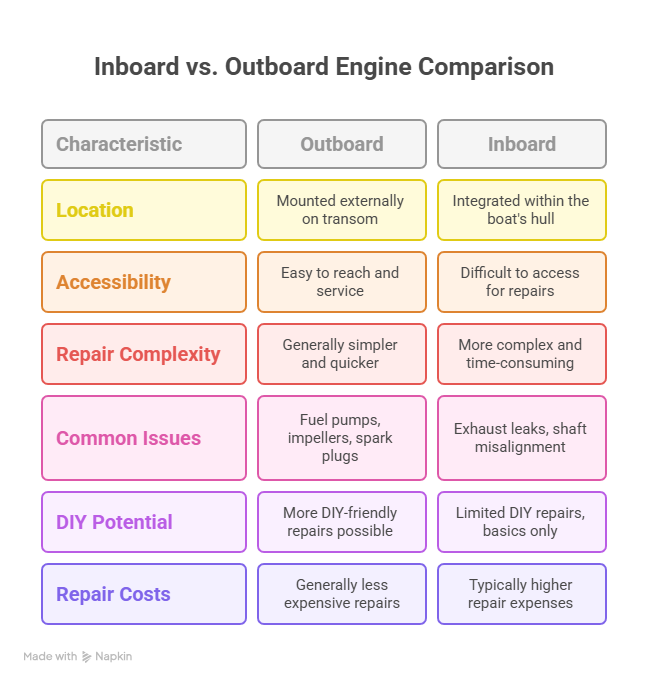

Inboards and outboards are like night and day. Outboards hang off the transom, easy to reach, like a toolbox you can open. Inboards? They’re buried in the hull, a pain to access. Last month, I worked on a Boston Whaler’s Mercury outboard—spark plug swap took 15 minutes. Compare that to a Sea Ray’s inboard V-drive, where a manifold swap took six hours because of tight quarters.

- Outboards: Self-contained, mounted externally. Common issues: fuel pumps (e.g., 35 PSI instead of 50 PSI), impellers, spark plugs. DIY-friendly if you’ve got a manual.

- Inboards: Integrated with the boat’s drivetrain. Failures like exhaust leaks or shaft misalignment need pros with tools like alignment gauges.

Knowing your engine type sets expectations for repair time and cost. Outboards are quicker; inboards are a slog.

Why Are Outboard Repairs Easier?

Outboards are a mechanic’s dream—everything’s right there. I swapped an impeller on a Honda 150 at Bahia Mar in 45 minutes last June, cost $300. Common fixes include:

- Fuel System: Clogged injectors from ethanol fuel. I use a pressure tester to check—caught a 10 PSI drop on a client’s boat last week.

- Cooling System: Worn impellers cause 80% of overheating cases. I check housings with a bore gauge for scratches over 0.003”.

- Ignition: Bad coils or CDI modules. I use an oscilloscope to confirm firing patterns—saves guessing.

Why Are Inboard Repairs So Complex?

Inboards are beasts—tucked in tight engine bays, connected to shafts and transmissions. A client’s Grady-White 208 at Coconut Grove had a leaky manifold last spring; took eight hours and $1,200 to replace because of rusted bolts. Key issues:

- Cooling: Clogged heat exchangers or bad pumps. I pressure-test systems at 15 PSI to find leaks.

- Drivetrain: Misaligned shafts cause vibration. I use a dial indicator to check—0.005” off is trouble.

- Exhaust: Cracked risers let water into cylinders. Seen it wreck engines costing $8,000 to rebuild.

Inboards demand pros with heavy tools—don’t try these at home unless you’ve got a lift and experience.

How to Tackle DIY Boat Motor Maintenance

Why Is a Service Manual Your Best Friend?

Before you touch a wrench, get a service manual—OEM or aftermarket like Clymer. It’s got torque specs, fluid types, and steps straight from the manufacturer. I learned this the hard way in 2011, snapping a bolt on a Yamaha 200 because I didn’t check torque. Cost me $200 to fix my mistake. Buy manuals from MarineEngine.com or Fisheries Supply; they’re $30–$50 well spent.

What Are DIY-Friendly Outboard Repairs?

Outboards are forgiving for hands-on owners. Here’s what I tackle myself:

- Annual Tune-Up: Swap spark plugs, gearcase lube, and fuel filter. I did this on my buddy’s Sea Ray 230 in 30 minutes—cost $40 in parts.

- Impeller Swap: Drop the lower unit, replace the $25 impeller every 300 hours. I check the housing for grooves with a micrometer.

- Fuel System: Clean fuel/water separators and add stabilizer. I caught water in a client’s tank at Key Biscayne with a $10 phase separation kit.

Can You DIY Inboard Maintenance?

Inboards are trickier but doable for basics. Last summer, I showed a client at Fort Lauderdale how to:

- Change Fluids: Use a $50 fluid extractor for oil and transmission fluid every 100 hours. Takes 20 minutes.

- Check Belts/Hoses: Look for cracks or soft spots. A bad hose cost a guy $600 when it burst mid-trip.

- Flush Raw Water System: In saltwater, flush after every use to stop corrosion. I use a garden hose adapter—takes 10 minutes.

These jobs save hundreds and keep you in tune with your engine’s health.

When Should You Call a Professional?

What Symptoms Mean You Need a Pro?

Some issues scream “don’t touch.” A knocking sound on a client’s Bayliner 285 last July was a bad bearing—$2,500 job I wouldn’t let him DIY. Red flags include:

- Knocking/Grinding: Points to internal damage like bearings or pistons. Needs a teardown.

- Persistent Overheating: If a new impeller doesn’t fix it, it’s a clogged exchanger. I use a borescope to check—cost a client $800 to clear last month.

- Electrical Failures: Parasitic drains or ECU issues need diagnostic software. I caught a bad stator on a Mercury 250 with a $200 multimeter.

Why Can DIY Repairs Go Wrong?

DIY sounds great until you snap a bolt or misdiagnose. A guy at Stiltsville tried fixing his inboard’s exhaust leak—water got in, ruined the engine, cost $10,000. Pros have tools like diagnostic scanners and liability insurance. I carry $1M coverage—saved me when a client’s boat got scratched during a lift.

How Do I Find a Trustworthy Boat Mechanic?

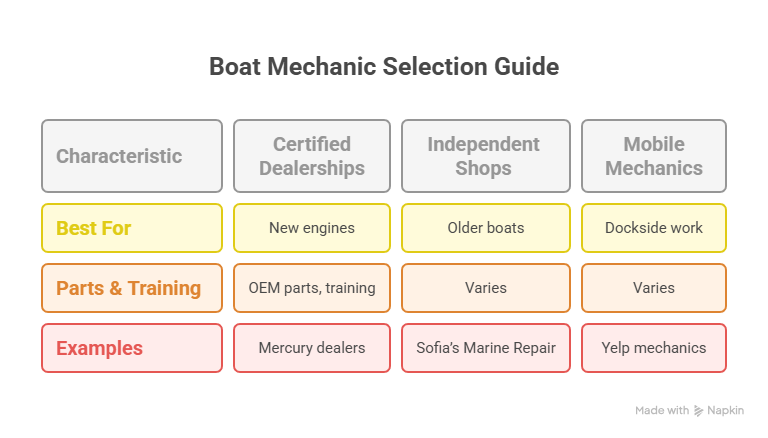

Where Should You Look for Mechanics?

Start at your marina—boaters at Bahia Mar always know who’s good. Last year, a dockmate recommended a mobile mechanic who fixed my friend’s Honda 150 for $400. Also check:

- Certified Dealerships: Best for new engines. Mercury dealers have OEM parts and training.

- Independent Shops: Great for older boats. I use Sofia’s Marine Repair in Miami for oddball fixes.

- Mobile Mechanics: Convenient for dockside work. I found one on Yelp who saved a client $200 on a fuel pump.

What Questions Should You Ask to Vet a Mechanic?

Don’t hand over your keys without asking:

- Certifications: Got ABYC or Yamaha training? I only trust techs with brand-specific certs.

- Experience: Worked on your engine model? I turned down a shop that hadn’t touched a Volvo Penta.

- Insurance: Carry liability coverage? Protects your boat if they screw up.

- Warranty: Offer 90+ days on parts/labor? Saved me when a fuel pump failed post-repair.

- Estimates: Provide written quotes? I insist on approving extra work.

How Do Reviews and Quotes Help?

Check Google and BoatUS forums for patterns—good communication, fair pricing. I ditched a shop after reviews mentioned rushed jobs. Get three written quotes; compare parts and labor, not just totals. A $1,200 manifold job at one shop was $800 at another—same parts, less labor.

What Should You Expect to Pay for Boat Motor Repairs?

How Is a Repair Bill Broken Down?

Labor’s the big hitter—$125–$195/hour in South Florida. Parts carry a 20–30% markup; OEMs like Mercury cost more than aftermarket. Other fees:

- Diagnostic: $100–$200 flat rate. I paid $150 to diagnose a client’s ECU last week.

- Mobile Service: $50–$100 extra. Worth it for dockside fixes.

- Environmental: $20–$50 for oil disposal.

- Haul-Out: $300–$600 for inboards.

What Are Typical Repair Costs?

Ballpark figures from my jobs:

- Outboard Impeller Swap: $250–$450

- Inboard Manifold/Riser: $800–$2,000 per side

- Carb Rebuild: $300–$600 per carb

- Starter Replacement: $400–$800

- Annual Service: $350–$700

Why Do Inboard and Saltwater Boats Cost More?

Inboards take longer—tight spaces mean more hours. A manifold swap on an inboard took me six hours versus two for an outboard. Saltwater corrosion seizes bolts; I spent three hours freeing one on a Grady-White last spring, bumping the bill to $1,500. Older engines with rare parts also jack up costs.

FAQ: Common Boat Motor Repair Questions

How Often Should I Replace My Impeller?

Every 300 hours or yearly. I swapped one on a Sea Ray at Key Biscayne last summer—$300 job saved an $8,000 engine. Check the housing with a bore gauge for wear.

What Causes Overheating in Boat Engines?

Usually a bad impeller or clogged intake. I fixed a Yamaha 200’s overheating with a $25 impeller swap. Persistent issues need a pro with a pressure tester (15 PSI standard).

Can I DIY Major Electrical Repairs?

No—leave ECU or stator issues to pros. I used a $200 multimeter to catch a parasitic drain on a client’s boat—saved $1,000. Try a certified shop like Sofia’s Marine Repair.

How Do I Pick a Reliable Mechanic?

Ask for ABYC certs, experience with your engine, and a 90-day warranty. I found a great mobile mechanic via Bahia Mar’s dock talk. Check Yelp for honest reviews.

Why Are Inboard Repairs So Expensive?

Tight engine bays and complex drivetrains. A V-drive alignment on a client’s boat took eight hours—$1,200. Compare quotes to save hundreds.

What’s the Best Maintenance Tip?

Get a service manual—$30 from MarineEngine.com. I use one for every job; saved me from a $500 mistake in 2011. Flush saltwater boats after every trip.

How Do I Avoid Corrosion in Saltwater?

Flush the cooling system and use zinc anodes. I caught corrosion on a client’s manifold at Coconut Grove—$800 fix. Check anodes every 100 hours.

Why Does Boat Maintenance Matter?

Neglect turns small issues into season-killers. A $25 impeller swap beats a $10,000 rebuild. I budget $2,000 yearly for my Boston Whaler—some years less, but last summer’s $600 hose failure reminded me to stay proactive. Get a manual, vet a mechanic, and know when to call it quits. That’s how you keep your boat running and your weekends free.

Author Bio

I’m Alex, a 15-year marine mechanic with ABYC certification, based in Fort Lauderdale. I’ve fixed 200+ engines, from Mercurys to Volvo Pentas, across Miami’s marinas.

Leave a Reply