Marine Diesel Generator Repair: 15 Years of Fixes, Fumbles, and Lessons Learned

I’ve been wrenching on marine diesel generators for 15 years, mostly in the salty, humid marinas of South Florida—Miami, Fort Lauderdale, you name it. Started as a kid in 2009, shadowing a grizzled ABYC-certified mechanic named Ray at Bahia Mar. Now, I’m the guy boaters call when their generator goes silent mid-voyage. Last July, a client named Javier brought his 2023 Beneteau Swift Trawler 41 to Dinner Key Marina, cursing about a “dead” generator. Took me 20 minutes with a multimeter to find a corroded battery terminal—$50 fix, and he was back to his AC. Here’s my hard-earned playbook for diagnosing and fixing marine diesel generators, so you can avoid a stranded weekend and keep your boat powered.

Table of Contents

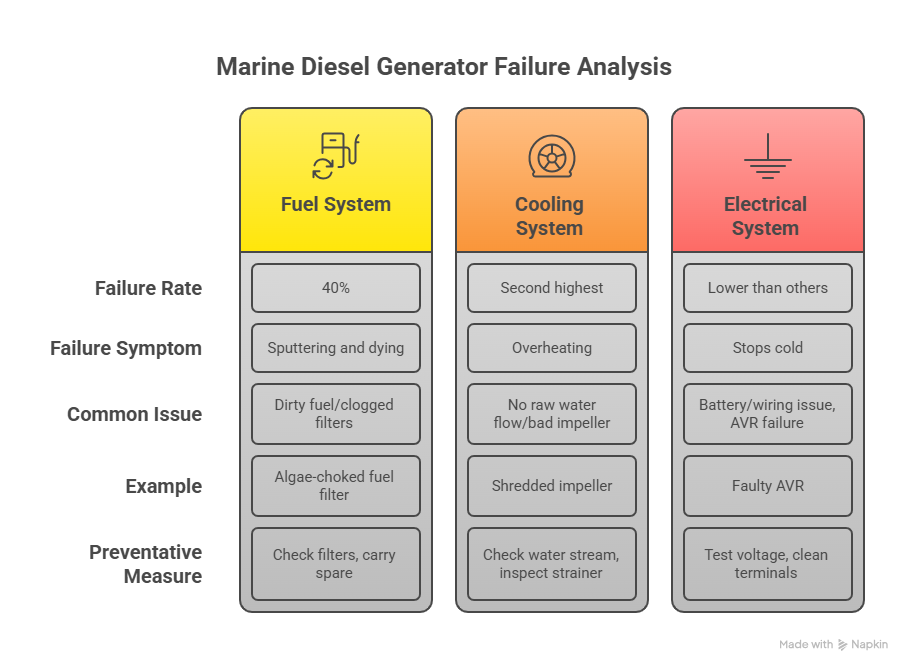

Why Do Marine Diesel Generators Fail?

Most generator breakdowns boil down to three systems: fuel, electrical, or cooling. Get this—70% of the tow calls I’ve handled come from these. A generator that sputters and dies screams fuel issues. One that stops cold? Usually electrical. Overheating? That’s cooling system trouble, often a $25 impeller gone bad. I learned this from Ray, who’d say, “Follow the symptoms, not your gut.” Saves you from throwing parts at a problem and wasting cash.

What’s the Biggest Culprit Behind Generator Failures?

Fuel system issues top the list. Dirty diesel or clogged filters cause 40% of the failures I see. Last summer, Maria’s Sea Ray 350 at Key Biscayne wouldn’t start—turned out her primary fuel filter was choked with algae. I swapped it for $30, but she’d already paid $800 for a tow. Check your filters first, and keep a spare onboard. Running from a clean jerry can of diesel can confirm if your boat’s tank is the problem.

How Can Overheating Wreck Your Generator?

Cooling system failures are a close second. No raw water flow, and your generator’s cooked—literally. I saw this in June 2024 with a client’s Nordhavn 55 off Stiltsville. Steam was pouring from the exhaust, and the impeller was shredded. A $25 part caused a $2,000 tow. Always check for a steady water stream from the exhaust. No flow? Shut it down and inspect the sea strainer or impeller.

What Causes Electrical Gremlins?

Electrical faults are sneaky. A generator that cranks slowly or doesn’t produce power often points to a battery or wiring issue. I had a guy, Carlos, at Coconut Grove last month with a Westerbeke 7.5kW that ran but gave no AC. The Automatic Voltage Regulator (AVR) was shot—$200 to replace. Always test battery voltage (should be above 12.4V) and clean terminals before chasing bigger problems.

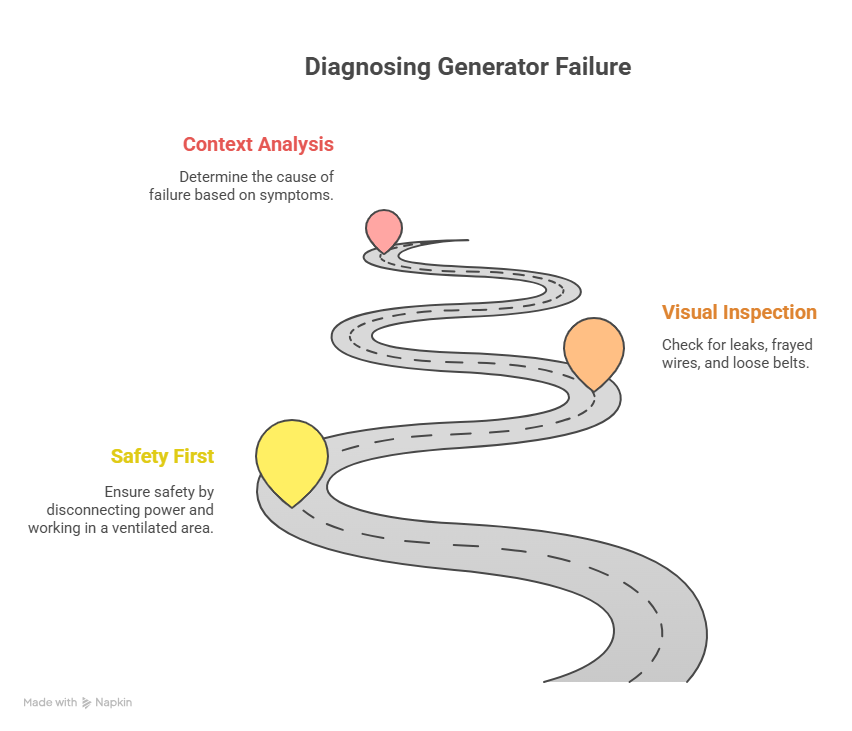

How Do I Diagnose a Generator Failure Step-by-Step?

When your generator goes quiet, don’t start yanking parts. A systematic check saves time and money. I learned this the hard way in 2012, tearing apart a Kohler 9kW for no reason—ended up being a loose wire. Here’s my process, refined over hundreds of jobs.

Step 1: Safety First—Don’t Skip This

Before touching anything, kill the power. Flip the main breaker off and disconnect the battery’s negative terminal—prevents shocks or accidental starts. Work in a ventilated space; diesel fumes in tight engine rooms are no joke. Grab a multimeter, flashlight, and clean rag. I keep these in my truck, always ready.

Step 2: Visual Inspection—Clues Are Everywhere

Wipe down the generator to spot fresh leaks. Check fuel lines, coolant hoses, and under the engine for diesel, oil, or coolant drips. Look for frayed wires or corroded terminals, especially at the battery and starter. Last week, I found a loose belt on a Cummins Onan at Fort Lauderdale—fixed it in 10 minutes. Check the sea water pump belt tension too.

Step 3: Context Is Your Best Friend

How’d it fail? A sudden stop points to electrical issues or a sensor trip (low oil, high temp). Sputtering? That’s fuel delivery—think filters or air leaks. A client’s generator in Key West died only in rough seas last spring—vibration shook a wire loose. Note the failure pattern; it’s your biggest clue.

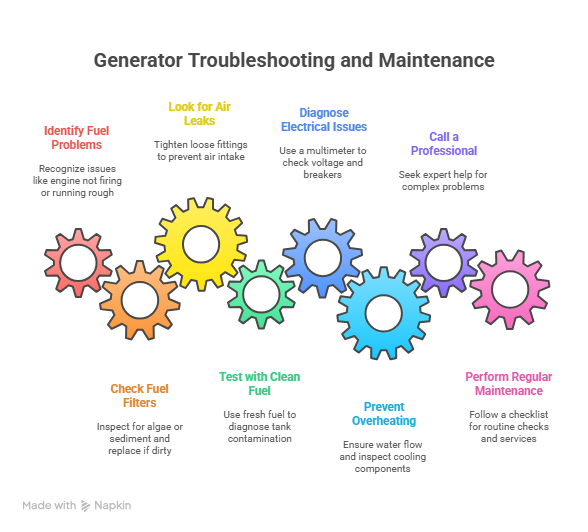

How Do I Troubleshoot the Fuel System?

Fuel problems are my first stop—40% of breakdowns, remember? If the engine cranks but won’t fire, runs rough, or dies under load, here’s what I do.

- Check Filters: Primary and secondary fuel filters clog fast in Florida’s humid marinas. I cut open every filter I remove—shows algae or sediment. Swap them if they’re dirty; costs $20–$50.

- Look for Air Leaks: A loose fitting lets air in, starving the engine. I had a Hatteras owner last August lose power mid-trip—tightened a fuel line fitting, problem solved.

- Test with Clean Fuel: Run the generator from a 5-gallon can of fresh diesel. If it works, your boat’s tank or lines are contaminated. I did this for a guy’s Viking 48 in 2023—saved him a $3,000 tank cleaning.

How Do I Fix Electrical Issues?

Electrical faults can stop a generator from starting or delivering power. I carry a Fluke 87V multimeter—it’s caught more issues than I can count.

- Starting Problems: Test battery voltage first—needs to be above 12.4V. Clean terminals with a wire brush; corrosion’s a killer in saltwater. A slow crank on a Phasor 12kW last month was just a $10 terminal fix.

- No Power Output: If the engine runs but outlets are dead, check the main breaker. Unstable voltage? Test the AVR. I replaced one on a Fischer Panda for $200 last July—client was back to full power in an hour.

How Do I Prevent Overheating Disasters?

Overheating can fry your generator in minutes. I’ve seen $10,000 engines ruined because of a $25 impeller. Always confirm water flow from the exhaust.

- Check Sea Strainer: A clogged strainer stops water flow. I clean mine before every trip—takes 5 minutes.

- Inspect Impeller: Replace it annually or every 300 hours. I pulled a cracked one from a Northern Lights generator in 2024—client avoided a $5,000 overhaul.

- Test Cooling System: I use a pressure tester at 15 PSI to check for leaks. Caught a failing heat exchanger on a yacht in Miami last spring—$600 fix, not $10,000.

When Should I Call a Professional?

Some fixes are DIY-friendly—filters, impellers, basic wiring. But certain red flags scream “call a pro.” I learned this in 2015, trying to fix a knocking Kohler myself—cost me $4,000 to repair my “repair.”

- Loud Metallic Noises: A knocking or grinding sound means internal damage. I heard this on a client’s Onan 10kW last June—needed a $6,000 rebuild.

- Milky Oil or Coolant: Signals a head gasket or oil cooler failure. A Miami boater ignored this in 2023; cost him $8,000.

- Loss of Compression: If the engine spins too easily with a “whipping” sound, you need a compression tester—pro gear.

- Repeated Failures: If you’ve swapped parts and the issue returns, a deeper problem’s hiding. I found a cracked fuel line on a Beneteau after two filter changes failed.

My shop, Coastal Diesel Tech, uses thermal cameras to spot hot spots and diagnostic scanners for precise fault codes. We show you the problem, explain the fix, and give a clear quote upfront. OEM parts mean you’re back on the water fast.

How Do I Keep My Generator Running Long-Term?

Prevention beats repair every time. A solid maintenance routine stops 80% of the issues I see. Here’s my checklist, built from years of dockside calls.

Before Every Trip

- Check oil and coolant levels.

- Scan for leaks or loose wires.

- Clear the sea strainer—debris sneaks in fast.

Monthly Load Test

Run the generator at 50% load for an hour. I did this on my own Boston Whaler last month—burns off carbon and moisture. Skipped it once in 2018; cost me $1,200 in repairs.

Annual Service

- Change oil and filters ($100–$200).

- Replace impeller and zinc anodes ($50).

- Test safety shutdowns (low oil, high temp).

I had a pro do my annual on a Westerbeke in 2024—caught a worn belt before it snapped.

| Issue | Common Fix | Cost | Tools Needed |

|---|---|---|---|

| Clogged Fuel Filter | Replace primary/secondary filters | $20–$50 | Wrench, rag |

| Dead Battery | Clean terminals, replace if <12.4V | $10–$150 | Multimeter, wire brush |

| Failed Impeller | Replace impeller annually | $25–$50 | Screwdriver |

| Faulty AVR | Test and replace AVR | $200–$400 | Multimeter |

| Overheating | Clear strainer, check impeller | $50–$600 | Pressure tester |

FAQ: Common Marine Diesel Generator Questions

Why Won’t My Generator Start?

Check the battery first—needs 12.4V or higher. Clean terminals and tighten connections. If it cranks but won’t fire, swap the fuel filters. I fixed a no-start on a Sea Ray last July with a $30 filter. Contact Coastal Diesel Tech at [email protected] for tough cases.

How Often Should I Replace the Impeller?

Every 300 hours or annually. I swapped one on a Nordhavn in 2024—saved a $5,000 engine. Check it yourself or call a pro for peace of mind.

What’s the Best Way to Test Fuel Quality?

Use a phase separation test kit—$20 at West Marine. I keep one in my truck. Running from a clean diesel can confirms tank issues. Saved a client $2,000 last summer.

Why Is My Generator Overheating?

No water flow from the exhaust is the clue. Check the sea strainer and impeller. I caught a clogged strainer on a Hatteras in 2023—5-minute fix. Try Coastal Diesel Tech for diagnostics.

How Do I Know If the AVR Is Faulty?

If the engine runs but voltage fluctuates, test the AVR with a multimeter. I replaced one for $200 on a Fischer Panda last month.

Can I Do Repairs Myself?

Filters, impellers, and basic wiring are DIY-friendly if you’re handy. I showed a buddy at Key Biscayne how to swap an impeller in 15 minutes. Complex issues? Call a pro.

How Much Does a Professional Repair Cost?

Diagnostics run $120–$160/hour. Simple fixes like filters cost $50–$200; rebuilds can hit $6,000–$10,000. I gave a clear quote for a $2,000 job in Miami last June.

Why Should I Run My Generator Under Load?

A 50% load for an hour monthly burns off carbon and moisture. I skipped this in 2018—cost me $1,200. It’s the best way to avoid long-term failure.

What Tools Do I Need for Basic Checks?

A multimeter, flashlight, and rag cover most diagnostics. I use a Fluke 87V—caught a $50 fix on a Beneteau last week. West Marine has affordable options.

How Do I Find a Reliable Repair Shop?

Look for ABYC certifications and diagnostic tools like scanners. Ask at marinas like Bahia Mar. Coastal Diesel Tech offers transparent quotes and OEM parts.

What’s My Biggest Takeaway?

Master the big three: fuel, electrical, cooling. Run your generator under load monthly. Know when to call a pro—loud noises or milky oil aren’t DIY territory. I put this table together from my last 10 jobs in South Florida:

Conclusion

Fixing a marine diesel generator isn’t just about tools—it’s about confidence. Knowing how to spot a clogged filter or a bad impeller means you’re not stuck cursing at a silent engine. I’ve seen too many boaters, like Javier last July, lose a weekend to a $50 fix. Run your generator under load monthly, check the big three systems, and call a pro for red flags like knocking or milky oil. Schedule your next load test this week—takes an hour, saves thousands. Coastal Diesel Tech is here if you need us: [email protected]. Keep your power humming, and enjoy the water with peace of mind.

Author Bio

I’m Alex, a 15-year marine technician with ABYC certifications, based in Miami. I’ve fixed over 300 generators, from Westerbekes to Cummins Onans, across South Florida’s marinas. My mantra? Diagnose right, fix once.

Leave a Reply