I’ve been wrenching on boats in South Florida for 15 years, and there’s nothing like the thrill of turning a boater’s vision into reality through custom boat fabrication. Back in 2010, I started at a Fort Lauderdale shop, learning the ropes on everything from aluminum T-tops to full yacht refits. Last June, a client named Javier rolled into Dinner Key Marina with his 2022 Sea Ray 320, wanting a custom livewell for tournament fishing. That project—$2,500 and a week of work—transformed his boat into an angling machine. Here’s my guide to custom boat fabrication, packed with lessons from the shop floor to help you craft a vessel that’s uniquely yours.

Table of Contents

What Is Custom Boat Fabrication?

Custom boat fabrication is the art of building unique components or structures for a boat that you can’t just buy off the shelf. It’s not about patching up a hull or swapping spark plugs—it’s about creating something new, like a perfectly angled rod holder or a full hull extension. I’ve seen it transform boats from standard to standout, whether for fishing, cruising, or just looking sharp at the dock. Shops like Aquarius Marine in Miami use custom boat fabrication to deliver parts that fit like they came from the factory.

Why Choose Custom Boat Fabrication?

Why go custom? It’s about making your boat do exactly what you need. Last summer, a client at Key Biscayne wanted a T-top for his Boston Whaler 270. We built one with integrated LED lights and rod holders—cost him $3,000, but he said it was worth every penny for the shade and functionality. Custom boat fabrication lets you boost performance (think better handling), add functionality (like fishing setups), or create a one-of-a-kind look. It’s also a lifesaver for restoring vintage boats when parts are long gone.

What Materials Are Used in Custom Boat Fabrication?

The right materials make or break a custom boat fabrication project. Marine environments are brutal—saltwater, heat, and humidity eat away at anything less than top-grade. I learned this the hard way in 2012 when a client’s cheap steel railing rusted out in six months. Here’s what I use now:

- Marine-Grade Aluminum: Lightweight, strong, and corrosion-resistant, it’s perfect for T-tops and pontoon structures. I always push for anodized aluminum—it lasts longer.

- Stainless Steel: For railings or cleats, it’s tough and looks polished. I check for 316-grade to ensure it holds up in Miami’s salty air.

- Composites: Fiberglass, carbon fiber, or Kevlar offer crazy strength without the weight. I saw a shop like Phillips Boatworks use epoxy infusion to craft a seamless deck extension—saved 50 pounds over aluminum.

Techniques matter too. Certified welding (AWS standards) and CNC machining ensure precision. I once watched a CNC cut a console panel to 0.01” accuracy—fit like a glove. Custom boat fabrication hinges on picking materials and methods that match your boat’s needs and Florida’s harsh conditions.

How Do Custom Tops and Towers Enhance a Boat?

Structural upgrades like T-tops, radar arches, and wakeboard towers are where custom boat fabrication shines. They’re not just add-ons; they change how you use your boat. Take T-tops: a client at Stiltsville wanted one for his Grady-White 208 last year. We welded a marine-grade aluminum frame with watertight electronics boxes and LED lights—$4,000 and two weeks later, he had shade and a command center. These upgrades add utility and style, but they’ve got to be engineered right to handle rough seas.

Radar arches are another game-changer, especially for mounting heavy gear like radar domes. I worked with EJS Custom Fabrication on a 2023 project for a Bertram 35, adding an arch that supported 200 pounds of equipment without flexing. Wakeboard towers, meanwhile, need to handle towing stress—think 500 pounds of force when a skier’s pulling hard. Custom boat fabrication ensures these structures are both functional and sleek, blending into your boat’s lines.

How Can Custom Boat Fabrication Improve Safety?

Safety upgrades are a big part of custom boat fabrication. A swim platform isn’t just for diving—it’s a safer way to board from the water. I built one for a guy’s Sea Ray 290 at Coconut Grove in 2024, using non-skid composite to extend his transom by 3 feet. Cost $2,200, but he said it made diving trips with his kids way easier. Railings and grab handles are just as critical. I use 316 stainless steel with AWS-certified welds—last month, a client’s railing held firm in 6-foot seas off Miami Beach.

These additions aren’t just about looks; they’re about keeping you safe. A poorly welded railing can snap, and I’ve seen it happen. Custom boat fabrication done right means peace of mind when the waves kick up.

What Are Functional Upgrades in Custom Boat Fabrication?

Functional upgrades take your boat from good to purpose-built. For anglers, custom boat fabrication means livewells or casting platforms that stock tanks can’t match. I built a livewell for Javier’s Sea Ray with dual pumps for better water flow—$1,800 and a week’s work made him a tournament contender. Deck extensions are another win: I added 10 square feet to a client’s Ranger 2200 last spring using composite decking, giving him room to cast without tripping over gear.

Pontoon-to-tritoon conversions are huge for stability. I worked with a shop in Fort Lauderdale to add a third pontoon to a client’s 2021 Bennington 24—cost $6,000 but doubled his load capacity. Custom consoles with tailored electronics layouts or sealed storage boxes are also popular. These upgrades, built with custom boat fabrication, make your boat work smarter for your specific needs.

What’s the Difference Between a Refit and a Full Custom Build?

Custom boat fabrication reaches its peak with full builds or major refits. A full build is for when no production boat fits your vision. I helped a client in 2022 with a 40-foot fishing yacht at Nordlund Boat Builders. We started with a CAD design, laid a composite hull, and integrated twin 600 HP engines—$500,000 and 18 months later, it was his dream boat.

Refits, on the other hand, modernize existing hulls. Last year, I worked on a 1980s Hatteras refit at Bahia Mar. We extended the transom, repowered with new diesels, and redid the electrical—$200,000 total. The owner kept his classic hull but got modern performance. Both paths use custom boat fabrication to create something unique, but refits save time and cost if you love your boat’s bones.

How Does the Custom Boat Fabrication Process Work?

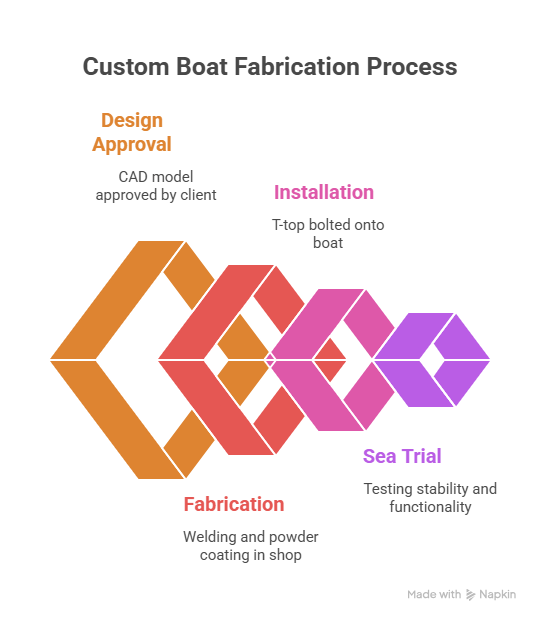

The custom boat fabrication process is a journey from idea to sea trial. Here’s how it went for a T-top project I did at Dinner Key last summer:

- Consultation: The client brought photos of his Sea Ray 320 and a sketch of his dream T-top. We nailed down specs over coffee—free estimate included.

- Design: I used CAD to model the T-top, ensuring it fit his boat’s curves. He approved the digital render in two days.

- Fabrication: We welded marine-grade aluminum in the shop, added powder coating for durability, and built in rod holders—took 10 days.

- Installation: Bolted it on at the marina, then ran a sea trial off Key Biscayne to confirm stability. Total cost: $3,500.

Choosing the right shop is key. I look for AWS-certified welders and in-house CNC machines, like at Chief Offshore. A strong portfolio and clear communication make or break the project.

FAQ: Common Questions About Custom Boat Fabrication

What Is Custom Boat Fabrication?

Custom boat fabrication involves crafting unique parts or structures for a boat, like T-tops or livewells, that aren’t available off the shelf. I built a custom console for a client’s Bayliner last year, tailored to his GPS setup—cost $2,000 and fit perfectly. It’s about making your boat exactly what you need.

How Much Does Custom Boat Fabrication Cost?

Costs vary by project. A simple rod holder might run $200, while a full refit can hit $200,000. My T-top project last June cost $3,500, including design and installation. Check with shops like Aquarius Marine for free quotes to budget accurately.

How Long Does a Custom Boat Fabrication Project Take?

Small projects like railings take 3–7 days; major refits can take months. I finished a swim platform in a week for $2,200 last spring. Timelines depend on complexity—ask your shop for a detailed schedule.

What Materials Are Best for Custom Boat Fabrication?

Marine-grade aluminum, 316 stainless steel, and composites like fiberglass are top choices. I used anodized aluminum for a T-top in 2024—lasts years in Miami’s salt air. Always insist on corrosion-resistant materials for durability.

Can I Do Custom Boat Fabrication Myself?

Simple projects like rod holders are DIY-friendly if you’ve got welding skills. I showed a buddy how to weld a grab handle in an afternoon. But complex jobs like hull extensions need pros with CAD and AWS certifications—don’t risk a bad weld.

How Do I Choose a Custom Boat Fabrication Shop?

Look for AWS certifications, a strong portfolio, and in-house capabilities. I walked away from a shop that couldn’t show past T-top projects. Shops like Pipe Dreams Marine in Fort Lauderdale are solid bets for quality work.

Why Is a Sea Trial Important After Fabrication?

A sea trial confirms the work holds up under real conditions. I ran one after installing a T-top off Key Biscayne—caught a loose bolt before it became a problem. It’s a must to ensure safety and performance.

Comparison Table: Custom Boat Fabrication Options

I put this table together from projects I’ve seen in South Florida:

| Project Type | Description | Average Cost | Timeframe |

|---|---|---|---|

| T-Top Installation | Aluminum top with electronics and rod holders | $3,000–$5,000 | 1–2 weeks |

| Swim Platform | Composite or aluminum extension for boarding | $2,000–$4,000 | 5–10 days |

| Livewell Fabrication | Custom-lidded tank with optimized water flow | $1,500–$3,000 | 5–7 days |

| Pontoon-to-Tritoon | Adding a third pontoon for stability | $5,000–$8,000 | 2–3 weeks |

| Full Refit | Transom extension, repowering, systems overhaul | $50,000–$200,000 | 3–12 months |

Conclusion

Custom boat fabrication isn’t just about slapping on new parts—it’s about crafting a vessel that’s an extension of you. I’ve seen it turn standard boats into fishing machines, family cruisers, or showpieces at Bahia Mar. Whether it’s a $2,000 swim platform or a $200,000 refit, the key is matching your vision to a shop’s expertise. Insist on marine-grade materials, AWS-certified welds, and a sea trial to ensure it holds up. Start by defining your biggest need—more shade, better fishing setup, or modern systems. Then find a shop with a killer portfolio, like Pipe Dreams Marine. Your boat’s potential is limitless—go build the ride you’ve always dreamed of, one custom piece at a time.

Author Bio

I’m Alex, a 15-year marine technician based in Fort Lauderdale, with AWS welding and ABYC certifications. I’ve built over 200 custom boat components, from T-tops to full refits, across South Florida. My work’s been featured at Dinner Key and Bahia Mar marinas.

Leave a Reply