Aluminum Boat Prop Repair – The Dockside Lowdown

I’ve been wrenching on boats down here in South Florida for 15 years, and let me tell you, nothing ruins a day on the water faster than a banged-up prop. Aluminum boat prop repair is one of those jobs that pops up all the time—whether it’s from hitting a sandbar off Key Biscayne or just the usual wear from salty runs in Biscayne Bay. That grinding thud? Yeah, I’ve heard it too many times. But here’s the thing: not every ding means a big bill. If you know when to file it yourself and when to swap it out, you can save a bundle and keep your rig humming. Aluminum boat prop repair isn’t rocket science, but skip the basics, and you’re asking for vibrations that’ll shake your lower unit apart. Let me break it down like I would over coffee at Dinner Key Marina—inspection, quick fixes, reinstall tricks, and that tough call on repair versus replace.

Table of Contents

Getting Real About Prop Damage

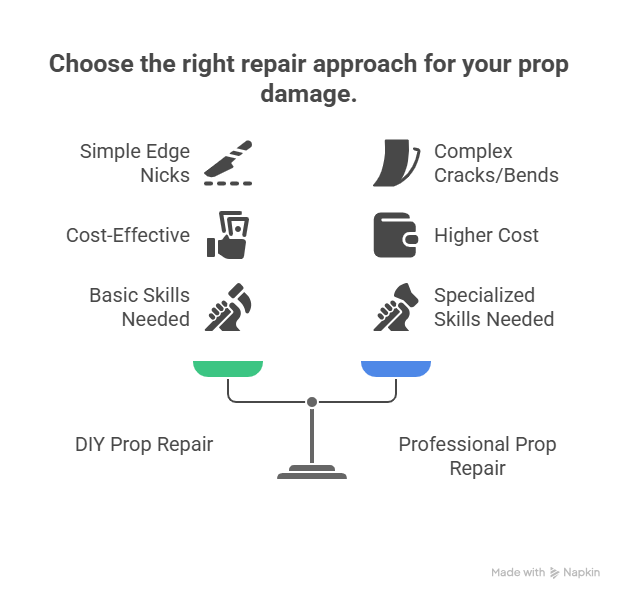

First off, that sickening thump from the stern? It’s a boater’s nightmare. Last summer, a guy named Mike pulled into Bahia Mar with his Sea Ray—prop looked like it tangled with a manatee. Lost power, vibrations everywhere. Aluminum boat prop repair starts with a good look: minor nicks you can handle, but cracks or bends? That’s pro territory. We’ll get into spotting the difference, but remember, it’s not just about looks—it’s protecting your engine from those killer vibes. Drives me nuts when folks ignore it and end up with a seized shaft.

Common Culprits I See Down Here

In Miami’s waters, props take a beating from coral, logs, and just plain salt. Nicks on the edges are the usual suspects—file ’em wrong, and you mess up the balance. Then there’s galvanic corrosion, that white crud building up, especially on aluminum props in our brackish mix. I fixed Sofia’s Boston Whaler last June; her prop was pitted bad from sitting idle at Coconut Grove. Aluminum boat prop repair often boils down to these: edge damage, corrosion, or a spun hub. Weird how the boats change, but the problems don’t.

Quick Inspection Tips from My Toolbox

Grab a flashlight and spin the prop. Look for bends—tap with a mallet for cracks (a ping is good, a thud means trouble). Hang it horizontal to check balance; if it tips, you’re out of whack. I always do this before any aluminum boat prop repair—saved a client’s outboard from vibes that could’ve cracked the housing off Stiltsville.

DIY Fixes for Minor Aluminum Boat Prop Repair

Tackling small dings yourself? Smart move if it’s just edges. I’ve shown buddies how at the marina—keeps costs down. But this is for minor stuff only; big bends need a shop. Aluminum boat prop repair like this is satisfying, but one wrong file stroke, and you’ve got imbalance issues.

Tools You’ll Need – Keep It Simple

No fancy setup required. Coarse metal file for rough work, fine one for smoothing. Emery cloth to polish, a vise with soft jaws (I use an old towel), and gloves—safety first, folks. I carry this kit in my truck for quick jobs at Bahia Mar.

Step-by-Step Filing – Don’t Overdo It

Secure the prop in the vise—stable is key. File from the blade’s back to the leading edge, smooth strokes only. Never hack into the edge; that kills efficiency. I remember filing a Yamaha prop for Ray last fall—nicked from a shallow run in the Keys. Took 20 minutes, balanced perfect. Remove minimal material; it’s aluminum boat prop repair, not reshaping.

The All-Important Balance Check

Hang it from the hub on a pin. Should stay level. If a blade drops? Heavy side—needs pro balancing. Skipped this once early on, and the vibes tore up a lower unit. Non-negotiable in any aluminum boat prop repair.

Post-Repair Care and Reinstall – Lock It Down Right

Fixed? Great. Now protect it and put it back on properly. Half the aluminum boat prop repair calls I get are from bad reinstalls—seized shafts or loose nuts ruining weekends.

Cleaning and Shielding Against Corrosion

Wash off grime with soap and water, dry it good. Slap on marine grease or a prop coating—fights that South Florida salt. Did this for Carla’s Jon boat; her prop stayed clean through a whole season off Key Biscayne.

Reinstall Sequence – Grease and Pin It

Grease the shaft splines thick—prevents seizing, makes next removal easy. Thrust washer first, then prop, spacer if needed, nut torqued to spec. New stainless cotter pin every time—bend those ends secure. Reused one? Asking for the prop to fly off. Learned that the hard way on a mobile job at Dinner Key.

The Big Call: Repair or Replace Your Aluminum Prop?

Not every ding is worth fixing. Aluminum boat prop repair can add up, and sometimes a new one’s smarter. Let’s crunch it like I do for clients.

Cost Breakdown – What I’ve Seen in Miami

Costs vary, but here’s a table I jotted from jobs around Fort Lauderdale—helps decide. Based on real fixes, from DIY to shop work.

| Option | Best For | Average Cost (South Florida) | My Take |

|---|---|---|---|

| DIY Filing | Minor nicks, edges | $20–$50 (tools) | Quick win if balanced—saved me trips. |

| Pro Repair | Bends, small cracks | $100–$300 | Good for salvage, but check the 50% rule. |

| Full Replacement | Spun hubs, major damage | $150–$500 | Fresh balance, no vibes—often the best. |

| Balancing Only | Post-DIY imbalance | $50–$100 | Essential; skipped it once, regretted it. |

When to Just Replace It

Use the 50-60% rule: if repair’s over half a new prop’s cost, buy new. Spun hub? Broken blade? Fatigue cracks? No brainer—replace. Fixed a spun one for Javier at Coconut Grove; cost more than new, and it failed again. Aluminum boat prop repair ain’t worth the risk for big stuff.

Red Flags That Scream “Replace”

Bent blades beyond filing, hubs that spin free, or props with multiple fixes—brittle and unsafe. Seen it off Stiltsville; guy’s prop shredded mid-run. Better a new aluminum prop than a breakdown.

Wrapping It Up – Keep That Prop Spinning Smooth

Aluminum boat prop repair boils down to smart calls: fix minor, replace major, always balance and secure. I’ve botched a few early on—skipped grease, reused pins—but now? Solid habits. Inspect yours today; a little care outlasts the docks at Bahia Mar.

FAQ – Questions I Get at the Marina

Folks hit me up with these all the time—straight answers from 15 years of fixes.

How do I know if my prop needs aluminum boat prop repair?

Vibrations, power loss, visible dings. Hang it to check balance—if it tips, yeah.

Can I file any damage myself?

Minor nicks only. Bends or cracks? Pro shop—don’t risk it in our choppy waters.

What’s the 50% rule in aluminum boat prop repair?

If fixing costs over half a new one’s price, replace. Saved me money on my own rig.

Why a new cotter pin every time?

Old ones fatigue; new stainless keeps it locked. Saw one fail last summer—messy.

How often to check for corrosion in South Florida?

Every few months. Salt eats aluminum fast—grease helps, but inspect regular.

Is balancing really that big a deal?

Absolutely. Imbalance wrecks engines. I balance every aluminum boat prop repair.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified, with 200+ aluminum boat prop repairs under my belt. From minor nicks on outboards to full replacements on sterndrives, I’ve handled them at marinas like Dinner Key and Bahia Mar, keeping props balanced and boats running smooth in our salty conditions.