How to Repair a Fiberglass Boat Deck – A Mechanic’s Real Talk

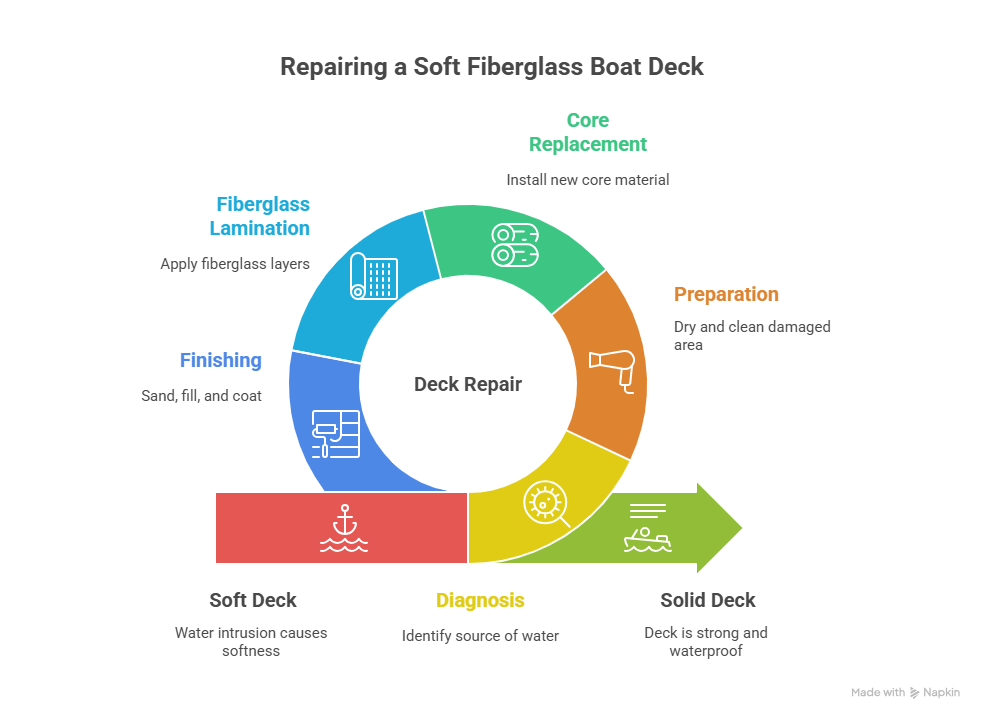

I’ve been wrenching on boats down here in South Florida for over 15 years, and let me tell you, nothing sinks a good day on the water faster than a spongy deck. How to repair a fiberglass boat deck is one of those jobs that scares off a lot of owners, but it’s not as bad as it sounds if you take it slow. That soft spot under your feet? The dull thud when you tap it? Yeah, that’s water sneaking in and rotting the core—classic issue in our humid marinas like Dinner Key. Ignore it, and you’re looking at a full-blown failure, but get it right, and you’ll save a bundle compared to yard prices. I’ll walk you through how to repair a fiberglass boat deck like I do it, with stories from the docks to keep it real. We’ll hit diagnosis, tools, the gritty rebuild, and finishing it off so it looks factory-fresh.

Table of Contents

Why Decks Go Soft and How to Spot the Trouble

Before you even think about mixing resin, you’ve got to play detective on your deck. How to repair a fiberglass boat deck starts with nailing the diagnosis—get this wrong, and you’re patching over problems that’ll come back to bite you. I remember last summer at Bahia Mar, checking out Javier’s Boston Whaler 210—owner thought it was just a crack, but tapping around with a mallet revealed a whole section gone soft from water intrusion. A sharp rap means solid; a thud means trouble. That’s the basics of how to repair a fiberglass boat deck: know what’s hiding underneath.

The Red Flags You Can’t Ignore

Your deck talks if you listen. Grab a plastic mallet and tap away—a crisp sound is good, but that dead thud? Water’s in the core. Look for spongy spots that flex underfoot, hairline cracks around cleats—those are water highways. Delamination shows as bubbles where the fiberglass skin pulls away, and deep gouges let moisture right in. Carla brought her Sea Ray 240 to Coconut Grove last June with what she called “just scratches”—turned out to be full delam, cost her $800 in how to repair a fiberglass boat deck work once we dug in. Don’t skip this; it’s the foundation.

Cored vs. Solid: What You’re Dealing With

Most decks are sandwiches: fiberglass top and bottom with a core like wood or foam in between—light but rot-prone in our salty air. Solid fiberglass won’t rot, but cracks need grinding and layering. Mark your damage with tape, extending 2-3 inches into good material. I learned this fixing Ray’s Grady-White off Stiltsville—skipped the buffer zone once, and water crept back in months later. Accurate mapping is key to how to repair a fiberglass boat deck that lasts.

Gearing Up: Tools and Stuff You Need for How to Repair a Fiberglass Boat Deck

The right kit makes or breaks the job. How to repair a fiberglass boat deck ain’t cheap if you cheap out on materials—use marine-grade or you’ll redo it next season. Precision tools and PPE are non-negotiable; I’ve seen guys skip masks and cough up resin dust for days.

Must-Have Tools That Make It Easier

Oscillating multi-tool for precise cuts, circular saw with diamond blade for big removals, angle grinder for beveling, random orbit sander from 36- to 220-grit. PPE: respirator with vapor cartridges, gloves, goggles—safety first, folks. I put this table together from jobs I’ve done in Miami; it’s rough averages but helps plan.

| Tool/Material | What It’s For | Average Cost | My Tip from Experience |

|---|---|---|---|

| Oscillating Multi-Tool | Precise fiberglass cuts | $100–$200 | Great control—saved me on tight spots at Key Biscayne. |

| Epoxy Resin | Bonding and waterproofing | $50–$150/gal | Always epoxy over polyester; stronger in humidity. |

| New Core (Foam/Plywood) | Replacing rotten sections | $20–$80/sq ft | Foam for rot-proof; used it on a wet Whaler last July. |

| Fiberglass Cloth | Reinforcement layers | $10–$30/yd | Biaxial for strength—holds up better in rough water. |

Picking the Best Materials

Epoxy resin’s my go-to—waterproof and bonds like glue to old polyester. New core: marine plywood for strength, balsa for light weight, or foam to never rot again. Fiberglass: woven for edges, mat for bulk. Stock up right, and how to repair a fiberglass boat deck becomes straightforward.

The Nitty-Gritty: Step-by-Step on How to Repair a Fiberglass Boat Deck

Now we’re into the surgery. How to repair a fiberglass boat deck means getting messy, but patience pays off. Think engineering first, art later.

Cutting Out the Bad Stuff

Set your saw to cut just the top skin—don’t nick the bottom. Perimeter cuts around the marked area, then excavate every crumb of rotten core. Be ruthless; leave any wet bits, and it’s back. Ronnie’s Pursuit at Dinner Key had hidden rot—dug deeper than expected, but it held.

Prepping for a Rock-Solid Bond

Dry it out with fans or heat—bone dry or resin won’t stick. Scarf the edges at 12:1 ratio for max bond area. Acetone wipe to clean. Skipped drying once on a humid day in Fort Lauderdale; patch failed in weeks. Prep is 70% of how to repair a fiberglass boat deck.

Laying In the New Core and Glass

Template the hole, cut core to fit, bed it in thickened epoxy—no voids. Laminate fiberglass layers, wetting each fully till flush. Carlos’s center console off Key Biscayne was a mess; this method made it stronger than new.

Finishing Strong: Making It Look Invisible

Structural’s done; now hide it. How to repair a fiberglass boat deck ends with fairing and coating—patience here turns good into great.

Sanding and Filling for Smoothness

Grind highs with 80-grit, fill lows with fairing compound in thin layers—sand between. Block sand to 220 for seamless feel. It’s tedious, but worth it.

Sealing with Coatings

High-build epoxy primer first, then polyurethane paint (roll and tip) or gelcoat for factory match. Dry weather only—ruined a job in a Miami shower once.

Adding Non-Skid for Grip

Mask, roll base coat, broadcast particles, seal over. Mix-in additives work too. Safety and looks—essential finish for how to repair a fiberglass boat deck.

Wrapping It Up: Lessons from the Marina

How to repair a fiberglass boat deck boils down to diagnose, prep, rebuild, finish—no shortcuts. I’ve botched a few early on by rushing; now I don’t. Inspect often, use quality stuff, and your deck’ll outlast the hull. If it’s over your head, call a pro—but most can handle this with these steps.

FAQ – Dockside Questions I Get All the Time

Boaters hit me with these constantly; here’s my straight answers from years on the water.

How long does a deck repair last?

5-10 years if done right—longer with foam core. Saw one hold 8 years on a salty Sea Ray.

Epoxy or polyester resin?

Epoxy every time—stronger bond in humidity. Polyester’s cheaper but fails faster here.

Can I repair without cutting the top skin?

Sometimes for small spots, but big damage? Cut it out. Tried skipping once; rot spread.

What’s the cost for DIY vs. pro?

DIY: $200-800 in materials. Pro: $1,500+—saved a guy $1k showing him how.

How to prevent future rot?

Seal hardware, check for leaks yearly. Rinse after salt runs—basic but saves repairs.

Is foam core worth the extra?

Yeah, rot-proof—used it on a Whaler that sees Biscayne Bay weekly; no issues.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified, with 200+ fiberglass deck repairs under my belt. From Boston Whalers and Sea Rays to custom fishing rigs, I’ve fixed soft spots, delamination, and rot on them all at marinas like Dinner Key and Bahia Mar, keeping boats solid and safe in our tough saltwater environment.

Leave a Reply