That “Funny Noise” in Biscayne Bay

I got a call last Tuesday. A guy named Javier on a 42′ sailboat out of Dinner Key Marina. “Alex,” he says, “my Yanmar is making a funny noise and blowing black smoke.” I’ve heard that line a hundred times. To a boat owner, it’s a “funny noise.” To me, it’s the sound of money leaving a wallet.

That steady hum of a diesel is the most comforting sound on the water. It’s the heart of your boat. When it hiccups, your whole world can grind to a halt. A real marine diesel engine repair isn’t just about fixing a part; it’s about restoring that confidence to head offshore and know you’ll get back safe.

This isn’t going to be some textbook guide. This is the stuff I’ve learned over 20 years with grease under my fingernails. I’ll walk you through how to listen to your engine, what you can fix yourself, and when you absolutely need to swallow your pride and call a pro. Because when it comes to marine diesel engine repair, a little knowledge can save you from a massive headache.

Table of Contents

When Your Engine Starts ‘Talking’ to You

Diesels are tough, but they aren’t silent sufferers. They give you warnings before they quit. Ignoring them is the fastest way to turn a simple fix into a catastrophic failure. This is the part of marine diesel engine repair that starts with you, the owner.

Here are the classic “tells” I see all the time:

- Black Smoke: This isn’t normal. It’s usually unburnt fuel. Think clogged air filter or a problem with your injectors.

- Engine Overheating: If that temp gauge is climbing, shut it down. You’ve likely got a cooling problem—probably a worn-out raw water impeller or a clogged strainer. This is a five-alarm fire for your engine.

- Weird Noises: Knocking, clunking, grinding… these are screams for help. Something inside is not happy.

- Losing Power: If you’re pushing the throttle forward and not going anywhere, your engine is struggling. Could be fuel delivery, a turbo issue, or a dozen other things.

When you spot something, don’t panic and start pulling things apart. Stop the engine (if it’s serious), take a note of what was happening, check the easy stuff like fluid levels, and then make a call. A good diagnosis is half the battle in any marine diesel engine repair.

The Usual Suspects: What I Fix 90% of the Time

Most of the marine diesel engine repair jobs I do fall into a few categories. These systems take the most abuse in the salty, wet environment of a boat.

Fuel System Headaches

Nine out of ten problems start here. Dirty fuel is the enemy. Water in the tank, algae (the “diesel bug”), debris—it all ends up clogging your filters and starving your engine. Faulty injectors and weak fuel pumps are also common culprits. Clean fuel and fresh filters are your best friends.

Cooling System Nightmares

Your engine’s worst enemy is heat. The cooling system on a boat is a dual-loop beast, and the raw water side is constantly fighting off salt, seaweed, and barnacles. I tell every client: change your raw water impeller annually. It’s a $30 part that can save you from a $15,000 marine diesel engine repair job.

Electrical Gremlins

A diesel doesn’t need much electricity to run, but it needs it to start. Corroded connections, a weak battery, or a failing starter or alternator will leave you stranded at the dock. I spend half my time just cleaning battery terminals and chasing bad grounds.

Just Plain Worn Out

Belts get brittle, hoses crack, engine mounts sag. These are wear-and-tear items. Inspecting them regularly is simple, and replacing them before they fail is a lot cheaper and easier than doing it after they’ve sprayed coolant all over your engine room.

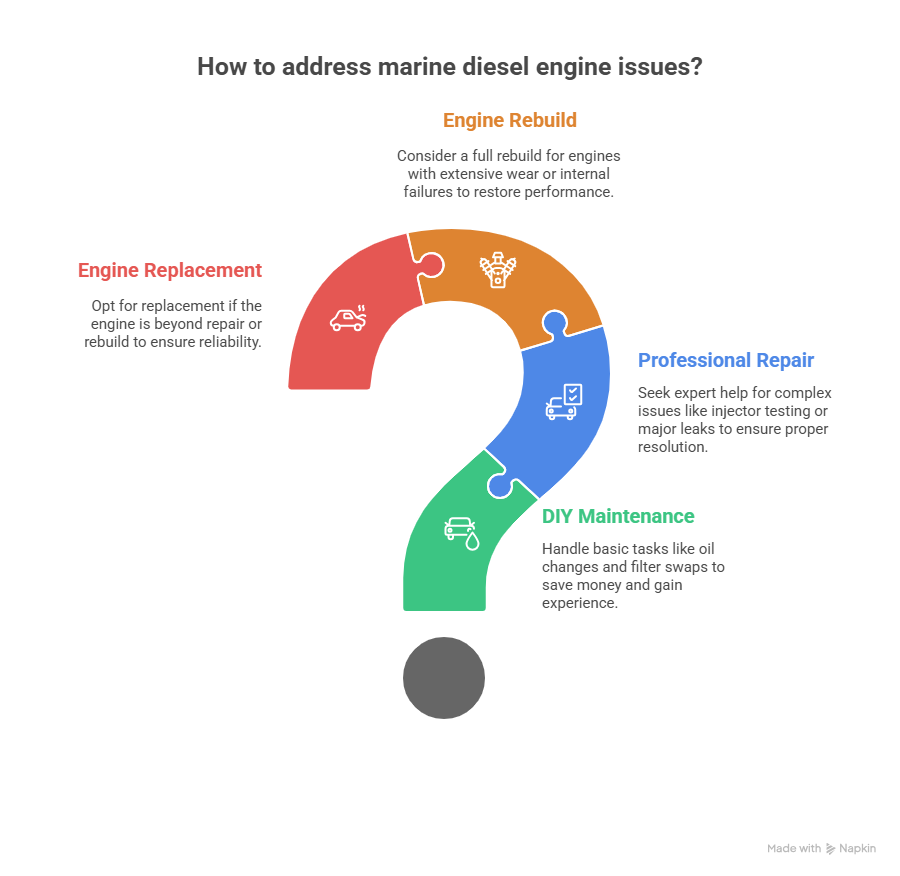

Your Job vs. My Job: A Quick Guide

I believe every boat owner should be able to handle the basics. It saves you money and makes you a better skipper. But you also need to know your limits. Here’s a table I put together to help.

| Task | Your Job (DIY) | My Job (Call a Pro) |

|---|---|---|

| Fluids & Filters | Oil & filter changes, fuel filter swaps, checking coolant. | Flushing the entire cooling system, dealing with major leaks. |

| Fuel System | Bleeding air after a filter change, using fuel additives. | Injector testing and rebuilding, fuel pump replacement. |

| Cooling System | Cleaning sea strainers, replacing the raw water impeller. | Acid-flushing a heat exchanger, diagnosing complex overheat issues. |

| Mechanical | Inspecting belts and hoses, checking engine mounts. | Valve adjustments, compression testing, any internal engine work. |

| Electrical | Cleaning battery terminals, changing a fuse. | Diagnosing charging issues, replacing a starter or alternator. |

Knowing the difference is key to a successful marine diesel engine repair experience.

Beyond a Simple Fix: Talking Overhauls and Rebuilds

Sometimes, a simple repair isn’t enough. When an engine has thousands of hours, low compression, or a major internal failure, we start talking about a rebuild. This isn’t just patching a hole; it’s giving the engine a new lease on life.

I had a guy with an old Bertram whose Cummins engines were tired. He loved the boat, and it had sentimental value. We could have replaced them, but a full rebuild was actually more cost-effective and brought those classic engines back to factory spec. We pull the engine, tear it down to the block, measure everything, replace pistons, bearings, seals—the works. It’s a massive job, and a proper marine diesel engine repair of this scale is a serious investment. But when it’s done right, you’ve basically got a new engine.

The decision to repair, rebuild, or replace comes down to engine age, the extent of the damage, and the value of the boat.

Let’s Talk Money: What a Marine Diesel Engine Repair Really Costs

I won’t lie to you: marine diesel engine repair is expensive. Everything costs more on a boat. Why?

- Access: Engine rooms are cramped, hot, and difficult to work in. Just getting to a bolt can take an hour.

- Specialized Parts: Marine parts are built to withstand corrosion and are often produced in smaller volumes. That means they cost more.

- Expert Labor: You’re not paying for a car mechanic. A certified marine diesel tech has specialized training.

A simple service might run you a few hundred dollars. A starter replacement could be $800-$1,500. A full rebuild? You could be looking at $15,000-$40,000+, depending on the engine. The best way to save money on marine diesel engine repair? Regular maintenance. An ounce of prevention is worth a shipload of cure.

FAQ: Quick Questions I Hear at the Dock

Why is my engine blowing black smoke?

Usually, it’s getting too much fuel or not enough air. Check your air filter first. If that’s clean, you might have an injector problem. Don’t ignore it.

My engine is overheating! What do I do?

Shut it down immediately! Check if you have water coming out of your exhaust. If not, your raw water flow is blocked. The most common culprit is a failed impeller or a clogged sea strainer.

How often should I really change my oil?

Follow the manufacturer’s recommendation, but for most engines, it’s every 100 hours or at least once a year, whichever comes first. Clean oil is cheap insurance.

What’s the most important spare part to have on board?

A spare raw water impeller and the fuel filters for your engine. They are the two things most likely to leave you stranded, and they are relatively easy to change.

Is it worth it to hire a certified mechanic for a simple job?

For an oil change, maybe not. But for diagnostics or any job you’re not 100% confident in, yes. Paying a pro to do it right the first time is cheaper than paying them to fix your mistake. That’s the reality of marine diesel engine repair.

My Bottom Line: Final Thoughts

Look, your diesel engine is the most reliable thing on your boat… until it isn’t. Taking care of it isn’t black magic. If you remember nothing else from this, remember this:

- Listen to Your Engine: Funny noises and strange smoke are warnings. Act on them early.

- Do Your Maintenance: Regular oil changes, filter swaps, and impeller inspections will prevent 90% of the problems I see.

- Know Your Limits: Be honest about what you can handle. There’s no shame in calling a pro. A botched DIY job is a common and expensive start to a major marine diesel engine repair.

- Find a Good Mechanic: Build a relationship with a certified tech you trust before you’re in a panic.

- Safety First, Always: Engines are hot, heavy, and powerful. And diesel fuel is flammable. Always think about safety before you pick up a wrench.

Taking care of your engine gives you the freedom to cast off the lines and head for the horizon with confidence. And that, my friends, is what boating is all about.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified in diesel engines. I’ve rebuilt everything from Yanmars and Volvos to big Cummins engines on sportfishers. You’ll find me working on boats at marinas like Bahia Mar and Dinner Key, keeping them running strong in our tough saltwater environment.

Leave a Reply