“It Just Made a Funny Noise…”

I can’t tell you how many times my phone has rung on a beautiful Saturday afternoon with that exact phrase. It’s usually a frantic owner, stuck somewhere off Key Biscayne with a dead engine and a storm rolling in. And 9 times out of 10, the “funny noise” was something that could have been prevented with about an hour of work and a few bucks in parts the week before.

That’s the honest truth about boats. The engine is the heart. Period. But too many people treat it like a car engine, expecting it to just work until it doesn’t. A marine engine lives a brutal life—saltwater, high loads, long periods of sitting. Ignoring it is asking for trouble.

This is why I’m a stickler about preventive maintenance for marine engines. It’s not about being a master mechanic; it’s about being a smart owner. I had a client, Ray, with a beautiful Sea Ray 320. He skipped changing his impellers. Cost of two impellers? Maybe $100. Cost of his tow back to Miami and fixing the overheated engines? North of $8,000.

This guide is everything I tell my clients. It’s the stuff that keeps you on the water and out of my repair bay. Think of it as cheap insurance against a ruined weekend. A solid program of preventive maintenance for marine engines isn’t a chore; it’s your ticket to confidence at sea.

Table of Contents

The Nitty-Gritty: My Personal PM Checklist

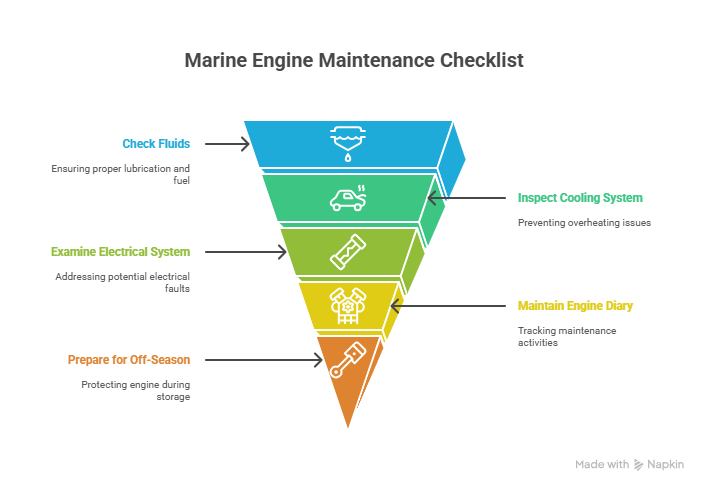

A good checklist is the backbone of any real preventive maintenance for marine engines. This is the list I run through in my head on every boat I service.

Fluids: The Lifeblood of Your Engine

- Oil & Filters: I don’t care what the bottle says—change your oil and filter every 100 hours or once a year, whichever comes first. Clean oil is the single most important part of preventive maintenance for marine engines. Don’t forget the transmission fluid, either.

- Fuel System: Bad fuel is an epidemic in Florida marinas. I saw a brand-new Grady-White get its entire fuel system clogged from one bad tank of gas. Use a biocide, change your fuel filters (both the primary Racor and the on-engine one) every 200 hours, and visually inspect your fuel lines for cracks.

Cooling System: Don’t Get Hot-Headed

Overheating is the #1 killer of marine engines. Saltwater is relentless.

- Impellers: Change them every year or every 300 hours. They are cheap rubber parts that can save you from a catastrophic failure. I cut open every old impeller I replace to check for wear—it tells me a lot about the engine’s health.

- Heat Exchangers & Strainers: Pull and clean your heat exchanger cores and check your sea strainers every single time you go out. A plastic bag sucked into your intake can cook an engine in minutes.

- Hoses and Anodes: Squeeze your coolant hoses. If they feel mushy or crunchy, replace them. And check your zinc anodes; they are designed to sacrifice themselves to save your engine from corrosion. This is crucial for any preventive maintenance for marine engines in a saltwater environment.

Electrical System: Chasing Gremlins

Most “engine problems” I get called for are actually simple electrical issues.

- Batteries: Keep those terminals clean and tight. A little corrosion is all it takes to prevent a start. Make sure your batteries are charging properly and holding voltage.

- Wiring: Look for any chafed or corroded wires. Salt air eats through insulation. A simple visual check can prevent a fire.

To keep my clients on track, I usually give them a simple table like this. Print it, laminate it, and hang it in your engine room.

| Maintenance Task | My Recommended Interval | Alex’s Notes |

|---|---|---|

| Check Engine Oil | Every Trip | Takes 30 seconds. No excuses. |

| Change Oil & Filter | 100 Hours / Annually | This is non-negotiable. |

| Check Sea Strainer | Every Trip | Look for grass, jellyfish, plastic bags. |

| Change Impeller | 300 Hours / Annually | Cheap insurance against a $10k+ bill. |

| Change Fuel Filters | 200 Hours / Annually | Keeps the gunk out. Add biocide to your tank. |

| Inspect Belts/Hoses | Monthly | Squeeze them. Look for cracks or bulges. |

| Check Battery Terminals | Monthly | Keep them clean and tight. Use a wire brush. |

| Change Zinc Anodes | Annually (or when 50% gone) | Crucial for fighting saltwater corrosion. |

Beyond the Basics: Pro-Level Maintenance Habits

Once you’ve got the basics down, a few extra steps can make a huge difference.

Keep an Engine Diary

I tell all my clients to keep a logbook right next to the engine. Write down the date, engine hours, and what you did—even if it’s just a visual check. When you call me with a problem, that log is the first thing I ask for. It helps me spot patterns and diagnose issues way faster. It’s the most underrated tool in preventive maintenance for marine engines.

Off-Season Smarts (Even in Florida)

Even if you don’t “winterize” your boat, it might sit for a few months during hurricane season. Don’t just let it rot. Fill the fuel tank and add a good stabilizer. Change the oil before you store it, so acidic old oil isn’t sitting in the engine. And hook up a battery tender. A little prep saves a lot of headaches come springtime.

What Your Engine is Trying to Tell You (Red Flags)

Your engine will almost always warn you before it has a major meltdown. You just have to know how to listen.

- Smoke Signals:

- Black Smoke: Too much fuel. Usually a dirty air filter or injector issue.

- Blue Smoke: Burning oil. Could be worn piston rings. An expensive problem.

- White Smoke/Steam: Burning coolant or water. Often a head gasket issue or, more commonly, a cooling system failure. Shut it down immediately.

- Weird Noises: Any new clanking, grinding, or high-pitched squealing is a cry for help. Investigate it.

- Vibrations: If the boat starts shaking more than usual, it could be anything from a fouled prop to a misfiring cylinder.

Catching these things early is the essence of smart preventive maintenance for marine engines. Don’t ignore them and hope they go away.

FAQ: Questions I Get Asked at the Dock

How often do I really need to do this stuff?

Follow the 100-hour/annual rule for fluids, and check the simple stuff (strainers, belts) every time you go out. Consistency is what separates a reliable boat from a floating headache.

What’s the one thing people always forget?

The impeller. It’s out of sight, out of mind, until their engine overheats. It’s the most common and most preventable major failure I see. This is why it’s at the top of my list for any preventive maintenance for marine engines.

Can I use automotive parts on my marine engine?

Don’t do it. Marine starters, alternators, and fuel pumps are ignition-protected to prevent sparks from igniting gas fumes in the bilge. Using a car part is a massive fire hazard.

DIY or call a pro like you?

You can and should handle the basics: oil changes, filter swaps, visual inspections. But if you see a weird leak, hear a new noise, or have an intermittent electrical problem, call a professional. Guessing can get very expensive.

What’s more important, hours or age?

Both. An engine with low hours that has sat for five years can have more problems (corrosion, rotten hoses) than an engine with high hours that’s been run and maintained weekly. Time is just as cruel as use.

The Bottom Line

Look, this isn’t about turning you into a certified mechanic overnight. It’s about building confidence and a routine. Good preventive maintenance for marine engines is a habit, not a Herculean task.

By checking the basics, listening to your engine, and keeping a log, you take control. You stop being at the mercy of your machine and start being its partner. You’ll save money, avoid ruined weekends, and most importantly, you’ll be safer on the water. Now go pop the engine hatch and take a look. Your boat will thank you for it.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified in diesel and gasoline engines. I’ve saved hundreds of engines from catastrophic failure through smart preventive maintenance, working on everything from Yamaha outboards to Caterpillar diesels at marinas like Dinner Key and Bahia Mar.

Leave a Reply