Why Did That Cost So Much? A Mechanic’s Guide to Marine Engine Repair Costs

I’ve seen grown men get pale looking at a repair bill. It’s a look I know well here at my shop in Miami. They come in with a sputtering engine, hoping for a quick fix, and leave with an estimate that could fund a small vacation. The first question is always the same: “Why that much?”

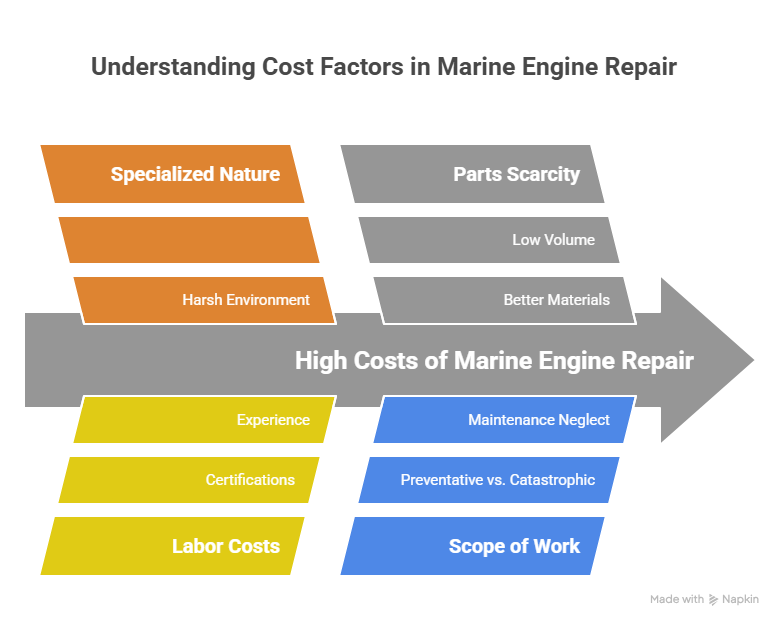

You’re not just paying for a wrench and a new part. You’re paying for expertise in a world that actively tries to destroy machinery. Understanding the core Cost Factors in Marine Engine Repair isn’t just about managing your budget; it’s about understanding your boat.

I remember a guy, Javier, with a beautiful Sea Ray. He ignored a “small ticking noise” for a whole season. That ticking was a valve lifter. By the time he brought it in, that “small tick” had scored a cylinder wall. The repair went from a few hundred bucks to a $6,000 partial rebuild. This is a classic example of how ignoring one of the key Cost Factors in Marine Engine Repair—the extent of damage—can sink your wallet.

So, let’s pull back the curtain. I’m going to walk you through why things cost what they do, from labor rates to the “marine tax” on parts, so you can make smarter decisions and keep your engine—and your finances—afloat.

Table of Contents

It’s a Different Beast: Why Marine Repair Isn’t Like Fixing a Car

First things first: your boat engine lives in a torture chamber. Saltwater, humidity, constant vibration—it’s an environment designed to kill metal. Every single component, from a simple bolt to the engine block itself, has to be tougher, more corrosion-resistant, and built to a higher standard than its automotive cousin. This specialized nature is one of the primary Cost Factors in Marine Engine Repair.

Access is another headache. I can’t just pop the hood. Sometimes I’m crammed into a hot, tight engine room, or we have to haul the whole boat out of the water. If you need a mobile mechanic to come to you at Dinner Key Marina, you’re paying for their travel time before they even pick up a tool. This logistical nightmare is a huge, often overlooked, part of the final bill.

The Labor Bill: Paying for Know-How, Not Just Hours

Let’s talk about that hourly rate. Here in South Florida, you can expect to pay anywhere from $70 to $175 an hour for a good marine mechanic. If you need a certified specialist for a complex diesel engine like a Volvo Penta or a high-performance Mercury, that rate can climb even higher.

Why so much? You’re not just paying for a pair of hands. You’re paying for:

- Certifications: A tech certified by Yamaha or Cummins has spent thousands of hours and dollars on specialized training.

- Experience: An experienced mechanic can diagnose a problem in 30 minutes that a rookie might chase for hours, saving you money in the long run.

- Location & Overhead: A shop on the water in Fort Lauderdale has insane overhead costs compared to a garage inland.

And watch out for the extras. Most reputable shops have a diagnostic fee, which is usually one hour of labor just to find the problem. If you need weekend or after-hours emergency service, expect to pay a premium. Understanding these labor-related Cost Factors in Marine Engine Repair helps you read an estimate without having a heart attack.

The Parts Problem: Scarcity, Salt, and “Marine Tax”

This is what drives people nuts. A water pump for a car might be $80; the marine version could be $400. This isn’t just a random markup; it’s what I call the “marine tax,” and it’s rooted in a few key issues.

- Low Volume: They just don’t make as many marine engine parts as they do for a Ford F-150. Lower production volume means higher cost per part.

- Better Materials: Marine parts use stainless steel, bronze, and specialized alloys to fight corrosion. Those materials cost more.

- Scarcity for Older Engines: Got a 20-year-old sailboat with an old Westerbeke diesel? Good luck. Finding parts can be a treasure hunt, and sometimes we have to get them custom-fabricated. That scarcity is a massive driver among the Cost Factors in Marine Engine Repair.

From a Small Fix to a Major Overhaul: How Damage Dictates the Bill

The scope of the work is, obviously, the biggest factor. A simple, preventative job is always cheaper than a catastrophic failure. I put together this little table based on jobs I’ve done right here in Miami. It gives you a real-world idea of how these Cost Factors in Marine Engine Repair play out.

| Common Marine Engine Repair Job | Typical Cost Range (Miami) | Alex’s Notes |

|---|---|---|

| Impeller & Thermostat Replacement | $250 – $600 | Annual job. Ignore this, and you’re looking at an overheat and a massive bill. |

| Fuel System Service (Filters, etc.) | $300 – $800 | Bad fuel is the #1 killer in Florida. Do this before it clogs your injectors. |

| Starter or Alternator Replacement | $500 – $1,200 | Salt air eats these. A common failure, but straightforward if caught early. |

| Exhaust Manifold/Riser Replacement | $1,500 – $4,500+ | This is a big one. They corrode from the inside out. A leak can destroy an engine. |

| Full Engine Rebuild/Overhaul | $8,000 – $25,000+ | The point of no return. Often happens when smaller problems are ignored for years. |

As you can see, letting a small issue fester is the quickest way to turn a minor expense into a major financial event. Proactive maintenance is your best defense against the high-end Cost Factors in Marine Engine Repair.

The Big Question: Repair Your Old Engine or Repower?

I have this conversation with a boat owner at least once a month. When does it make more sense to stop fixing and just replace the whole engine?

There’s no easy answer, but I tell them to think about it like this: if your repair bill is approaching 30-50% of the cost of a new engine, it’s time to seriously consider a repower. I had a client, Maria, with an older sailboat. The estimate to rebuild her aging diesel was nearly $9,000. A brand new, more efficient engine was about $18,000 installed.

She was throwing good money after bad. For her, the most significant of all the Cost Factors in Marine Engine Repair was the unreliability. She chose to repower. She got a new engine with a warranty, better fuel economy, and peace of mind. Sometimes, the smartest financial move is the one that prevents all future repairs.

How to Keep Costs Down: My Top Advice

You can’t eliminate all Cost Factors in Marine Engine Repair, but you can manage them.

- Be Religious About Maintenance: This is the #1 way to save money. Follow your engine’s service schedule. An oil change is cheap. A new engine is not.

- Find a Mechanic You Trust: Don’t just shop for the lowest hourly rate. A good, honest mechanic will save you money over time with accurate diagnoses and quality work.

- Learn the Basics: Know how to check your oil, your belts, and your fluids. The more you know about your engine’s normal state, the faster you’ll spot a problem.

FAQ: Questions I Get Asked at the Dock All the Time

How much will it cost to just look at my engine?

Most shops charge a one-hour diagnostic fee, so expect to pay whatever their hourly rate is ($70-$175) just for them to identify the problem.

Can I bring my own parts to save money?

Almost never. Most shops, including mine, won’t install customer-supplied parts. It’s a liability issue. If that part fails, who’s responsible? We can’t warranty the work.

Is it cheaper to do repairs in the off-season?

Sometimes, yes. Shops are less busy in the late fall and winter. You might not get a discount on the hourly rate, but you’ll likely get your boat back faster.

Why did my repair take so long?

Often, it’s waiting for parts. Especially for older or less common engines, getting the right components can take days or even weeks, which is another one of those hidden Cost Factors in Marine Engine Repair.

Is a detailed, itemized estimate important?

Absolutely. Never agree to work without one. It should break down the cost of parts and the estimated labor hours. It protects you and the mechanic.

Conclusion: Don’t Let Fear Keep You Dockside

Understanding the Cost Factors in Marine Engine Repair isn’t meant to scare you; it’s meant to empower you. When you know why things cost what they do, you can plan better, maintain smarter, and ask the right questions.

Your engine is the heart of your boat. Treating it with proactive care is the best investment you can make. Don’t wait for a breakdown. Check your maintenance log, find a good mechanic before you need one, and stay ahead of problems. That’s how you control the costs and maximize your priceless time on the water.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified. I’ve dealt with all the Cost Factors in Marine Engine Repair, from simple outboards to complex diesel overhauls. At my shops near Dinner Key and Bahia Mar, I help boaters understand their engines so they can spend less time worrying and more time cruising.

Leave a Reply