That Sinking Feeling When the Engine Goes Quiet

I’ve been wrenching on boats in South Florida for 20 years, and there’s a sound every boater dreads: silence. That sudden, gut-wrenching quiet when your engine coughs, sputters, and dies miles from shore. It happened to a client of mine, a guy named Dave with a beautiful Grady-White, right off of Stiltsville last summer. One minute he was trolling for dolphin, the next his engine was dead quiet. Panic set in.

He called me in a flurry, and we walked through it over the phone. Turned out to be a ridiculously simple fix—a clogged fuel filter he could’ve swapped in 10 minutes if he knew what to look for. That experience is why I believe that troubleshooting common engine failures isn’t just for mechanics; it’s a critical skill for anyone who leaves the dock.

Your marine engine lives a hard life. It’s constantly fighting salt, heat, and vibration. Knowing how to read its warning signs and systematically hunt down the problem can save you a tow, a ton of money, and turn a potential disaster into a minor inconvenience. So, let’s talk about how you can become the first line of defense for your boat’s heart. This isn’t about complex rebuilds; it’s about practical, on-the-water troubleshooting of common engine failures.

Table of Contents

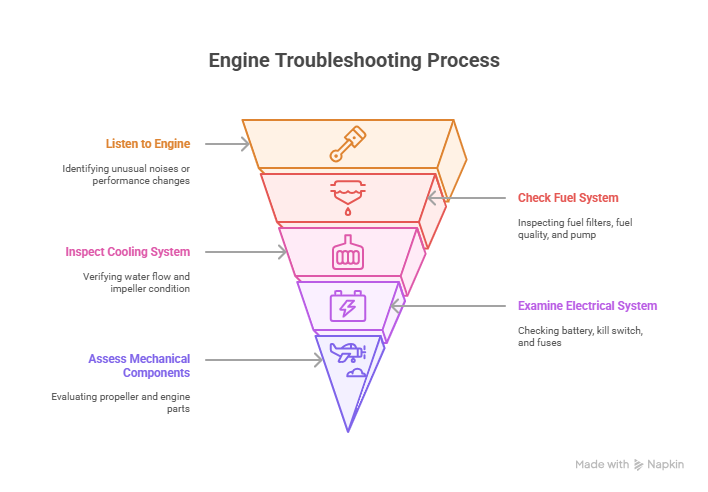

Listening to Your Engine: The First Signs of Trouble

The best tool for troubleshooting common engine failures is your own senses. Engines rarely die without warning. They whisper before they scream.

I tell my clients to pay attention to any changes:

- A new noise? A whine, a clank, a squeal? That’s your engine talking to you.

- Losing power? Is it struggling to get on plane when it used to leap?

- Running hot? Is that temperature gauge creeping up higher than usual?

- Weird smoke? Black, blue, or white smoke from the exhaust tells a story.

A few years back, a customer at Bahia Mar complained his diesel was “just feeling tired.” No alarms, no smoke. We found a small, almost invisible crack in a fuel line that was letting in a tiny bit of air. Catching it then saved him from a high-pressure pump failure that would have cost thousands. Early detection is everything.

The most frequent issues I see fall into four buckets: fuel, cooling, electrical, and mechanical. Mastering the basics of troubleshooting common engine failures in these areas will solve 90% of your problems.

The Diagnostic Detective: Hunting Down the Culprit

When an engine acts up, don’t just start randomly replacing parts. Be a detective. Think methodically. What changed? What does the engine need to run? Air, fuel, and spark (or compression for diesels).

Is It a Fuel Problem? (It Often Is)

This is my first stop in troubleshooting common engine failures. Bad fuel, clogged filters, or a failing pump are the usual suspects.

- Check the Filters: I had a charter captain out of Coconut Grove call me, furious that his brand-new engine was stalling. It was a $5 part: a hopelessly clogged primary fuel filter. Change them religiously.

- Look at the Fuel: Is there water in your fuel/water separator? Does it smell funky? Old ethanol fuel can turn into a gooey mess.

- Test the Pump: Can you hear the fuel pump prime when you turn the key? A simple pressure gauge can tell you if you’re getting enough fuel to the engine.

Is It a Cooling Problem?

Overheating is an engine killer. If your temp alarm goes off, shut it down immediately.

- Check Water Flow: Is water spitting out of the exhaust tell-tale? If not, you have a blockage. I once pulled a plastic bag and a family of barnacles out of a sea strainer.

- The Impeller: This little rubber star is the heart of your cooling system and a primary focus in troubleshooting common engine failures. They wear out. If it’s been more than a year or 100 hours, it’s probably due for a change. A shredded impeller can send rubber bits throughout your engine, causing a massive headache.

Is It an Electrical Gremlin?

Electrical issues are frustrating. They can be intermittent and hard to trace.

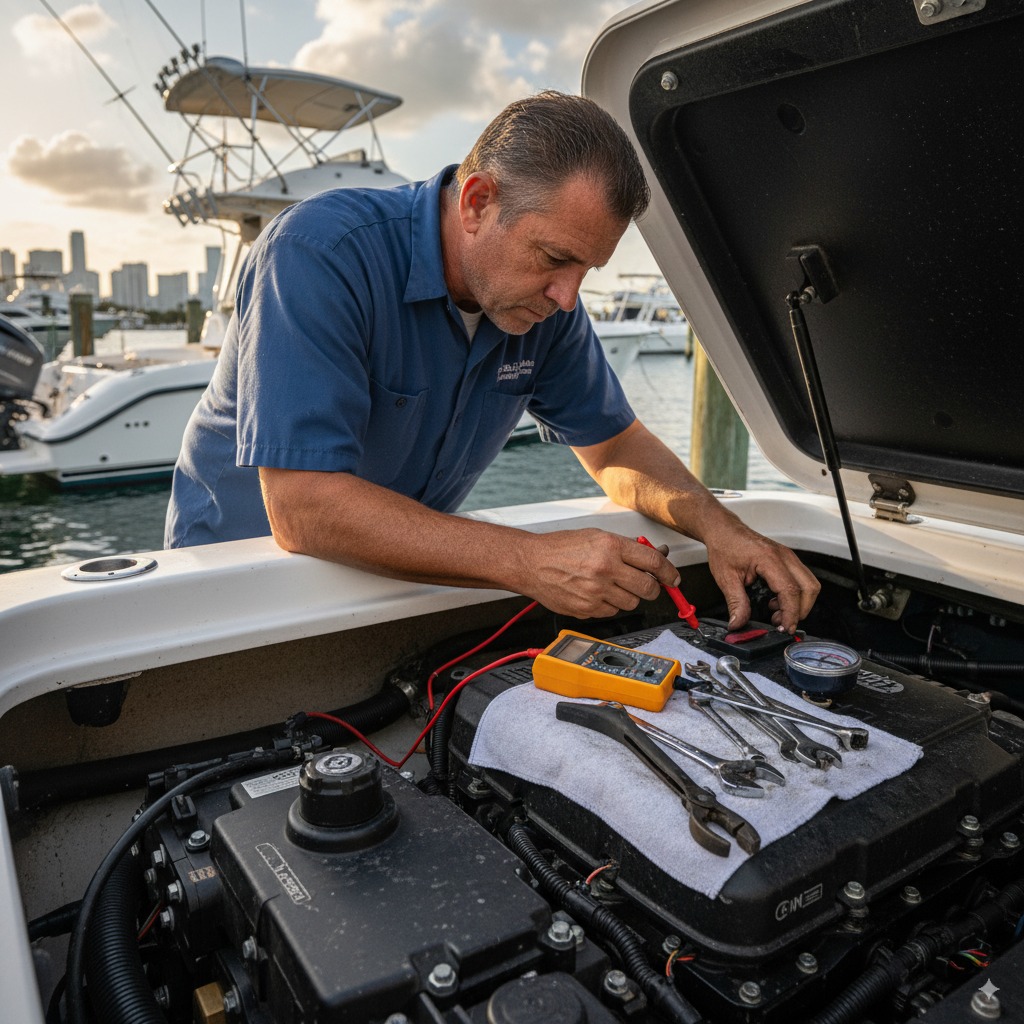

- Start at the Battery: Are the terminals clean and tight? A little corrosion is all it takes to prevent a good connection. I use a simple wire brush and some dielectric grease on every boat I service.

- Check the Kill Switch: Don’t laugh. You have no idea how many “dead engine” calls I’ve had that were solved by re-clipping the safety lanyard.

- Fuses and Breakers: Always check them. It’s a simple step that’s often overlooked in the heat of the moment.

Is It Mechanical?

This category covers everything from the propeller to internal engine parts.

- Look at the Prop: Is it fouled with a rope or a fishing net? A bent or damaged prop will cause vibration and power loss.

- Check the Obvious: Is the engine in neutral? Is the throttle advancing? Sometimes the simplest solutions are the right ones.

Here’s a quick table to help you decide when to tackle it yourself versus calling a pro like me.

| Problem | DIY Fix? | My Notes |

|---|---|---|

| Clogged Fuel Filter | Yes | Easiest fix in the book. Carry spares. |

| Bad Impeller | Yes, with practice | Can be tricky depending on access, but very doable. |

| Dead Battery | Yes | As long as you know how to connect it correctly. |

| Overheating | Maybe | You can check for blockages, but if it’s internal, call for help. |

| Engine Won’t Turn Over | Maybe | Could be a simple electrical issue, or a seized engine. Be careful. |

The Big Question: Repair, Rebuild, or Replace?

Sometimes the problem is more than a simple fix. When you’re facing a major failure, you have three paths. This is a tough part of troubleshooting common engine failures, but an honest assessment is crucial.

- Repair: If it’s an external component (like an alternator or a heat exchanger), a repair is usually the way to go.

- Rebuild: If you have internal damage (like bad rings or bearings) but the engine block is sound, a rebuild can give your engine a new lease on life for about 50-70% of the cost of a new one. It has to be done by a reputable shop, though.

- Replace: If you have a catastrophic failure like a cracked block, or the engine is just old and tired, sometimes a brand-new or remanufactured engine is the smartest investment. You get a warranty and peace of mind.

FAQ: Questions I Hear Every Day at the Marina

What are the three most common engine failures you see?

Fuel, fuel, and fuel. Seriously. Bad gas, clogged filters, and failed pumps account for a huge percentage of the calls I get for troubleshooting common engine failures. After that, it’s overheating from a bad impeller and electrical issues from corrosion.

How often should I really change my impeller?

Don’t stretch it. Once a year or every 100 hours, whichever comes first. For $30 and an hour of your time, it’s the cheapest insurance you can buy against overheating.

Is ethanol fuel really that bad for my engine?

In a marine environment? Yes. It absorbs water, which can lead to phase separation and all sorts of problems. If you can get non-ethanol fuel, use it. If not, use a good stabilizer and don’t let fuel sit in your tank for months.

What’s one tool every boater should have for basic troubleshooting?

A simple multimeter. It lets you check battery voltage, test for continuity, and hunt down those annoying electrical gremlins. Learning to use one is a game-changer for troubleshooting common engine failures.

My engine is smoking. What does the color mean?

A simple rule of thumb: Black smoke means too much fuel (running rich). Blue smoke means it’s burning oil. White smoke (that smells sweet) is usually coolant, which could mean a serious internal problem like a bad head gasket.

Key Takeaways: My Final Advice

Look, your engine is the heart of your boat. Keeping it healthy is the key to having fun and staying safe. If you remember anything from this, remember this:

- Listen to Your Engine: Early detection is everything. Pay attention to new sounds, smells, or performance changes. That’s the first step in troubleshooting common engine failures.

- Be a Detective, Not a Parts-Changer: Start with the simple stuff. Follow a logical path—fuel, cooling, electrical. Don’t just throw money at it.

- Maintenance Isn’t Optional: Regular oil changes, filter swaps, and impeller inspections aren’t just “suggestions.” It’s the work you do at the dock that keeps you from getting stranded at sea.

- Know When to Call for Help: Don’t be a hero. If you’re in over your head, especially with a major mechanical or electrical issue, calling a certified mechanic is the smartest thing you can do.

Mastering the basics of troubleshooting common engine failures will make you a more confident and capable boater. Now, go check your fuel filter.

Author Bio

I’m Alex, a 20-year marine technician in South Florida, ABYC-certified in marine systems and engines. I’ve spent my career troubleshooting common engine failures on everything from small outboards to large inboard diesels at marinas like Dinner Key and Bahia Mar, helping boaters stay safe and reliable on the water.

Leave a Reply