Key Takeaways

Navigating marine engine repair can feel like charting unknown waters, but understanding rebuild costs and strategies is crucial for any boat owner. These essential takeaways will help you make informed decisions, ensuring your vessel stays reliable and your budget stays afloat.

- A marine engine rebuild is a comprehensive restoration that often provides a cost-effective alternative to full replacement, extending your engine’s life for potentially thousands less.

- Expect rebuild costs for typical recreational inboard engines to fall between $4,000 and $12,000, with larger or specialized power plants potentially exceeding $20,000.

- Your rebuild bill breaks down into substantial costs for core parts, expert labor ($75-$150/hr), specialized machine work, and common unexpected discoveries once the engine is disassembled.

- Major cost drivers include your engine type and size, the severity of damage, parts availability (especially for older models), and varying marine mechanic labor rates by region.

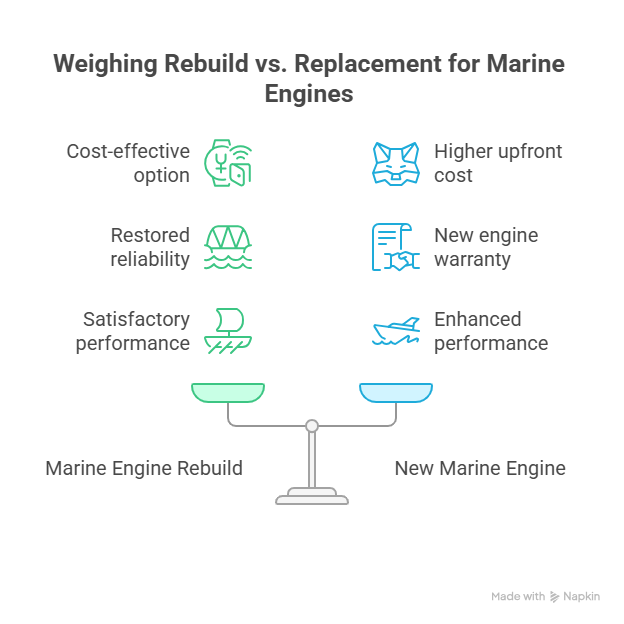

- Make the rebuild vs. replace decision by weighing if the rebuild cost approaches or exceeds 40% of a new, comparable engine’s price, as replacement might then offer better long-term value and warranty.

- Significantly reduce repair expenses by obtaining multiple detailed quotes, strategically performing DIY tasks for less complex work, and above all, prioritizing consistent preventative maintenance.

- Maximize engine longevity post-rebuild by strictly following manufacturer maintenance schedules, regularly maintaining critical fuel, cooling, and electrical systems, and using high-quality components.

Table of Contents

Introduction

That sinking feeling when your marine engine sputters, knocks, or worse—goes completely silent. You immediately wonder: is it dead? And more importantly, what’s this going to cost? For many boat owners, the thought of replacing a marine engine brings on a financial headache that can easily climb to $10,000 or even $30,000+. But what if there was a significantly more cost-effective path to get you back on the water?

Often, a marine engine rebuild isn’t just a viable option; it’s a smart investment that can breathe new life into your vessel without completely draining your budget. It’s about restoring performance and reliability, often for a fraction of the price of a new unit. This guide will demystify the entire process, empowering you with the knowledge to make confident decisions. We’ll dive deep into understanding what a marine engine rebuild actually involves, giving you a clear price breakdown of everything from parts to labor and specialized machine work.

You’ll gain invaluable insights into:

- The typical cost ranges you can expect for different engine types

- How to weigh the crucial decision between rebuilding and replacing

- Smart, actionable strategies to save thousands on your marine engine repair

Ready to get a firm grasp on those repair costs and ensure your vessel enjoys many more reliable seasons on the water? Let’s start by demystifying the marine engine rebuild process itself and understanding what truly goes into it.

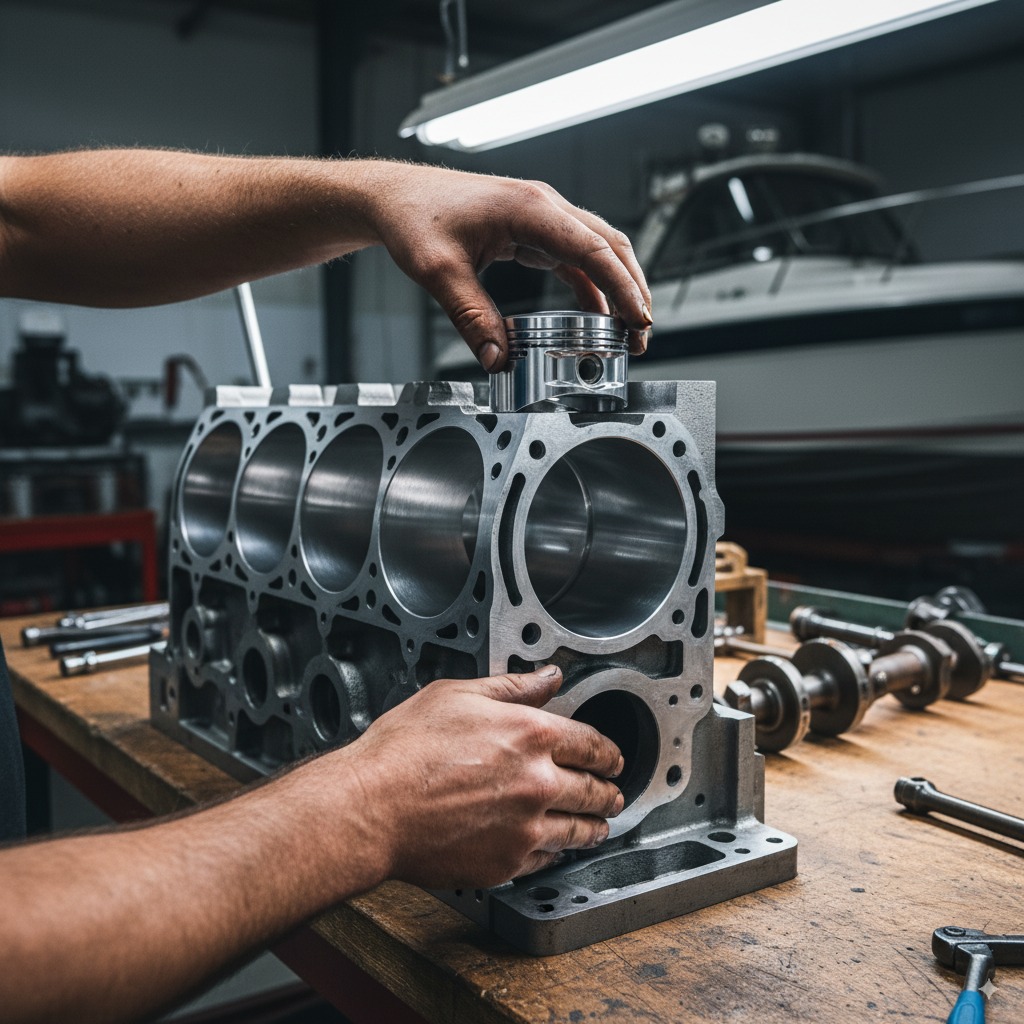

Understanding the Marine Engine Rebuild

A marine engine rebuild breathes new life into a tired power plant, meticulously restoring its core components to near-new condition. This isn’t just a quick fix; it’s a comprehensive process designed for lasting impact. The intensive procedure begins with complete disassembly. Next comes thorough cleaning, detailed inspection of all parts, and precise machining work on the engine block, cylinder heads, and crankshaft.

Addressing Core Issues

Rebuilding aims to address significant internal wear or damage. Think low compression, excessive oil consumption, or that concerning knocking sound – issues far beyond what routine maintenance can remedy. It’s about tackling the root cause of deep-seated problems.

A Smart Investment

For many boat owners, a rebuild represents a cost-effective alternative to full engine replacement. This is especially true for engines with a solid foundation and a history of good maintenance. Choosing to rebuild can save thousands compared to buying new.

How Much Does It Cost to Rebuild a Marine Engine? The Big Picture

When customers ask me, “How much does it cost to rebuild a marine engine?” I tell them it’s like asking the price of a house—it depends on the size, condition, and location. For most inboard engines you see in recreational boats, you’re looking at a ballpark of $4,000 to $12,000. Of course, if we’re talking about a big diesel in a sportfisher, that number can easily sail past $20,000.

Rebuild vs. New Engine: The Cost Divide

Now, compare that to a full replacement. A brand-new engine can set you back anywhere from $10,000 to over $30,000, and that’s before installation. This is why figuring out how much it costs to rebuild a marine engine is so important—it’s often a much smarter financial move. But it’s not just about the upfront cost; it’s a strategic choice about long-term value and reliability.

Cost Snapshot by Engine Type

To give you a clearer picture, here’s a rough breakdown of what I’ve seen in my shop. These numbers really show how size and complexity affect the final bill when you’re estimating how much does it cost to rebuild a marine engine.

| Engine Type | Estimated Rebuild Cost | Notes from My Experience |

|---|---|---|

| Small Outboard (2-5 HP) | $500 – $1,000 | Often not worth it unless it’s a classic. |

| Midsize Outboard (90-115 HP) | $2,500 – $4,500 | Very common; parts are usually easy to get. |

| Inboard (50-100 HP) | $5,000 – $10,000 | The sweet spot for a cost-effective rebuild. |

| Large Inboard (200+ HP) | $10,000 – $20,000+ | Bigger parts, more labor hours, higher costs. |

A good rule of thumb I give my clients: if the answer to “How much does it cost to rebuild a marine engine?” comes back as more than 40% of the price of a new one, you should seriously consider replacement. You get a new warranty and fresh technology, which can be worth the extra cash.

Decoding the Rebuild Bill: Where Your Money Goes

When you get a quote for a rebuild, it’s not just one number. Understanding the breakdown helps you see why the cost is what it is. Here’s how I break it down for my customers.

Parts & Core Components

This is a big chunk of the bill. We’re replacing all the key wear-and-tear items inside the engine.

- Core Internals: Pistons, rings, all the bearings (rod, main, cam), and a full gasket set. These are non-negotiable for a proper rebuild.

- Support Parts: I always factor in a new oil pump and water pump. It’s foolish not to. Depending on the engine, you might need a carburetor rebuild kit or new fuel injectors. This is a crucial part of how much it costs to rebuild a marine engine.

Expert Labor

My time and my team’s time is the next big piece. Marine mechanics typically charge between $75 and $150 per hour. A full rebuild is a meticulous process of disassembly, cleaning, inspection, and reassembly that can take dozens of hours.

Specialized Machine Work

The engine block, heads, and crankshaft almost always need to go to a machine shop. This work is critical and can be up to a quarter of your total bill. It includes:

- Cylinder boring or honing

- Crankshaft grinding and polishing

- Resurfacing the cylinder heads

The “Surprise” Factor

I always tell people to budget for the unexpected. Once we tear an engine down, we often find things like corroded engine mounts, a cracked exhaust manifold, or electrical issues that weren’t obvious before. In the salty marine world, surprises are normal.

Key Factors Driving the Cost

Several things can make the final answer to “How much does it cost to rebuild a marine engine?” swing dramatically.

- Engine Type and Size: A simple 4-cylinder is much cheaper than a complex V8 or a specialized diesel like a Volvo Penta.

- Extent of Damage: A simple wear-and-tear rebuild is one thing. An engine that threw a rod and has a hole in the block is a whole different—and much more expensive—ballgame.

- Parts Availability: For older or less common engines (think vintage Johnsons or Evinrudes), finding parts can be a treasure hunt, and that drives up the cost.

- Your Location: Labor rates vary. A shop in a major coastal city will likely charge more per hour than one in a more rural area.

The Big Decision: Rebuild or Replace?

This is the toughest call for many boat owners. Here’s how I advise them:

When to Rebuild

Rebuilding is a great option if:

- The engine block and major parts are in good shape.

- The rebuild cost is well under that 40% mark of a new engine.

- You’re happy with your current engine’s performance.

- Parts are readily available.

When to Replace

Consider replacement if:

- The rebuild cost is approaching or exceeding the 40% rule.

- There’s major structural damage to the engine.

- You want better performance, fuel efficiency, or new technology.

- Parts for your old engine are hard to find or obsolete.

Smart Ways to Save Money

Even though a rebuild is costly, there are ways to manage the expense.

- Get Multiple Detailed Quotes: Don’t just price shop. Get itemized quotes that break down parts, labor, and machine work. This helps you compare apples to apples.

- Preventative Maintenance: The best way to save money on a rebuild is to not need one in the first place. Regular oil changes, cooling system maintenance, and proper winterization are your best friends.

- DIY Where It Makes Sense: If you’re mechanically inclined, you can save a lot on labor by removing and reinstalling the engine yourself. But I always recommend leaving the internal engine assembly to a professional.

Beyond the Rebuild: Protecting Your Investment

Once your engine is rebuilt, you need to treat it right.

- Follow the Break-In Procedure: I’ll give you specific instructions for the first 20-50 hours. Follow them to the letter.

- Stay on Top of Maintenance: Adhere to the maintenance schedule for oil, filters, and impellers.

- Use Quality Parts and Fluids: Don’t cheap out on oil or filters. It’s a small price to pay for longevity.

- Keep a Log: A detailed maintenance log is not only helpful for you but also adds significant value if you ever sell the boat.

FAQ: Quick Answers from the Shop

How long does a marine engine rebuild take?

It depends on the engine and the machine shop’s schedule, but I usually tell my clients to expect their boat to be out of commission for 3 to 6 weeks.

Will a rebuilt engine be as reliable as a new one?

If it’s done correctly by a reputable shop, absolutely. A professional rebuild restores the engine to factory specs.

Is there a warranty on a rebuild?

Most shops, including mine, offer a warranty. It’s typically for one to two years and covers parts and labor against defects in workmanship.

How much does it cost to rebuild a marine engine myself?

You can save 50% or more on labor, but you’ll need specialized tools, a lot of time, and a deep understanding of engine mechanics. It’s not a project for beginners.

Does a rebuild add value to my boat?

Yes, a well-documented professional rebuild is a major selling point and can significantly increase your boat’s resale value.

Conclusion

Understanding “How much does it cost to rebuild a marine engine?” is about more than just a dollar figure. It’s about making an informed decision that affects your wallet, your time on the water, and your peace of mind. By knowing the factors that drive costs, weighing the rebuild vs. replace options intelligently, and committing to proactive maintenance, you’re not just fixing an engine—you’re investing in your boating future.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified, with hundreds of engine rebuilds under my belt. From simple outboards to complex inboard diesels, I’ve brought them back to life at marinas like Dinner Key and Bahia Mar, helping boaters get back on the water with confidence.

Leave a Reply