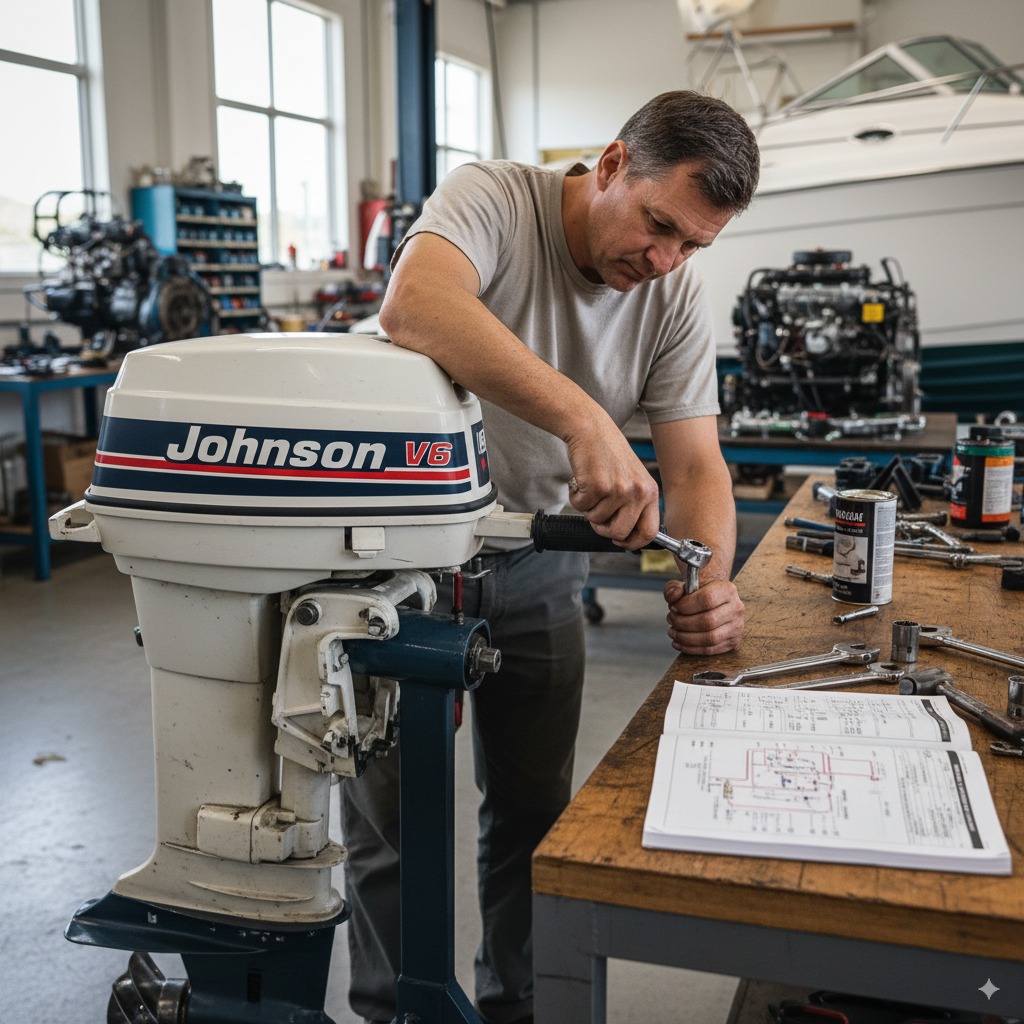

There’s nothing quite like the sound of a Johnson outboard humming along, pushing you across the water. They’re legendary for being tough as nails. But even a legend can have a bad day. I remember a Saturday afternoon, a guy named Ray limped into my shop near Bahia Mar. His trusty Johnson 150 was sputtering and dying every time he tried to get on plane. He was frustrated, ready to throw in the towel on his fishing trip.

He was convinced it was something catastrophic. But instead of just tearing things apart, we went through a simple process—a step-by-step guide to troubleshooting Johnson boat motors that I’ve perfected over 15 years. We checked his fuel, then his spark. Turns out, a tiny crack in a fuel line was letting in air. A ten-dollar part and twenty minutes later, he was back on the water, engine running like a top.

That’s what this is all about. You don’t have to be a master mechanic to figure out these engines. With a little patience and a logical approach, you can solve most common problems yourself. This guide is designed to give you that confidence. We’ll walk through the same diagnostic process I use every day, so you can spend less time guessing and more time boating.

Table of Contents

Getting Started: The Right Mindset and Your Most Important Tool

Before you even think about picking up a wrench, you need to get two things right: your approach and your resources. Johnson motors are straightforward, but you can’t just attack them randomly.

The Golden Rule: One Thing at a Time

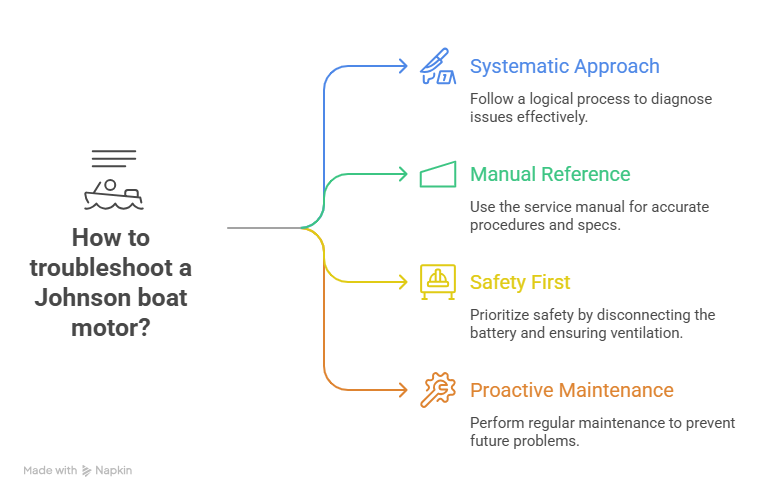

My number one rule is to be systematic. Don’t just start replacing parts. Think like a detective. Is it a fuel problem? An electrical problem? A cooling problem? Isolate one system at a time. This is the absolute core of any effective step-by-step guide to troubleshooting Johnson boat motors. It saves you from wasting money on parts you don’t need and turning a small problem into a big one.

And before you do anything, safety first. Always. Disconnect the battery. Work in a well-ventilated area. Fuel fumes are no joke.

Your Secret Weapon: The Service Manual

Your single most valuable tool is the factory service manual for your specific motor. It’s the bible. It has the diagrams, the specs, the right procedures. You can often find free PDF versions online for older motors, or you can buy aftermarket manuals from Seloc or Clymer, which are great for DIYers. Don’t guess—look it up.

The “Big Three”: Your Diagnostic Roadmap

Almost every issue you’ll encounter comes down to one of three things: fuel, spark, or compression. My whole diagnostic process starts here. If the engine isn’t getting one of these, it won’t run. Period. This is the heart of my step-by-step guide to troubleshooting Johnson boat motors.

- Fuel System: Is the engine getting enough clean fuel? This is the most common culprit. I always start here. Check that the tank vent is open (you’d be surprised how many people forget this). Is the primer bulb firm? Is the fuel old? Old fuel is junk.

- Ignition System: Is the engine getting a strong, consistent spark? Pull a spark plug, connect it to its wire, and ground it against the engine block while a friend cranks the motor. You should see a bright blue spark. No spark, or a weak orange one, means you have an ignition problem.

- Compression: Does the engine have enough compression to fire? This is less common, but critical. A cheap compression tester will tell you if you have a major internal problem.

Common Johnson Problems and How to Fix Them

Here’s a quick-reference table for the issues I see most often in my shop. This is a practical step-by-step guide to troubleshooting Johnson boat motors for everyday problems.

| The Problem | My First Checks | The Likely Fix |

|---|---|---|

| Engine Won’t Start | Fuel, spark, and kill switch. | Clean/replace spark plugs, check fuel filter, ensure kill switch clip is in place. |

| Starts, Then Dies | Fuel tank vent, primer bulb, idle speed. | Open the tank vent, clean the carburetor, check for fuel line leaks. |

| Overheating Alarm | Water stream from the “telltale.” | Replace the water pump impeller. This should be done every 1-2 years anyway. |

| Runs Rough / Misfires | Spark plugs, fuel quality. | Replace old spark plugs, use fresh fuel, check for water in the fuel. |

| Loses Power at High Speed | Clogged fuel filter, weak fuel pump. | Replace the fuel filter, inspect fuel lines, test the fuel pump. |

This simplified step-by-step guide to troubleshooting Johnson boat motors covers about 80% of the issues you’ll ever face.

Proactive Care: Maintenance Hacks to Keep You Running

The best repair is the one you never have to make. A little proactive maintenance goes a long way.

- Change Your Gear Oil Annually: When you drain it, look at the color. If it’s milky, you have water getting in and need to replace the seals. This is a crucial part of any step-by-step guide to troubleshooting Johnson boat motors.

- Use Quality Parts: For things like impellers, thermostats, and fuel pumps, don’t cheap out. Use genuine BRP/OMC parts or high-quality aftermarket brands.

- Build a Small Toolkit: You don’t need a huge toolbox. A good socket set, screwdrivers, a spark plug socket, and a multimeter will handle most jobs.

FAQ: Questions I Get Asked at the Dock

How do I find parts for my really old Johnson motor?

It’s easier than you think. Websites like MarineEngine.com are fantastic. You just need your model number. Many parts were used for decades, so they’re still out there.

Is it worth rebuilding my old Johnson?

If the compression is good and there’s no major corrosion, absolutely. These motors are workhorses. A rebuild can be much cheaper than a new motor and give you many more years of service. A proper step-by-step guide to troubleshooting Johnson boat motors will help you diagnose if a rebuild is necessary.

What’s the biggest mistake DIYers make?

Just throwing parts at a problem without diagnosing it first. They’ll replace the whole ignition system when the real problem was a $5 fuel filter. Follow the step-by-step guide to troubleshooting Johnson boat motors and save your money.

My motor is vibrating a lot. What should I check?

Start with the propeller. Even a small ding or bend can cause a lot of vibration. Also, check to see if you have fishing line wrapped around the prop shaft.

Is professional service for these motors expensive?

It can be, but it’s an investment in reliability. A good mechanic who knows these engines is worth it for complex jobs. For simple tasks, following a good step-by-step guide to troubleshooting Johnson boat motors is your most cost-effective option.

Key Takeaways: My Final Advice

Alright, let’s wrap this up. If you own a Johnson, you own a piece of boating history. Keeping it running is a rewarding experience. Here’s what you need to remember from this step-by-step guide to troubleshooting Johnson boat motors:

- Be Systematic: Don’t guess. Follow a logical process: Fuel, Spark, Compression.

- Your Manual is Your Best Friend: Get the right one and use it. It has the answers.

- Safety First: Always disconnect the battery and work in a safe environment.

- Maintenance Isn’t Optional: It’s the key to reliability. Change your fluids and filters.

- Know Your Limits: Tackle the jobs you’re comfortable with. For anything major, call a pro who knows these engines.

You have the power to keep your Johnson running strong. Start with the simple things. Grab your manual, do a visual inspection, and check your fluids. You’ll be amazed at what you can accomplish. Now get out there and enjoy the water.

Leave a Reply