I’ve been a marine diesel mechanic in South Florida for over 15 years, and I can tell you one thing for sure: the heart of any good boat is a reliable diesel engine. It’s the beast in the engine room that gets you home when the weather turns nasty. But even the toughest engines need some love and understanding.

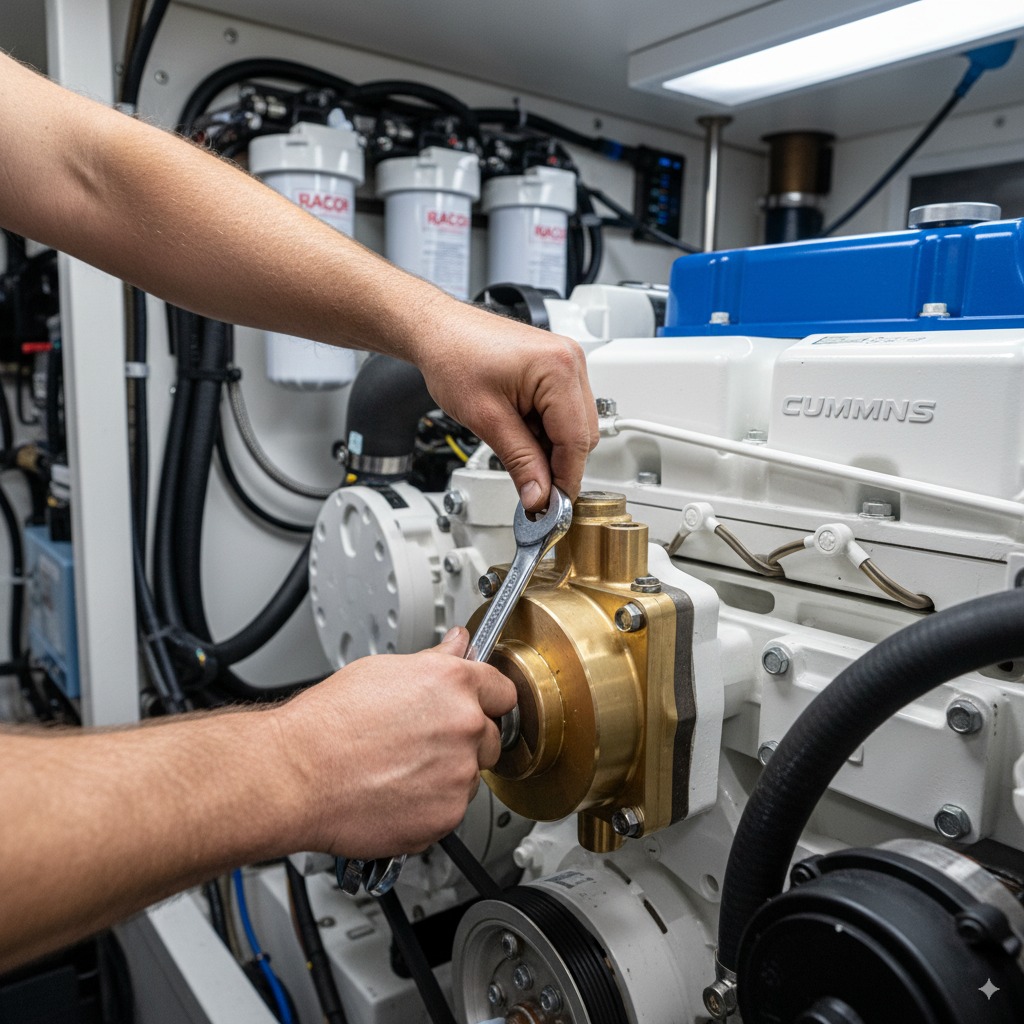

I’ll never forget a guy named Bill who brought his beautiful Grand Banks trawler to me at Bahia Mar. He was frustrated. His engine was blowing black smoke, had no power, and was burning through fuel. He thought he was looking at a major, wallet-busting rebuild. But before tearing anything apart, we did a thorough diagnostic. Turns out, his air filter was completely choked with salt and grime, and one of his injectors was dirty. It wasn’t a catastrophic failure; it was a breathing problem. A few hours of focused marine diesel engine repair and some new filters, and his engine was running clean and strong again.

That’s what this guide is all about. It’s not about complex engineering diagrams; it’s about practical, real-world knowledge. It’s about learning to listen to your engine, knowing what to look for, and having the confidence to tackle problems yourself—or at least know what to tell your mechanic. Let’s dive into the world of marine diesel engine repair.

Table of Contents

Understanding the Beast in Your Bilge

Marine diesel engines are amazing machines. They are overbuilt to be durable, fuel-efficient, and incredibly reliable. Unlike a car engine that loafs along most of the time, a marine diesel is built to run under heavy load for hours on end. That’s why you see them in everything from commercial fishing boats to long-range cruisers.

At their core, they are simple: they need clean fuel, clean air, and good cooling to be happy. But the systems that deliver those things can be complex. Understanding the basics of your fuel system, your cooling system (both raw water and freshwater), and your electrical system is the first step to becoming a confident owner. You don’t need to be an expert in marine diesel engine repair to grasp the fundamentals.

Learning to Listen: What Your Engine is Telling You

Your engine talks to you. You just need to learn its language. Ignoring the early whispers of trouble is the fastest way to end up with a major, expensive problem. I tell all my clients to use the “Listen, Look, and Smell” approach before every trip.

- Listen: Is there a new knock, a high-pitched squeal, or a change in the engine’s rhythm?

- Look: Check for fluid leaks (oil, coolant, fuel), look at the color of the exhaust smoke, and check for loose belts or wires.

- Smell: Do you smell hot oil, burning rubber, or unburnt diesel fuel?

These aren’t just quirks; they are your engine’s early warning system. Catching a small coolant leak early can save you from a catastrophic overheat. A good marine diesel engine repair plan always starts with observation.

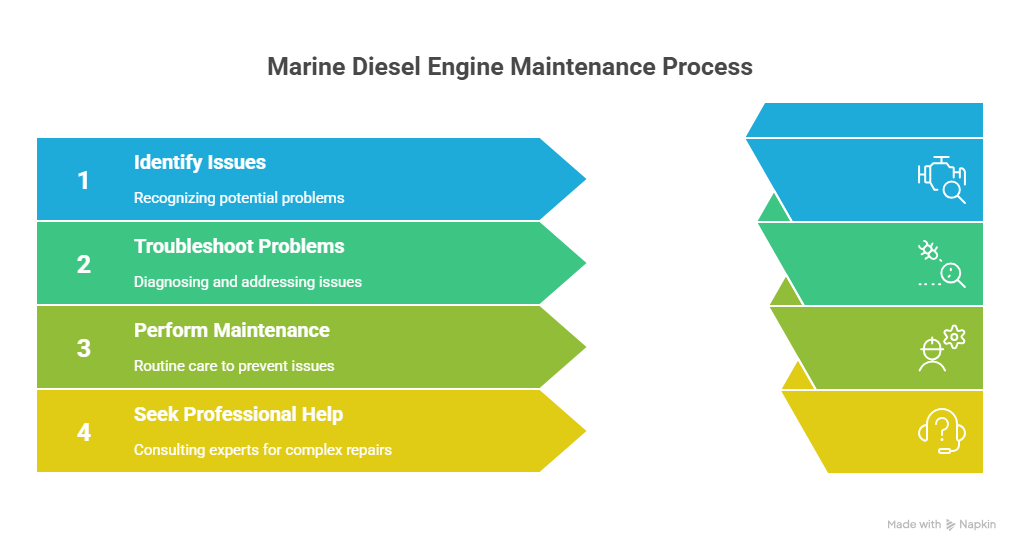

A Detective’s Approach to Troubleshooting

When a problem does pop up, don’t just start replacing parts. Think like a detective. Start with the easy stuff and work your way to the more complex.

Here’s a simple troubleshooting table based on common issues I see. This is the starting point for almost every marine diesel engine repair job that comes into my shop.

| Problem | Listen/Look For | Likely Culprit(s) | My First Steps |

|---|---|---|---|

| Engine Won’t Start | Clicking sound, slow crank | Dead battery, bad connection, air in fuel | Check battery voltage, clean terminals, bleed fuel lines. |

| Overheating | Alarm sounding, steam from exhaust | Clogged sea strainer, bad impeller | Shut down immediately. Check sea strainer for debris. |

| Black Smoke | Engine seems sluggish | Clogged air filter, dirty injectors, overloaded | Check air filter. Are you pushing the engine too hard? |

| White/Blue Smoke | Sweet smell (white), oily smell (blue) | Unburnt fuel, coolant leak, burning oil | White smoke on startup can be normal. Persistent smoke needs a pro. |

| Loss of Power | Can’t reach full RPM | Dirty fuel filters, fouled prop | Change fuel filters first. Check the prop for growth or damage. |

The Big Three Systems

- Fuel System: This is culprit number one, 90% of the time. Clogged filters, water in the fuel, or a weak fuel pump will stop you dead.

- Cooling System: The number one killer of marine diesels. A failed impeller or a clogged heat exchanger can cook your engine in minutes.

- Air System: Your engine needs to breathe. A clogged air filter will suffocate it, leading to black smoke and low power. This is an often-overlooked part of marine diesel engine repair.

Keeping It Healthy: The Boring Stuff That Saves You Thousands

Preventative maintenance is the most important part of owning a diesel. It’s the boring, routine stuff that prevents the exciting (and expensive) breakdowns.

- Stick to the Schedule: Your engine’s manufacturer provides a maintenance schedule for a reason. Follow it. Change your oil, fuel filters, and zincs on time.

- Use the Right Stuff: Don’t cheap out on fluids and filters. Use high-quality oil and genuine or OEM-equivalent parts. This is not the place to save a few bucks.

- Keep a Logbook: This is your engine’s medical chart. Write down every oil change, every filter replacement, every repair. A detailed log is invaluable for troubleshooting and will significantly increase your boat’s resale value. A good log is a key part of any long-term marine diesel engine repair strategy.

FAQ: Questions I Answer Every Day

How often do I really need a professional marine diesel engine repair service?

Follow the manufacturer’s interval, but a major service every 200-250 hours or every two years is a good rule. An oil change should be done more frequently, at least annually or every 100 hours.

What’s the one tool every diesel owner should have?

An infrared (IR) temperature gun. It’s a cheap and amazing diagnostic tool. You can use it to check the temperature of your exhaust manifold, heat exchanger, and alternator to spot problems before they become critical.

Black smoke puffs out when I accelerate. Is that bad?

A little puff of black smoke under heavy load is often normal for older mechanical diesels. It’s called “turbo lag.” But constant black smoke at cruising speed means you have a problem.

My engine is 20 years old. Is it worth doing a major marine diesel engine repair?

Absolutely, if it’s been well-maintained. A 20-year-old, well-cared-for diesel is just getting broken in. These engines are built to last 10,000 hours or more. The cost of a major marine diesel engine repair is almost always less than a repower.

Can I do my own oil changes?

Yes, and you should! It’s a great way to get to know your engine. Just be sure to have a good oil extractor pump and a plan for responsibly disposing of the old oil.

The Bottom Line: What Really Matters

Look, your marine diesel is a reliable partner, but it’s not a set-it-and-forget-it machine. It requires a relationship. If you take care of it, it will take care of you.

- Listen to Your Engine: It will tell you when something is wrong. Don’t ignore it.

- Maintenance is Cheaper Than Repair: An hour of your time and a few bucks in parts can prevent a multi-thousand-dollar failure. Proactive maintenance is the cheapest form of marine diesel engine repair.

- Clean Fuel is Everything: The majority of problems I see are fuel-related. Keep your tanks clean and your filters fresh.

- Don’t Let it Overheat: Overheating is the fastest way to kill a diesel. Keep your cooling system in perfect shape.

- Know When to Call a Pro: Be honest about your skill level. There’s no shame in calling a professional for a complex marine diesel engine repair. It’s a sign of a smart boat owner.

By taking a proactive approach, you’re not just maintaining an engine; you’re investing in your safety, your peace of mind, and your future adventures on the water.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified in marine diesel engine repair. I’ve worked on everything from small Yanmars in sailboats to massive CATs in sportfish yachts. At my shop near Bahia Mar, I help boaters keep their engines reliable, so they can spend more time on the water and less time worrying in the bilge.

Leave a Reply