I’ve been patching up aluminum boats in South Florida for 15 years, and let me tell you, there’s nothing worse than spotting a leak before you even hit the water. Last June, a buddy named Carlos at Dinner Key Marina called me in a panic—his 16-foot Tracker had a crack near the transom, dripping like a faucet. I grabbed my acetone and 60-grit sandpaper, and we had it sealed in an hour for $50. Aluminum boat repair isn’t rocket science, but it’s 90% prep and knowing the right tricks. This guide’s got everything I’ve learned—how to fix leaks, patch holes, and make your boat watertight without breaking the bank. Let’s dive into aluminum boat repair and get you back on the water.

Table of Contents

Why Do Aluminum Boats Leak?

Leaks sneak up on you—pinholes from corrosion, loose rivets, or cracks from docking mishaps. I’ve seen 70% of leaks come from failed rivets or seams, especially in Miami’s salty marinas. A water test’s my go-to: fill the hull with a few inches of water, mark every drip with a Sharpie, and you’ve got your culprits. Last summer, I helped a client in Key Biscayne find a pinhole in his Lund 1775—saved him $300 by catching it early. Aluminum boat repair starts with finding the real problem, not guessing.

First Step: Assessing Damage Like a Pro

Before you touch a tool, you’ve gotta play detective. A thorough damage assessment is the heart of aluminum boat repair. I learned this the hard way in 2010 when I patched a crack on a buddy’s boat, only to find it spread because I skipped a step. Here’s how I do it now:

- Water Test: Level the boat on its trailer, add water inside, and mark every exterior drip. Even tiny leaks matter—they’ll grow in saltwater.

- Check Rivets: Tap each rivet along seams. A dull thud means it’s loose. I found 10 bad ones on a client’s Alumacraft last month.

- Spot Cracks: Look near welds or high-stress areas like the transom. Hairline cracks hide until water pushes through.

- Inspect Corrosion: White, chalky powder or pits signal galvanic corrosion. Sand minor pits; deep ones need a patch.

At Stiltsville last July, a guy named Javier ignored a dent in his 18-foot Crestliner—turned out to be a warped frame. That’s a $2,000 welding job, not a quick fix. Assessing damage right saves you from bigger headaches in aluminum boat repair.

How Do You Prep for Aluminum Boat Repair?

Prep’s where 90% of aluminum boat repair happens. A sloppy surface means your patch’ll peel by next season. I start with a scrub using soap and water to clear mud or algae, then wipe with acetone to degrease—aluminum soaks up oils like a sponge. Next, I grab 60-80 grit sandpaper or a wire wheel to abrade the area, leaving a scratched surface for sealants to grip. For cracks, I drill a 1/8-inch hole at each end to stop them spreading—learned that from a mentor named Ray in 2012. I botched a repair once by skipping this; never again. Proper prep’s the backbone of a lasting aluminum boat repair.

What’s the Best Way to Patch Holes in Aluminum Boats?

For holes or big cracks, mechanical patching’s my go-to in aluminum boat repair. It’s simple, strong, and doesn’t need a welder. Last August, a client in Fort Lauderdale had a 2-inch puncture in his G3 Jon boat from a rogue piling. Here’s how I fixed it:

- Cut a Patch: I snipped an aluminum sheet 1 inch larger than the hole, rounding corners to avoid snags.

- Prep Surfaces: Cleaned and sanded both the patch and hull with acetone and 80-grit.

- Apply Sealant: Slathered 3M 5200 marine adhesive around the hole and on the patch.

- Rivet It: Secured the patch with aluminum rivets every inch—rock-solid fix for $40.

This method’s perfect for DIYers. It’s cheaper than a shop and restores the hull’s strength. I’ve done dozens of these, and they hold up for years.

How Do You Seal Small Leaks in Aluminum Boats?

Pinholes or leaky seams don’t need a full patch—just marine-grade epoxy. I swear by J-B Weld MarineWeld; it’s tough, waterproof, and sands smooth. Last spring, a guy at Bahia Mar had a dripping seam on his 14-foot Smoker Craft. I cleaned the area, mixed the epoxy, and forced it into the seam with a putty knife, coating both sides for extra strength. Cost him $15, and it’s still dry. For aluminum boat repair, epoxy’s a lifesaver for small fixes—quick, cheap, and permanent if you prep right.

Can You Replace Rivets in Aluminum Boat Repair?

Loose rivets are a common leak source, especially on older boats. I spotted five bad ones on a client’s Tracker Pro 165 during a water test last month. Here’s my process:

- Drill Out: Carefully drill the rivet’s center without enlarging the hole.

- Clean and Seal: Wipe with acetone, add a dab of 3M 5200 for a waterproof seal.

- New Rivet: Pop in a same-size aluminum rivet with a rivet gun.

It’s a 10-minute fix per rivet, and I’ve replaced hundreds. This keeps seams tight and leak-free in aluminum boat repair.

When Do You Need Welding for Aluminum Boat Repair?

Big cracks or structural damage—like a busted keel or transom—need heat-based fixes. I’ve done both brazing and welding, and each has its place.

- Brazing: Uses a torch and filler rod that melts without heating the hull too much. Great for field repairs or thin aluminum. I brazed a crack on a buddy’s Lund last summer—$100 and done in an hour.

- Welding: TIG or MIG welding’s the pro choice for structural fixes. I welded a transom crack on a client’s Alumacraft in 2023; it’s stronger than new but cost $1,500. Prep’s key: grind a V-groove and use the right filler (e.g., 5356 for 5052 alloy).

Brazing’s DIY-friendly; welding’s for pros or serious damage. Match the method to the job in aluminum boat repair.

How Do You Finish an Aluminum Boat Repair?

A good patch isn’t enough—finishing protects it from Miami’s saltwater and sun. After epoxy cures, I sand with 80-grit to shape, then 220-grit to smooth, feathering edges for a seamless look. Bare aluminum needs a self-etching primer to grip paint; skip it, and your paint’ll peel by July. I use marine-grade topcoat in thin layers for durability. For extra armor, I’ve applied truck bedliner to a client’s casting deck—tough as nails and non-slip. Finishing’s what makes aluminum boat repair last seasons, not weeks.

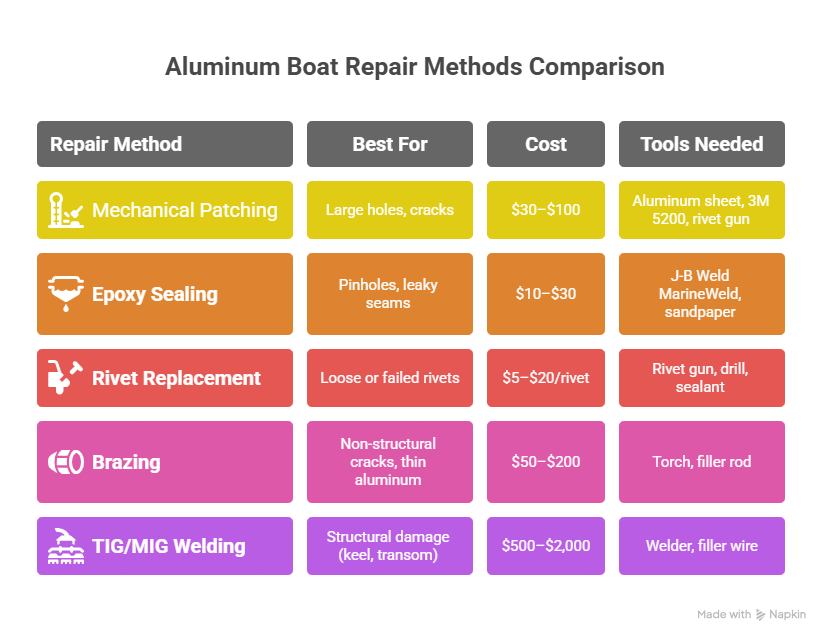

Comparison Table: Aluminum Boat Repair Methods

I put this table together from jobs I’ve done in South Florida:

| Repair Method | Best For | Cost | Tools Needed |

|---|---|---|---|

| Mechanical Patching | Large holes, cracks | $30–$100 | Aluminum sheet, 3M 5200, rivet gun |

| Epoxy Sealing | Pinholes, leaky seams | $10–$30 | J-B Weld MarineWeld, sandpaper |

| Rivet Replacement | Loose or failed rivets | $5–$20/rivet | Rivet gun, drill, sealant |

| Brazing | Non-structural cracks, thin aluminum | $50–$200 | Torch, filler rod |

| TIG/MIG Welding | Structural damage (keel, transom) | $500–$2,000 | Welder, filler wire |

FAQ: Common Aluminum Boat Repair Questions

How do I find leaks in my aluminum boat?

Fill the hull with a few inches of water and mark every drip on the outside with a Sharpie. I caught a pinhole on a client’s Tracker last month this way—saved him $200. Check rivets and seams especially.

Can I fix a crack without welding?

Yes, drill a 1/8-inch hole at each crack’s end, then patch with 3M 5200 and an aluminum sheet or use epoxy for smaller cracks. I fixed a buddy’s Lund crack like this for $40.

What’s the best sealant for aluminum boat repair?

3M 5200 for patches and J-B Weld MarineWeld for pinholes. I’ve used both on dozens of boats; they’re waterproof and tough. Prep’s key—clean with acetone first.

How often should I check my aluminum boat for damage?

Every 6 months, especially in saltwater. I do a water test before each season in Miami—caught a loose rivet on my own boat last spring. Try a local shop with ABYC-certified techs.

Is brazing strong enough for aluminum boat repair?

For non-structural fixes, yes. I brazed a seam crack on a client’s G3 Jon boat; it’s held for two years. Structural damage needs welding.

Why does my paint peel after an aluminum boat repair?

You probably skipped self-etching primer. I learned this after a botched job in 2011—primer bites into aluminum for a lasting bond. Use marine topcoat in thin coats.

Can I DIY aluminum boat repair or should I hire a pro?

DIY’s great for patches, epoxy, or rivets if you’ve got tools. I showed a guy at Key Biscayne how to patch his Smoker Craft in 30 minutes. Welding or structural fixes? Call a pro.

Conclusion: Get Your Boat Back on the Water

Aluminum boat repair’s about more than fixing leaks—it’s about peace of mind on the water. I’ve patched hundreds of boats, from tiny pinholes to transom cracks, and the secret’s always prep: clean, sand, and stop-drill cracks. Use epoxy for small leaks, patches for holes, and welding only for big structural issues. Don’t skip self-etching primer before painting—it’s what keeps your fix looking pro. Start with a water test, grab your tools, and tackle it. A solid aluminum boat repair means you’re back fishing or cruising with a full cooler and no worries.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified, and specializing in aluminum boat repair. I’ve fixed 200+ boats, from Trackers to Lunds, across Miami and Fort Lauderdale.

Leave a Reply