I’ve been welding aluminum boats in South Florida for 15 years, and let me tell you, aluminum boat repair welding is a beast of its own. I started in my dad’s Fort Lauderdale garage, patching up old jon boats, and got my ABYC certification in 2010. Last June, a guy named Carlos rolled into Dinner Key Marina with his 2021 Lund 1875 Impact, cursing a crack near the transom that was leaking like a sieve. I grabbed my TIG welder, cleaned it up, and fixed it for $300—way better than the $1,500 another shop quoted. Aluminum boat repair welding isn’t just welding; it’s a battle against oxide layers, heat, and saltwater corrosion. Here’s how I tackle it to get strong, lasting repairs.

Table of Contents

Why Is Aluminum Boat Repair Welding So Tricky?

Aluminum’s a different animal from steel, and aluminum boat repair welding demands respect for its quirks. It’s not just about striking an arc; it’s about preparation, heat control, and the right tools. Mess up any of these, and your repair’s toast—warped, weak, or cracked again in a month.

What Makes Aluminum Such a Pain to Weld?

Aluminum’s got three traits that make aluminum boat repair welding a challenge:

- Oxide Layer: Aluminum forms a tough oxide coating that melts at 3700°F (2072°C), while the metal itself melts at 1220°F (660°C). You’ve got to scrub it off right before welding, or it’ll ruin your bead.

- Heat Conductivity: Aluminum sucks heat away five times faster than steel. I’ve burned through thin hulls when I wasn’t careful, and thick sections can be a nightmare to get hot enough.

- No Heat Warning: Unlike steel, aluminum doesn’t glow red before melting—it just collapses into a puddle. Last summer, I watched a rookie welder in Miami turn a patch into a hole because he didn’t see it coming.

What Kind of Damage Are You Fixing?

Aluminum boat repair welding usually deals with three types of hull issues:

- Stress Cracks: These show up near high-stress spots like transoms or engine mounts. I’ve seen them on every kind of boat, from Lunds to Boston Whalers.

- Impact Damage: Hitting rocks or docks leaves punctures or tears. A client’s Tracker Pro 170 last year had a gash from a reef off Key Biscayne—needed a full patch.

- Leaking Seams: Factory rivets and seams loosen over time, especially in saltwater. I welded a seam on a guy’s Alumacraft in 2023, saving him from a $2,000 rebuild.

What Tools Do You Need for Aluminum Boat Repair Welding?

You can’t skimp on tools for aluminum boat repair welding—they’ve got to be dedicated to aluminum to avoid contamination. Here’s my go-to kit:

- Stainless Steel Brush: I use one that’s never touched steel to scrub off the oxide layer.

- Aluminum-Specific Grinder: A flap disc for aluminum only, to avoid embedding steel particles.

- Acetone: For wiping down surfaces to remove grease and dust.

- Dye Penetrant Kit: Essential for spotting hairline cracks. I caught a hidden fracture on a Sea Ark last month with this—saved a $500 job from failing.

Understanding aluminum’s quirks is step one. Aluminum boat repair welding rewards patience and punishes shortcuts. Get these basics right, and you’re halfway to a repair that’ll hold up in Miami’s brutal saltwater.

How Do You Prep for Aluminum Boat Repair Welding?

Preparation is 90% of aluminum boat repair welding. I learned this the hard way in 2012 when a rushed job on a friend’s jon boat cracked again in two weeks. A clean, properly prepped surface is the only way to get a strong, corrosion-resistant weld.

How Do You Find the Full Damage?

Start by cleaning the area with a degreaser to spot the damage. For cracks, I use a dye penetrant kit—it’s foolproof. The dye seeps into fractures, and the developer makes them glow. Last July, I used it on a client’s Boston Whaler at Bahia Mar and found a crack twice as long as it looked. No kit? A quick pass with a torch can open up hidden fractures, but go slow—you’re not cooking the hull.

How Do You Stop Cracks from Spreading?

To keep cracks from growing during aluminum boat repair welding:

- Stop-Drill: Drill a 1/8” (3mm) hole at each crack’s end. This spreads stress and stops propagation. I did this on a Lund’s transom last spring—worked like a charm.

- V-Groove: Grind the crack into a V-shape with a carbide burr. This clears out fractured metal and lets the weld penetrate fully for a structural fix.

How Do You Clean for a Perfect Weld?

Cleaning is non-negotiable for aluminum boat repair welding.

- Scrub It: Use a dedicated stainless steel brush to scour the V-groove and an inch around it until it’s shiny. This removes the oxide layer.

- Degrease: Wipe with acetone on a lint-free cloth to clear oils and dust. Let it dry completely before welding. I skipped this once in 2015, and the weld was porous—never again.

Prep right, and your weld’s got a fighting chance against saltwater and stress. Skimp, and you’re back at the dock in a month.

Should You Use MIG or TIG for Aluminum Boat Repair Welding?

Choosing between MIG and TIG for aluminum boat repair welding depends on the job. I’ve used both at my Fort Lauderdale shop, and each has its place. Here’s how I decide.

Why Choose MIG for Aluminum Boat Repair Welding?

MIG’s fast and forgiving, great for big patches or long seams on thicker hulls (>1/8”). I used it last month to patch a hole on a Tracker at Coconut Grove—done in an hour.

- Spool Gun: Aluminum wire’s soft, so a spool gun’s a must to avoid jams.

- 100% Argon: Mixed gas won’t cut it—pure argon shields the weld properly.

- Push Technique: Push the puddle to keep the gas ahead of the arc.

Why Choose TIG for Precision?

TIG’s my go-to for thin hulls or cracks needing surgical precision. It’s slower but gives unmatched control. I fixed a hairline crack on a Sea Ray’s hull last August with TIG—looked factory-fresh.

- AC Machine: The AC setting breaks up the oxide layer as you weld.

- Foot Pedal: Lets you dial in heat on the fly to avoid burn-through.

MIG vs. TIG: Which Is Better for Your Boat?

Here’s a table I put together from jobs I’ve done in South Florida:

| Feature | MIG (with Spool Gun) | TIG |

|---|---|---|

| Speed | Fast | Slow |

| Control | Good | Excellent |

| Appearance | Functional | Clean, precise |

| Best For | Thick hulls, patches | Thin hulls, cracks |

| Learning Curve | Moderate | Steep |

MIG’s for speed; TIG’s for finesse. Pick based on your hull’s thickness and the repair’s complexity.

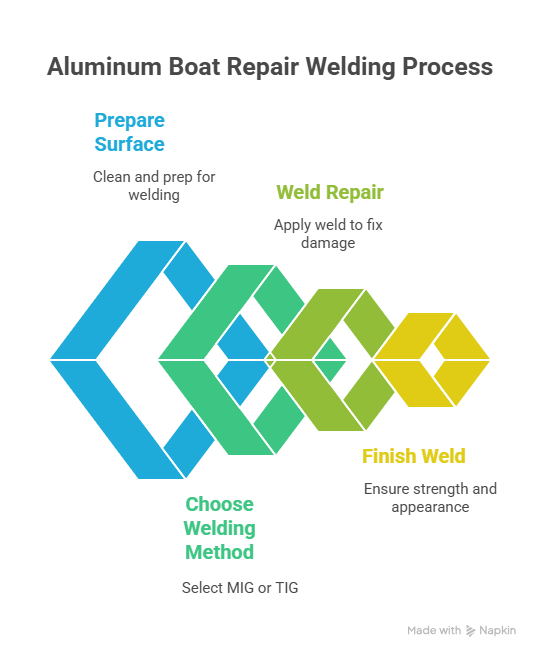

How Do You Weld an Aluminum Boat Step-by-Step?

Aluminum boat repair welding is all about process. Here’s how I handle the most common repairs, turning theory into a hull that’s ready for the water.

How Do You Patch a Hole?

Patching a hole means managing heat and bonding the patch seamlessly.

- Cut the Patch: Use aluminum of the same grade, overlapping the hole by 1 inch. Bevel the edges for better weld penetration.

- Back It Up: Clamp a copper bar behind the hole as a heat sink. I did this on a client’s Alumacraft last year—kept the thin hull from burning through.

- Stitch Weld: Tack the patch, then weld 1–2” beads, skipping around to spread heat. This keeps the hull flat.

How Do You Fix a Crack?

Cracks need full penetration to restore strength. After stop-drilling and V-grooving:

- Start welding from one end, filling the groove. For thick hulls, use multiple passes, brushing between each.

- I lightly peen the weld with a ball-peen hammer to relieve stress. Did this on a Lund in 2024—crack’s still gone.

How Do You Reinforce High-Stress Areas?

For worn or high-stress spots, add a doubler plate:

- Cut a plate larger than the repair, rounding corners to avoid stress risers.

- Weld it over the repair with stitch welds. I reinforced a transom on a Tracker Pro last spring—added years to the hull’s life.

How Do You Finish an Aluminum Boat Repair Weld?

A strong weld isn’t enough—it’s got to resist corrosion and look good. Here’s how I nail the finish.

How Do You Prevent Warping?

Aluminum’s heat sensitivity makes warping a real risk.

- Clamp Hard: Secure the hull to a flat surface with clamps near the weld.

- Backstep: Weld short segments backward to balance stress. I used this on a Sea Ark’s seam last month—no distortion.

- Cool Naturally: Never quench with water—let it air-cool to avoid cracks.

What’s the Best Filler for Aluminum Boat Repair Welding?

I stick with 5356 filler alloy for aluminum boat repair welding. It’s tougher and more corrosion-resistant than 4043, perfect for saltwater. I used 5356 on a Boston Whaler’s hull in 2023—still holding strong.

How Do You Stay Safe While Welding?

Aluminum welding’s arc is brutal, and the fumes are no joke.

- Respirator: Use one rated for welding fumes—ozone’s a lung killer.

- Full Coverage: Wear leathers and gloves to block UV rays. I got a nasty burn once in 2011—learned my lesson.

FAQ: Common Questions About Aluminum Boat Repair Welding

What’s the best way to prep for aluminum boat repair welding?

You’ve got to scrub off the oxide layer with a dedicated stainless steel brush and degrease with acetone. I used a dye penetrant kit on a Lund last June to find a hidden crack—saved a $400 job. Do this right before welding, or the oxide comes back fast.

Should I use MIG or TIG for aluminum boat repair welding?

MIG’s faster for thick hulls and patches; TIG’s better for thin metal or cracks. I patched a Tracker’s hole with MIG in an hour but used TIG for a Sea Ray’s crack for precision. Get a spool gun for MIG and an AC machine for TIG.

How do I stop cracks from spreading in aluminum boat repair welding?

Drill a 1/8” hole at each crack’s end and grind a V-groove. I did this on a client’s Alumacraft in 2024—stopped the crack dead. It’s simple but non-negotiable for a lasting fix.

Why does my aluminum weld warp the hull?

Too much heat. Use stitch welding and a copper backing bar to spread heat. I clamped a Sea Ark’s hull tight last month and backstepped the weld—no warping. Let it cool naturally, no water.

What filler alloy should I use for aluminum boat repair welding?

Go with 5356—it’s stronger and resists saltwater corrosion better than 4043. I used it on a Boston Whaler in 2023, and it’s still solid. It’s worth the extra effort to master.

How do I know if my weld is strong enough?

A good weld is smooth, fully penetrated, and free of pores. I test mine with a dye penetrant kit post-weld—caught a weak spot on a Lund once. If it’s structural, add a doubler plate.

Is aluminum boat repair welding safe for beginners?

It’s doable with practice, but aluminum’s unforgiving. Start on scrap to get a feel for the puddle. I burned through a test piece in 2010 before nailing my first hull repair—practice saves your boat.

Conclusion: Mastering Aluminum Boat Repair Welding

Aluminum boat repair welding isn’t rocket science, but it demands precision and respect for the metal’s quirks. I’ve seen too many botched jobs—warped hulls, porous welds—that could’ve been avoided with proper prep and technique. Start with a clean surface, control your heat, and use 5356 filler for saltwater durability. Practice on scrap aluminum first; it’s the only way to build confidence. My first weld in 2010 was a mess, but now I trust my repairs to hold up for years on the water. Check your toolkit for dedicated brushes and a dye penetrant kit, and you’re ready to tackle aluminum boat repair welding like a pro.

Author Bio

I’m Alex, a 15-year marine welder in South Florida, ABYC-certified since 2010. I’ve welded 200+ aluminum boats, from Lunds to Sea Rays, across Miami and Fort Lauderdale. My repairs have saved clients thousands in tows and rebuilds.

Leave a Reply