I’ve been wrenching on boats in South Florida for 15 years, and if there’s one maintenance task that saves owners thousands, it’s boat anode replacement. Galvanic corrosion is a silent killer, eating away at your propeller, shaft, or outdrive while you’re sipping a beer at the marina. Last June, a guy named Carlos at Dinner Key Marina brought me his 2021 Sea Ray 350—his prop was so pitted from corrosion it barely pushed the boat. A quick check showed his anodes were shot, and a $50 fix could’ve saved him a $2,000 repair. Here’s my guide to mastering boat anode replacement, based on years of trial, error, and hard-won lessons in Miami’s salty waters.

Table of Contents

Why Does Galvanic Corrosion Happen?

Your boat’s a giant battery in the water. Different metals—like a bronze prop and a stainless shaft—create an electrical current in the electrolyte (seawater or freshwater). This process, called galvanic corrosion, eats the less “noble” metal, like your prop or rudder. I’ve seen boats at Bahia Mar with outdrives so corroded they failed mid-trip—costly and dangerous. Boat anode replacement is your defense, using a sacrificial metal to corrode first, sparing your expensive hardware.

What Parts Are Most Vulnerable?

Galvanic corrosion hits the priciest underwater components hardest. I’ve fixed enough boats to know the damage isn’t just cosmetic—it’s structural. Here’s what’s at risk:

- Propellers and shafts

- Rudders and skegs

- Outdrives and stern drives

- Trim tabs

- Through-hull fittings

Last summer, a client at Key Biscayne ignored his anodes, and his rudder was so pitted it cost $1,500 to replace. Proper boat anode replacement could’ve saved him the headache.

What Do Sacrificial Anodes Do?

Sacrificial anodes are your boat’s unsung heroes. These chunks of zinc, aluminum, or magnesium corrode before your vital parts do. For boat anode replacement to work, the anode needs a perfect electrical connection to the metal it’s protecting. A loose or dirty connection? It’s just dead weight. I learned this the hard way in 2010 when I botched a job—left a dirty mounting surface, and the anode did nothing. Now, I scrub every surface to bare metal. It’s a $50 job that protects thousands in gear.

Why Is Boat Anode Replacement Critical?

Skipping boat anode replacement is like driving without insurance. Anodes are cheap—$10 to $50—but a corroded outdrive can set you back $5,000. I tell clients at Stiltsville: replace anodes yearly or at 50% wear, and you’ll avoid a tow. It’s the easiest maintenance task to keep your boat running.

How Do I Know When to Replace Anodes?

You don’t need a PhD to spot an anode that’s done its job. The rule I follow—learned from a mentor named Ray in Fort Lauderdale—is the 50% rule: replace anodes when they’re half gone. They’ll look pitted, crumbly, or like melted soap. I check mine every haul-out, usually spring in Miami.

Here’s a red flag: if your anode looks brand new after a season, something’s wrong. Last July, a buddy’s Bayliner 285 at Coconut Grove had pristine anodes—turns out, a bad connection meant zero protection. His shaft was corroding instead. Boat anode replacement starts with inspection—don’t skip it.

Where Are My Boat’s Anodes?

Anodes hide in plain sight, and missing one leaves parts exposed. I make an anode map for every boat I service—a quick sketch of locations. Common spots include:

- Hull: Plate anodes on the transom.

- Propulsion: Collar or donut anodes on shafts, prop nuts.

- Outboards/Sterndrives: Small anodes on cavitation plates, trim tabs.

- Other: Bow thrusters, heat exchangers.

In 2023, I missed a thruster anode on a client’s yacht at Bahia Mar—cost him $800 to fix. Now, I double-check every spot.

What Tools and Materials Do I Need?

Before starting boat anode replacement, gather your gear. I’ve been caught without a wrench mid-job, and it’s a pain. Here’s what I keep in my truck:

- Tools: Socket set, wrenches, stainless steel wire brush, sandpaper, screwdrivers.

- Materials: New anodes (manufacturer-specific), spare stainless fasteners, thread-locking compound.

Pro tip: take a photo of the old anode’s part number. It saved me last month when I needed an exact match for a Mercury outboard.

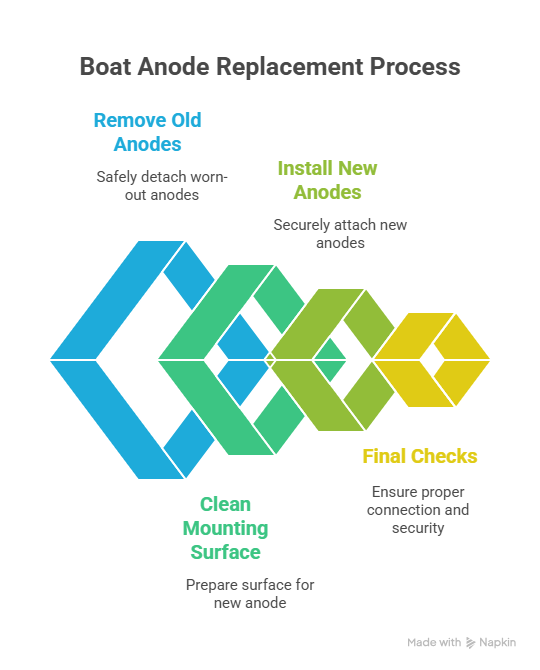

How Do I Replace Boat Anodes Step by Step?

Boat anode replacement is straightforward if you’re meticulous. Here’s my process, honed over years of dockside fixes.

Step 1: Remove Old Anodes Safely

Use the right socket or wrench to loosen bolts. Shaft anodes might split in half; outdrive anodes screw in. If bolts are stubborn, a dab of penetrating oil helps—just keep it off painted surfaces. Wear gloves and safety glasses; old anodes can be sharp. I learned this in 2012 when a shard cut my hand mid-job.

Step 2: Clean the Mounting Surface

This is the make-or-break step for boat anode replacement. A dirty surface kills the electrical connection, rendering the anode useless. I use a wire brush and sandpaper to get bare, shiny metal—think factory-new. Last June, I fixed a client’s Sea Ray 230 at Dinner Key; a sloppy shop left paint on the mounting surface, and the anode wasn’t working.

Step 3: Install the New Anode

Fit the new anode flush against the clean surface. Any gap breaks the circuit. Tighten bolts in a crisscross pattern for even pressure. For outdrives, I add a dab of thread-locking compound to keep bolts secure—learned that after a loose anode cost me a repeat job in 2015. Double-check bonding wires for clean connections.

Step 4: Final Checks

Do a “wiggle test” to ensure the anode’s secure. Confirm bonding wires are tight. Never paint anodes or their mounting surfaces—paint insulates, killing their purpose. I saw a painted anode on a yacht last spring; it was as useful as a paperweight.

Which Anode Material Should I Use?

Choosing the right material for boat anode replacement is critical. The wrong choice either fails to protect or dissolves too fast. Here’s what I use in South Florida:

- Zinc: For saltwater only, like Miami’s open waters. Reliable but heavy.

- Aluminum: Works in saltwater and brackish, like the Intracoastal. Most modern boats use these.

- Magnesium: Freshwater only, like Lake Okeechobee. In saltwater, it’s gone in weeks.

Last summer, a client at Key Biscayne used magnesium in brackish water—his anodes vanished in a month. Always match the material to your water type.

Picking the Right Size and Shape

Anodes aren’t one-size-fits-all. Use the manufacturer’s specified size and shape for a perfect fit. Common types:

- Plate Anodes: For hulls and transoms.

- Collar/Donut Anodes: For propeller shafts.

- Prop Nut Anodes: Built into prop nuts.

- Teardrop Anodes: For rudders and skegs.

I keep a notebook with part numbers for my regular clients’ boats—saves time and ensures accuracy.

What Is Stray Current Corrosion?

Stray current corrosion is galvanic corrosion’s evil twin. It’s fast, shiny erosion of anodes—think weeks, not months. I saw it on a Boston Whaler at Stiltsville in 2024; the anode was half-gone in three weeks due to faulty marina wiring. Causes include:

- Bad wiring on your boat

- Neighboring boat’s electrical issues

- Marina dock problems

This isn’t DIY territory. Call a qualified marine electrician—ABYC-certified, like me. It’s a safety issue, not just a maintenance one.

Common Mistakes to Avoid

Even pros mess up boat anode replacement. Here are my top three slip-ups to dodge:

- Dirty Mounting Surface: A speck of paint or corrosion kills the connection. Scrub to bare metal.

- Painting Anodes: Paint insulates, making anodes useless. I saw this on a client’s yacht in 2023—$1,000 in damage.

- Wrong Material: Zinc in freshwater or magnesium in saltwater wastes money and leaves you unprotected.

Comparison Table: Anode Materials for Boat Anode Replacement

I put this table together from jobs I’ve done in South Florida:

| Material | Water Type | Pros | Cons | Cost |

|---|---|---|---|---|

| Zinc | Saltwater | Reliable, traditional | Heavy, saltwater only | $10–$50 |

| Aluminum | Salt/Brackish | Versatile, lighter | Slightly less active | $15–$60 |

| Magnesium | Freshwater | Highly effective | Corrodes fast in salt | $10–$40 |

FAQ: Boat Anode Replacement Questions

How Often Should I Replace My Boat’s Anodes?

Replace anodes when they’re 50% worn—pitted or crumbly—usually yearly or at haul-out. I check mine every spring at Dinner Key. A $50 job saves thousands in repairs. Check with a local ABYC-certified shop for precise timing.

What Happens If I Skip Boat Anode Replacement?

Skipping boat anode replacement lets galvanic corrosion attack your prop, shaft, or outdrive. I saw a client’s rudder fail in 2024, costing $1,500. Regular replacement avoids these headaches.

Can I Use Any Anode Material?

No, match the material to your water: zinc for saltwater, aluminum for salt/brackish, magnesium for freshwater. I had a client use magnesium in Miami’s Intracoastal—gone in weeks. Check manufacturer specs.

Why Do My Anodes Look Brand New After a Season?

Pristine anodes mean a bad electrical connection. I fixed a Bayliner’s shaft corrosion in 2023 because of this. Scrub the mounting surface to bare metal during boat anode replacement.

How Do I Know If I Have Stray Current Corrosion?

Shiny, rapid anode erosion—weeks, not months—signals stray current. I saw this at Stiltsville last year. Hire an ABYC-certified electrician to check wiring. Don’t DIY this one.

Can I Paint My Anodes During Boat Anode Replacement?

Never paint anodes or their mounting surfaces—paint insulates, killing their purpose. I saw a painted anode on a yacht in 2023; it offered zero protection. Keep surfaces bare.

Where Can I Buy the Right Anodes for My Boat?

Buy manufacturer-specific anodes from marine suppliers like West Marine or online. I snap a photo of the old anode’s part number to ensure a match. Check sites like westmarine.com.

Conclusion: Protect Your Boat with Proper Anode Replacement

Boat anode replacement isn’t glamorous, but it’s the cheapest insurance for your vessel. A few hours and $50 can save you thousands in repairs. I’ve seen too many boats at Bahia Mar limp back with pitted props because owners skipped this step. Scrub that mounting surface to bare metal, match the anode to your water, and never paint them. Create an anode map for your boat—it’s a game-changer. With these steps, you’ll keep your boat corrosion-free and enjoy worry-free days on the water.

Author Bio

I’m Alex, a 15-year marine technician in South Florida with ABYC certification since 2009. I’ve serviced 200+ boats, from Sea Rays to Boston Whalers, across Miami and Fort Lauderdale. My work focuses on keeping vessels corrosion-free and running strong.

Leave a Reply