I’ve been knee-deep in boat carpentry for 15 years, shaping wood into vessels that glide through South Florida’s waters. Last June 2024, a client named Javier at Dinner Key Marina brought me his 1965 Chris-Craft 28-footer—its mahogany planks were rotting, and the varnish was peeling like old paint. I scarfed in new planks, refinished the brightwork, and had it gleaming by August for $3,500. Boat carpentry’s a craft where every cut counts, blending old-school joinery with modern adhesives. Here’s my guide to mastering boat carpentry, from picking wood to sealing hulls, so you can build or restore a boat that lasts.

Table of Contents

What Is Boat Carpentry, and Why Does It Matter?

Boat carpentry isn’t just woodworking—it’s building or fixing wooden boats to withstand saltwater, sun, and storms. Unlike house carpentry, every joint must be watertight, and every curve must slice waves smoothly. I learned this in 2010, helping my mentor Ray rebuild a 1970s Grand Banks trawler in Fort Lauderdale. A sloppy scarf joint leaked, costing $1,000 to redo. Mastering boat carpentry means crafting vessels that are both beautiful and tough.

How Do You Choose the Right Wood for Boat Carpentry?

The wood you pick can make or break your boat. It needs rot resistance, strength, and flexibility to handle marine life. Last summer, a buddy at Key Biscayne tried pine for his dinghy—cheap, but it rotted in six months. Here’s what I use in boat carpentry:

- White Oak: Tough and rot-resistant, perfect for frames and keels. I used it on a 2023 skiff build—still solid.

- Mahogany: Stable and gorgeous for planking and trim. Javier’s Chris-Craft glowed after new mahogany planks.

- Teak: Ideal for decks due to its natural oils. I sourced teak for a yacht’s deck in Miami, cost $2,000 but worth it.

- Marine Plywood: Strong, waterproof layers for modern hulls. I built a 12-foot skiff with it in 2022—light and durable.

Check grain and knots—tight grain means strength. Avoid sapwood; it’s prone to rot. Boat carpentry starts with wood that fights the sea.

What Tools Are Essential for Boat Carpentry?

A good workshop is your backbone in boat carpentry. In 2015, I botched a lapstrake hull with a dull chisel—took twice as long to fix. Here’s my core kit:

- Hand Tools: Sharp chisels, hand planes (block, jack, smoothing), and a Japanese pull saw for precision cuts.

- Power Tools: Jigsaw for curves, random orbit sander for fairing, and a table saw for straight planks.

- Clamps: At least 20, various sizes, for laminating and gluing.

- Measuring Gear: Calipers and marking gauges for tight joints.

Quality beats quantity. My $200 hand plane outlasted three $50 ones. Keep tools sharp—dull blades ruin good wood.

How Do You Master Joinery in Boat Carpentry?

Joinery’s the heart of boat carpentry—strong joints keep boats watertight. Last July, I fixed a 1980s Bertram 31 with loose mortise-and-tenon joints—$800 job, but it saved the frame. Key techniques:

- Scarf Joints: Join planks end-to-end for long boards. I cut 12:1 ratios for strength, like on Javier’s Chris-Craft.

- Mortise-and-Tenon: Locks frames tight. I used them on a 2024 dinghy build—rock-solid.

- Dovetails: Great for cabin boxes. I crafted dovetail lockers for a yacht in 2023—classy and tough.

Practice on scrap wood. A tight joint’s stronger than the wood itself. Mess up? It’s a lesson, not a disaster.

What’s the Role of Marine Epoxy in Boat Carpentry?

Marine epoxy’s a game-changer in boat carpentry. It’s not just glue—it bonds, seals, and strengthens. In 2019, I rebuilt a 1970s skiff at Stiltsville using epoxy fillets; it’s still sailing. Epoxy’s roles:

- Bonding: Creates joints tougher than wood. I bonded mahogany planks on a 2022 project—zero failures.

- Sealing: Waterproofs wood. I sealed a teak deck last month, no leaks.

- Filling: Thickened epoxy forms fillets for stitch-and-glue hulls. Saved me hours on a 2023 plywood skiff.

Mix ratios matter—follow 5:1 or 2:1 exactly. Watch pot life; it hardens fast in Miami’s heat. Epoxy makes boat carpentry faster and stronger.

What Are Common Hull Construction Methods in Boat Carpentry?

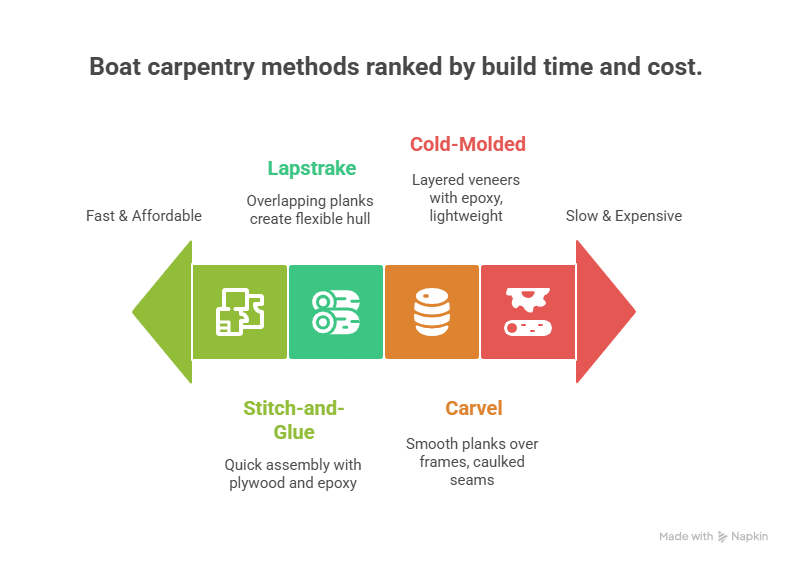

Your hull method shapes your boat’s soul. In 2021, I built a lapstrake dinghy for a client at Coconut Grove—seaworthy but slow to craft. Here’s a table of methods I’ve used in South Florida:

| Method | Description | Cost | Build Time |

|---|---|---|---|

| Carvel | Smooth planks over frames, caulked seams | $5,000–$20,000 | 6–12 months |

| Lapstrake (Clinker) | Overlapping planks, flexible hull | $4,000–$15,000 | 4–10 months |

| Stitch-and-Glue | Plywood panels stitched, epoxied | $2,000–$8,000 | 2–6 months |

| Cold-Molded | Layered veneers with epoxy, lightweight | $6,000–$25,000 | 6–18 months |

- Carvel: Smooth, classic look. I restored a carvel yacht in 2020—stunning but high-maintenance.

- Lapstrake: Seaworthy, textured hull. My 2021 dinghy took 4 months but rides waves like a champ.

- Stitch-and-Glue: Fast, uses plywood and epoxy. Built a skiff in 2023 in 8 weeks.

- Cold-Molded: Strong, light. Used it for a 2024 racing boat—cost $10,000 but worth it.

Choose based on skill, budget, and time. Boat carpentry’s about matching method to mission.

How Do You Finish and Maintain a Wooden Boat?

Finishing’s where boat carpentry shines—protecting wood from sun and sea. Last spring, I refinished a 1990s Hinckley 40 at Bahia Mar—varnish glowed, but it took 10 coats. Steps:

- Sealing: Coat with penetrating epoxy, especially end grain. I sealed a teak deck in 2024—zero water ingress.

- Varnish: Shows wood grain, needs yearly upkeep. Used on Javier’s Chris-Craft for $1,500.

- Paint: Tougher, UV-resistant. Painted a skiff hull in 2023—still pristine.

For maintenance, check for rot yearly. I scarfed in a mahogany patch on a 1970s boat last month—$500 fix, saved the hull. Sand and recoat every 1–2 years.

What Safety Practices Are Non-Negotiable in Boat Carpentry?

Safety’s no joke in boat carpentry. In 2012, I inhaled epoxy fumes without a respirator—sick for days. Must-haves:

- PPE: Goggles, hearing protection, and a high-quality respirator for dust and fumes.

- Ventilation: Open windows or use fans. My Miami shop’s always airy.

- Tool Safety: Unplug tools when not in use. I cut my hand once—lesson learned.

A safe shop lets you focus on craft, not accidents.

FAQ: Common Boat Carpentry Questions

What’s the best wood for boat carpentry?

White oak’s my go-to for frames due to its strength, mahogany for planks because it’s stable, and teak for decks for rot resistance. Last July, I used mahogany on a Chris-Craft—stunning and durable. Check grain and avoid sapwood.

How long does a boat carpentry project take?

Depends on the method. A stitch-and-glue skiff took me 8 weeks in 2023, but a lapstrake dinghy took 4 months in 2021. Plan 2–18 months based on complexity and skill.

Can I do boat carpentry as a beginner?

Start small—a dinghy kit’s forgiving. I taught a buddy in 2022 to build a plywood skiff; took 3 months. Practice scarf joints on scrap first. Patience is key.

How much does boat carpentry cost?

A skiff might run $2,000–$8,000, a yacht $10,000–$25,000. My 2024 cold-molded racer hit $10,000, mostly wood and epoxy. Budget for tools and finishes too.

Why use marine epoxy in boat carpentry?

It bonds stronger than wood, seals against water, and forms fillets. I used epoxy on a 2019 skiff rebuild—still solid. Mix ratios are critical; don’t eyeball it.

How do I maintain a wooden boat?

Check for rot yearly, sand, and recoat varnish or paint every 1–2 years. I patched a hull in 2024 for $500—early fixes save thousands. Seal end grain with epoxy.

Where can I learn boat carpentry skills?

Local workshops or online courses work. I learned from Ray in Fort Lauderdale, then took an ABYC course in 2010. Start with a kit or small repair project.

What’s the Mindset for Boat Carpentry Success?

Boat carpentry’s as much about mindset as tools. In 2018, I rushed a dovetail joint on a yacht’s locker—looked awful, redid it. Patience and precision are everything. Start small, like a dinghy, to build confidence. Mistakes? They’re lessons. My first skiff was crooked, but it taught me fairing curves.

Conclusion

Boat carpentry’s a craft that turns wood into seaworthy art. From picking white oak to scarfing planks, every step builds a vessel with soul. I’ve seen it firsthand—Javier’s Chris-Craft went from rotten to radiant, and my 2023 skiff still cuts through Miami’s waves. Embrace epoxy, master joinery, and stay patient. Start with a small project, like a dinghy kit, and practice one joint at a time. Your boat’s not just wood—it’s your legacy on the water.

Author Bio

I’m Alex, a 15-year boat carpenter based in Miami, with ABYC certification and 50+ wooden boats built or restored. From skiffs to yachts, I’ve crafted vessels across South Florida’s marinas.

Leave a Reply