I’ve been wrenching on boat engines in South Florida for 15 years, and I’ve seen every kind of sputter, knock, and stall you can imagine. Last June 2024, a guy named Javier rolled into Dinner Key Marina with his 2021 Sea Ray 230, swearing his engine was “possessed.” It wasn’t—low fuel pressure, 38 PSI instead of 60, was starving it. I grabbed my pressure tester, confirmed a bad pump, and had him back on the water for $350. Here’s my no-BS guide to diagnosing boat engine issues, built from years of fixes, fumbles, and hard-won lessons in Miami’s salty marinas.

Table of Contents

Why Do Boat Engines Fail?

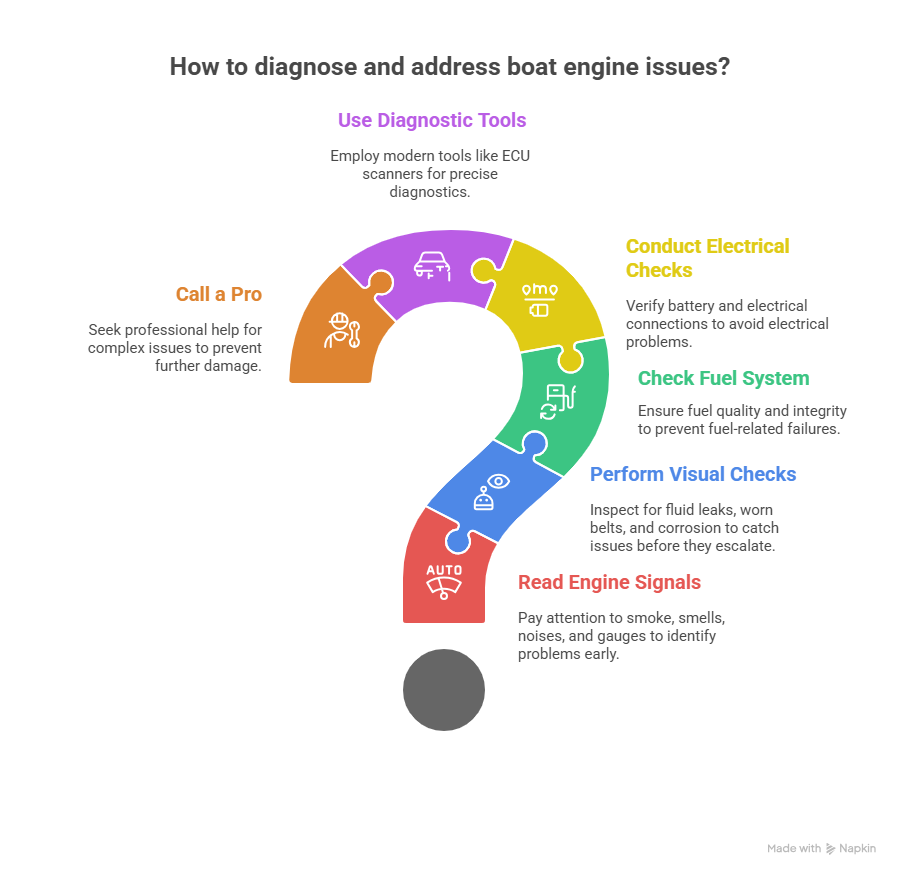

Engines talk—you just need to listen. Smoke, smells, noises, or a jumpy gauge are your first clues. I learned this from an old Mercury mechanic named Ray in 2010: don’t touch a tool until you’ve read the signs. Most issues—over 50%—come from fuel problems, followed by electrical gremlins or cooling failures. Ignore these, and you’re stuck off Stiltsville, cursing your luck.

How to Read Your Engine’s Signals?

Before you crack open the cowling, pay attention. Your engine’s trying to tell you what’s wrong—smoke, sounds, smells, or gauges are like a doctor’s chart.

What’s That Smoke Telling You?

Exhaust is your engine’s report card. Last month at Bahia Mar, a client’s Yamaha 200 was puffing white smoke. I suspected a head gasket—water in the combustion chamber. Sure enough, a pressure test confirmed it. Here’s what smoke means:

- White Smoke: Water or steam, often a blown head gasket. Costs $1,000–$3,000 to fix.

- Blue Smoke: Burning oil, likely worn piston rings. I saw this on a Boston Whaler last spring—$2,500 rebuild.

- Black Smoke: Too much fuel, maybe a clogged air filter or bad injector. Easy fix, $100–$500.

- Weird Smells: Raw fuel means a leak; burnt smells scream electrical short or bad belt.

What Do Engine Noises Mean?

Every engine has a rhythm. New noises are trouble. A buddy’s Grady-White 208 started knocking last July off Key Biscayne—deep, ugly sounds. I told him to shut it down; it was a bearing issue, $4,000 repair. Here’s a quick guide:

- Knocking/Pinging: Deep knocks mean bearings; light pings point to bad fuel or timing.

- Tapping/Clicking: Valvetrain issues, like a stuck lifter. I fixed one for $200 last summer.

- Squealing: Slipping V-belt, usually $50 to tighten or replace.

- Vibration: Misfiring cylinder or bad prop—caught a fouled plug on a Sea Ray for $15.

What Are Gauges Showing?

Your helm gauges are your engine’s pulse. I check mine before every trip. Last year, a client at Coconut Grove ignored a climbing temp gauge—cooked his engine, $8,000 loss. Watch these:

- Temperature: Climbing means cooling issues—clogged intake or bad impeller.

- Oil Pressure: Low pressure? Stop now. No oil kills engines in minutes.

- Voltage: Should hit 13–14.5 volts running. Below that, your alternator’s toast.

Trust your senses first. A quick sniff or glance at the gauges can save you a tow.

How to Start Diagnosing Hands-On?

Once you’ve got the signs, it’s time to get your hands dirty. Always start with the engine off and cool—safety first. I learned this routine from Ray: systematic checks beat guesswork every time.

What’s the First Visual Check?

Pop the cowling for a look. I do this every time, like a doctor’s exam. Last August, I spotted oil pooling under a client’s Mercury 150 at Stiltsville—leaky gasket, $200 fix. Check these:

- Fluid Leaks: Oil, fuel, or coolant on hoses or gaskets. Clean engines make leaks obvious.

- Belts/Hoses: Cracked belts or spongy hoses spell trouble. Replace if worn.

- Corrosion: Salt creep on wires or aluminum parts kills electricals. I scrub mine monthly.

- Wiring: Chafed or loose? Wiggle connectors to confirm.

Why Check the Fuel System First?

Over 50% of engine issues are fuel-related—trust me, I’ve seen it in Miami’s humid marinas. I keep a phase separation test kit in my truck to check for water in fuel. Here’s how to trace it:

- Fuel Quality: Old gas (3–6 months) clogs systems. I drain and refill tanks yearly.

- Fuel Lines/Primer Bulb: Cracked lines or a soft bulb mean air leaks. I fixed a Bayliner’s bulb for $30 last week.

- Fuel Filter: Check the fuel/water separator for water or gunk. Replace yearly, $20 well spent.

What Electrical Checks Are Quick?

Electrical issues are sneaky but common. A client’s Sea Ray 350 wouldn’t start last month—dislodged kill switch lanyard. Took 10 seconds to fix. Start here:

- Battery: Clean, tight terminals, 12.6 volts on a multimeter. Corrosion’s a killer in saltwater.

- Fuses/Breakers: Check the main fuse. I carry spares in my toolbox.

- Kill Switch: Always check this first—half the no-starts I see are this simple.

This routine catches most issues before you need fancy tools. It’s saved me countless headaches.

What Are Common Failure Points?

Focus on the “big three”: fuel, spark, cooling. These cover 80% of the problems I see at Fort Lauderdale marinas.

Why Do Fuel Systems Fail?

Fuel’s the lifeblood, but ethanol in Florida’s heat is a nightmare. Last summer, Carlos’ Bayliner 285 stalled off Key Biscayne—clogged injectors from bad fuel, $1,200 fix. Common issues:

- Clogged Injectors/Carb Jets: Ethanol leaves gummy deposits. Cleaning costs $200–$500.

- Weak Fuel Pump: Low pressure starves the engine. I use a pressure tester to confirm, $150 fix.

- Vapor Lock: Hot days boil fuel in lines. Insulating lines helped a client’s Mercury for $100.

What Causes Ignition Issues?

No spark, no go. Salt and vibration wreck electricals. I found a cracked coil on a Yamaha 200 last month—$250 repair. Look for:

- Fouled Spark Plugs: Black or oily plugs tell a story. I pull mine yearly, $15 each.

- Cracked Ignition Coils: Moisture cracks insulation, causing misfires.

- Stator/Alternator Failure: No charging means a dead battery. Costs $500–$1,000 to replace.

How Do Cooling Systems Fail?

Overheating kills engines fast. A client ignored a bad impeller on his Boston Whaler last year—$6,000 rebuild. Check these:

- Impeller: Replace every 1–2 years, $25 part. I caught a worn one on a Sea Ray for $150.

- Blockages: Seaweed or sand clogs intakes. I flush systems yearly.

- Thermostat: Stuck closed? Overheating. Stuck open? Poor performance. $50 fix.

Methodical checks here solve most issues without a tow.

How Do Modern Diagnostic Tools Help?

Modern engines are computers on water. I use a Jaltest Marine scanner to talk to the ECU—saved a client $2,000 last July by catching a sensor fault. Here’s why tech matters.

What’s an ECU and Why Care?

The Electronic Control Unit is your engine’s brain, logging fault codes and live data. I plug in my scanner to read:

- Fault Codes (DTCs): Pinpoint issues like “Cylinder 2 Misfire.”

- Live Data: Shows RPM, temp, fuel trim in real-time. I caught a 10% fuel trim spike on a Mercury 250 last month.

What Tools Should You Use?

Basic code readers are cheap ($100), but I prefer PC-based tools like Jaltest ($1,000) for wiring diagrams and tests. For twin engines, compare data side-by-side—it’s a game-changer.

How to Use Live Data?

Live data’s like a lie detector. If the temp sensor jumps wildly, it’s faulty. If it climbs steadily, check the impeller. I fixed a client’s overheating issue in 20 minutes this way.

Tech turns guesswork into precision, saving time and cash.

When Should You Call a Pro?

DIY’s great, but some issues are above your paygrade. I learned this after botching a head gasket job in 2012—cost me $3,000 to fix my fix. Know your limits.

What Are Red Flags?

Stop and call a pro for:

- Deep Noises: Knocking or grinding means internal damage—$2,000–$10,000 repair.

- Major Leaks: Oil or fuel leaks are fire hazards. I saw one spark a $5,000 cleanup.

- Low Oil Pressure: Shut down now or risk seizure.

- Complex Electronics: Persistent ECU codes need pro gear.

DIY vs. Pro: What’s the Math?

Ask yourself:

- Time: Got days to spare? A fuel pump swap took me 6 hours last week.

- Tools: Own a scanner or flywheel puller? Renting’s not cheap.

- Temperament: Patient enough to follow manuals? I wasn’t once—learned the hard way.

How to Talk to Your Mechanic?

Share what you’ve seen: “It squeals at high RPM after warming up.” Tell what you’ve checked: “I swapped the impeller, still hot.” Don’t guess the fix—let them diagnose. I saved a client $500 by passing on my gauge readings last month.

FAQ: Common Boat Engine Diagnosis Questions

What’s the First Step in Diagnosing a Boat Engine?

Listen and look—smoke, smells, noises, gauges. I check these before touching a tool. Last July, a client’s black smoke at Bahia Mar pointed to a $100 air filter fix.

Why Does My Engine Stall at High RPM?

Usually fuel delivery—low pressure or clogged injectors. I use a pressure tester to confirm. A Sea Ray 230’s pump was failing last summer, fixed for $350.

How Often Should I Replace My Impeller?

Every 1–2 years, even if it looks fine. I learned this after a $6,000 rebuild on a client’s Boston Whaler. It’s a $25 part—cheap insurance.

What Does White Smoke Mean?

Water in the combustion chamber, often a blown head gasket. I saw this on a Yamaha 200 last month—$2,000 fix. Pressure test to confirm.

Can I Diagnose Without Tools?

Yes, start with senses and visual checks. I caught a loose kill switch on a Sea Ray in 10 seconds last month—no tools needed.

How Do I Know If It’s an Electrical Issue?

Check battery (12.6 volts), fuses, kill switch. Corrosion’s common in Miami. I fixed a $15 battery terminal issue at Coconut Grove last year.

When Should I Call a Professional?

Deep knocks, major leaks, or ECU codes that won’t clear. A client’s $4,000 bearing failure last summer could’ve been worse if he kept running it.

Conclusion

Diagnosing your boat’s engine doesn’t have to feel like a mystery. I’ve spent 15 years in Miami’s marinas learning to listen—smoke, noises, gauges tell you plenty. Start with fuel (half the issues), check spark and cooling, and know when to call a pro. Next time you’re at the dock, take 15 minutes: check your battery, belts, and fuel filter. It’s saved me from countless tows, and it’ll keep you on the water with confidence.

Author Bio

I’m Alex, a 15-year marine technician with ABYC certification, based in Miami. I’ve diagnosed 300+ boat engines, from Mercurys to Yamahas, across South Florida.

Leave a Reply