That Gut-Punch Feeling Miles from Shore

I’ll never forget the look on Mark’s face. We were out on his Bertram off Fort Lauderdale, and the engine alarm screamed. Temperature gauge pinned in the red. That gut-punch feeling every boat owner knows? Yeah, that was it. The culprit, as it often is, was that little box tucked away next to the engine that most people ignore until it’s too late: the heat exchanger.

As a marine mechanic in South Florida for the better part of two decades, I’ve seen this scene play out a hundred times. A neglected heat exchanger is a time bomb. It’s the single most important part of your engine’s cooling system, its life support. When it fails, your engine cooks itself.

So, let’s talk about it—mechanic to boater. No jargon, no nonsense. We’re going to cover how to spot trouble, how a proper boat heat exchanger repair is done, and how to keep yours from ever giving you that gut-punch feeling in the first place.

Table of Contents

The Unsung Hero in Your Engine Room

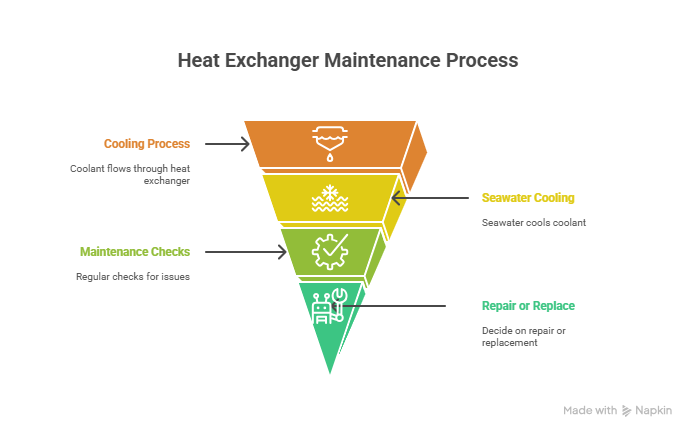

Think of your heat exchanger like your car’s radiator, but instead of air, it uses seawater to do the cooling. Your engine itself has a closed loop of fresh water and coolant running through it, just like a car. That coolant gets hot, flows into the heat exchanger, and passes through a bundle of small tubes. Seawater is pumped from outside and flows around these tubes, pulling the heat out before being spat out with the exhaust.

The two fluids never touch. This is brilliant because it means corrosive, gritty saltwater never gets inside your engine block. This is the whole ballgame. A good heat exchanger is the difference between an engine that lasts 3,000 hours and one that lasts 10,000.

But here’s the problem: that constant flow of saltwater brings marine growth, salt buildup, and all sorts of gunk. Internally, the tubes can get clogged. Externally, the seawater is trying to eat the metal. Eventually, it gets overwhelmed, and that’s when you need a boat heat exchanger repair.

That Screaming Alarm: How to Spot Trouble Early

Your engine usually gives you warnings before it totally overheats. You just have to know what to look and listen for.

- The Temp Gauge Creeps Up: This is the most obvious sign. If your engine is running even 5-10 degrees hotter than it used to, something’s wrong. Don’t ignore it.

- Weak Water Flow from the Exhaust: Go look at the back of your boat. You should have a strong, steady stream of water coming out with the exhaust. If it’s weak or sputtering, your raw water side is likely clogged. This is a huge red flag pointing to a needed boat heat exchanger repair.

- Visible Leaks: Look for drips or white/green crusty stains around the end caps of the heat exchanger. That’s coolant escaping.

Before you call me or another mechanic, do a quick check. Is your sea strainer clean? Are the hoses in good shape? Sometimes you get lucky and it’s a simple fix. But if those are clear, your focus should turn to the heat exchanger itself.

Getting Your Hands Dirty: The Real Deal on Boat Heat Exchanger Repair

Alright, let’s say you’ve confirmed the problem is the heat exchanger. A proper boat heat exchanger repair isn’t just a quick patch job; it’s a full service. Here’s how I tackle it.

First, safety. Let the engine cool completely. Shut off the seacock. Drain the coolant and the raw water side. It’s a messy job, so have buckets and rags ready.

- The Teardown: Carefully remove the end caps and pull out the tube stack (the core). I lay everything out on a clean bench and take pictures as I go. It’s amazing how many “extra” parts people end up with when they don’t. This is when I check the sacrificial anodes inside—if they’re more than half gone, they get replaced. No questions asked.

- The Cleaning: This is 90% of the job. I start by mechanically cleaning the tubes with a soft wire brush or a cleaning rod to get the big chunks of gunk and scale out. Then, it’s time for a chemical bath. A mild acid solution like CLR or a dedicated marine descaler works wonders. You let the core soak, and it dissolves all the stuff you couldn’t reach. A thorough freshwater flush afterwards is critical to neutralize the acid.

- The Fix: With everything clean, I inspect for damage. Tiny pinholes in the tubes or housing can sometimes be fixed with marine-grade epoxy like Marine-Tex or even brazing. But honestly, if the core looks like Swiss cheese, it’s time for a replacement. A successful boat heat exchanger repair depends on a solid foundation.

- Reassembly with New Gaskets: This is a rule I never break: always use new gaskets and O-rings. Reusing old, compressed ones is asking for a leak. It’s a $20 part that saves you a $2,000 headache.

- The Pressure Test: Before the unit goes back on the engine, I pressure test it on the bench. This confirms my boat heat exchanger repair is solid and there are no hidden leaks. Skipping this step is just lazy.

The Big Question: Patch it or Pitch it?

Clients always ask me if they should repair their old unit or just buy a new one. It comes down to age, damage, and cost. Here’s a quick table I use to help them decide.

| Factor | Repair It (Patch) | Replace It (Pitch) | My Two Cents |

|---|---|---|---|

| Problem | Minor leaks at end caps, heavy fouling/clogging. | Cracked housing, multiple leaking tubes, severe internal corrosion. | A good cleaning can work miracles, but you can’t fix rotten metal. |

| Age of Unit | Less than 10 years old. | Over 10-15 years, or showing signs of repeated failures. | Older units are often made with less robust materials. It’s a ticking clock. |

| Estimated Cost | $400 – $1,200 | $1,500 – $4,000+ (depending on engine) | If the repair cost is over 50% of a new unit, I almost always recommend replacement. |

| Outcome | Buys you a few more seasons of reliable service. | Peace of mind for the next decade. New warranty. | For a cruiser heading offshore, a new unit is cheap insurance. This isn’t where you want to gamble. |

Ultimately, a full replacement is often the best long-term value, especially if your boat’s engine is critical to your safety and enjoyment. A proper boat heat exchanger repair can be effective, but it has its limits.

How to Keep Me from Visiting Your Boat (For This Problem, Anyway)

Preventative maintenance is the key. You can drastically extend the life of your heat exchanger with a few simple habits.

- Freshwater Flush: If you’re in saltwater, flushing your engine with fresh water after each trip works wonders. It prevents salt from sitting inside and corroding everything.

- Check Your Anodes: Your heat exchanger has its own little sacrificial anodes. Check them at least once a year and replace them when they’re about half-gone. This is the easiest and cheapest part of boat heat exchanger repair.

- Keep Your Coolant Clean: Use the coolant your engine manufacturer recommends and change it on schedule. Clean coolant protects the inside of the system.

Doing this simple maintenance is the difference between a planned, affordable service and an emergency, wallet-draining boat heat exchanger repair call.

The Bottom Line

That heat exchanger is working hard every second your engine is running. Ignoring it is one of the most expensive mistakes you can make as a boat owner. The key is to shift from reactive repairs to proactive maintenance.

Here’s what you need to remember:

- Listen to Your Engine: That temperature gauge is your best friend. If it starts creeping up, investigate immediately.

- Maintenance Isn’t Optional: Regular cleaning and anode replacement will save you thousands. A complete boat heat exchanger repair is far more expensive than a few hours of prevention.

- Know When to Call a Pro: While cleaning is DIY-able, a full-blown boat heat exchanger repair or replacement is often best left to an experienced mechanic.

- Don’t Be Penny-Wise and Pound-Foolish: If your heat exchanger is old and corroded, replacing it is an investment in your engine’s future and your own peace of mind.

Go take a look at your heat exchanger this weekend. Get familiar with it. Check the hoses. Put a note in your calendar to check the anodes. A little attention now ensures you’re enjoying your time on the water, not waiting for a tow.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified. I’ve performed hundreds of boat heat exchanger repairs and replacements on everything from small Yanmars to massive CATs. From Dinner Key to Bahia Mar, I keep engines cool and boaters happy.

Leave a Reply