Boat Upholstery Repair: 15 Years of Fixes, Fumbles, and Lessons Learned

I’ve been fixing boat interiors in South Florida for 15 years, from Miami’s Dinner Key Marina to Fort Lauderdale’s Bahia Mar. Boat upholstery repair isn’t just about looks—it’s about keeping your vessel comfortable and valuable despite the sun, salt, and humidity. Last June, a buddy named Carlos brought his 2021 Sea Ray 230 to my shop in Coconut Grove, cursing a cracked vinyl seat that let water soak the foam. I fixed it for $120 with a patch kit, but I’ve seen plenty of jobs spiral into $1,500 nightmares from neglect. Here’s my no-nonsense guide to tackling boat upholstery repair, whether you’re patching a tear, reupholstering a bench, or knowing when to call a pro.

Table of Contents

Why Does Boat Upholstery Fail in South Florida?

South Florida’s brutal sun and humidity chew up boat interiors faster than you’d think. I’ve seen UV-resistant thread rot in a single season if it’s not top-grade. Last summer, a client at Key Biscayne had a Grady-White 208 with blown seams—$800 to fix because water had ruined the foam. Boat upholstery repair starts with understanding why things break: UV rays degrade vinyl, saltwater corrodes staples, and moisture rots foam or backer boards. A quick inspection can save you from bigger headaches.

How Do I Assess Upholstery Damage?

A 10-minute inspection is your first step in boat upholstery repair. I grab a flashlight and check every seat on a boat. Press the cushions—mushy foam means it’s shot. Feel the backer board; if it’s soft, it’s rotting. Last July, Maria at Stiltsville ignored a cracked vinyl cover on her Boston Whaler, and the soggy foam cost her $600 to replace. Look for nicks, blown seams, or cracks—small issues let water in, turning a $50 fix into a full reupholstery job.

Types of Damage I See Most

- Cracks and Tears: Small cuts let water seep into foam, starting a chain reaction of damage.

- Blown Seams: UV exposure breaks down thread, splitting seams even if the vinyl’s fine.

- Foam Failure: Soggy or flat cushions mean the foam’s degraded and needs replacing.

- Rotten Backers: Soft or crumbling marine plywood demands a new board before reupholstering.

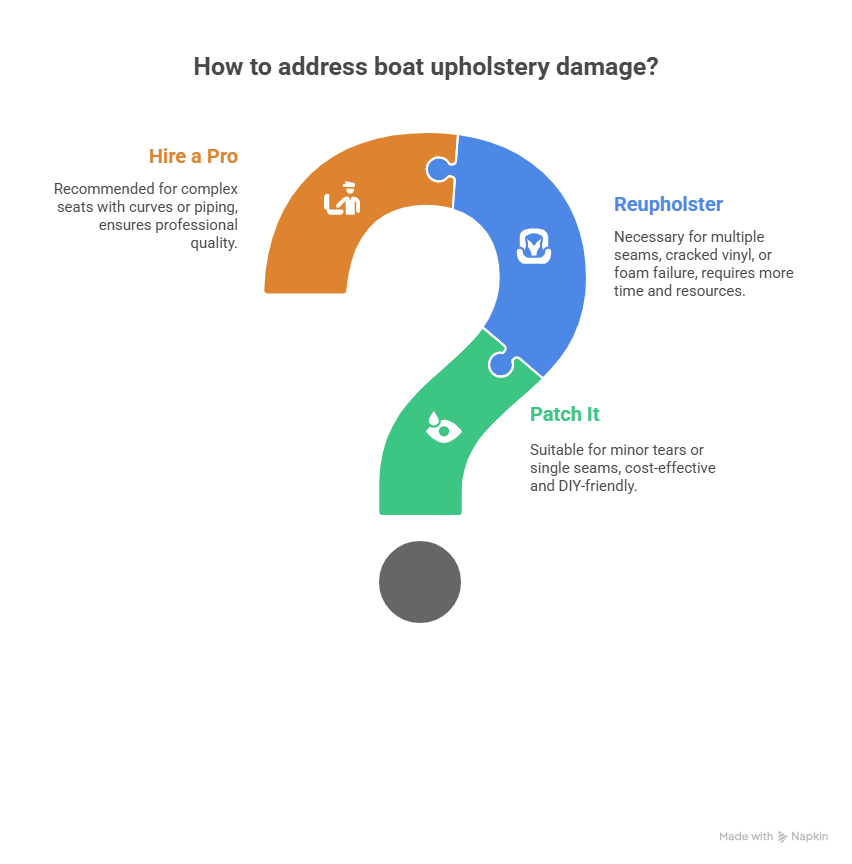

Repair, Replace, or Call a Pro?

- Patch It: Minor tears or single seams are DIY-friendly with a vinyl repair kit or Speedy Stitcher.

- Reupholster: Multiple seams, cracked vinyl, or bad foam means a full boat upholstery repair project.

- Hire a Pro: Complex seats with curves or piping need industrial sewing machines—don’t risk a botched job.

What Materials Do I Need for Boat Upholstery Repair?

Using the right materials is non-negotiable. I learned this the hard way in 2010 when I used cheap staples on a client’s Bayliner—rusted out in three months. For boat upholstery repair, always go marine-grade to beat South Florida’s elements.

Must-Have Materials

- Marine-Grade Vinyl: UV-resistant and mildew-proof, it lasts years longer than standard vinyl.

- UV-Resistant Thread: Bonded polyester thread holds up against sun exposure—standard thread rots fast.

- High-Density Marine Foam: Closed-cell foam resists water, keeping seats firm. I wrap mine in silk film for extra protection.

- Stainless or Monel Staples: Stainless is good; Monel’s better for saltwater boats. Rust is the enemy.

My Go-To Tools

- Staple Gun: A heavy-duty manual or pneumatic gun drives 3/8” staples flush into backer boards.

- Heat Gun: Makes vinyl pliable for a smooth, wrinkle-free finish on curves.

- Speedy Stitcher: Perfect for hand-sewing seams without removing covers—saved me hours on Carlos’ Sea Ray.

- Electric Carving Knife: Cuts foam cleanly for precise shaping.

- Fabric Chalk and Tape Measure: Ensures accurate templates for new vinyl panels.

I keep these in my truck for every boat upholstery repair job. Last month, I used my heat gun to stretch vinyl on a client’s contoured bucket seat at Bahia Mar—looked factory-fresh for $200.

How Do I Fix Small Tears and Blown Seams?

Not every boat upholstery repair needs a full teardown. Quick fixes can extend your seats’ life without a weekend commitment.

Patching Tears and Cracks

For small nicks, I use a color-matched vinyl repair kit—about $30 online. Last spring, a guy at Coconut Grove had a 1-inch tear on his Yamaha SX210’s helm seat. Here’s my process:

- Clean the area with isopropyl alcohol to remove grime.

- Apply the kit’s filler compound smoothly over the tear.

- Use graining paper and a heat gun to cure and texture the patch—blends almost invisibly.

This took 20 minutes and saved him $300 over replacing the panel.

Rescuing Blown Seams

Blown seams are a pain but fixable without removing the cover. I use a Speedy Stitcher with UV-resistant thread. In August 2024, a client’s Sea Ray 350 had a split seam on a lounge seat. I:

- Removed old thread with a seam ripper.

- Cleaned the seam with alcohol.

- Stitched through the original holes for a clean, strong lock stitch.

It’s not as tough as a factory seam with reinforcement tape, but it held up all season for $50.

How Do I Tackle a Full Boat Upholstery Repair?

A full reupholstery project is a game-changer for your boat’s interior. It’s a bigger commitment but doable with the right approach. I redid a client’s Pursuit 2870 in Fort Lauderdale last year—four seats, $600 in materials, and a weekend’s work.

Step 1: Tear Down and Template

Take photos and label every piece before you start. Use a staple puller to remove the old vinyl carefully—it’s your best template. I mark each panel (e.g., “Left Armrest”) and use a seam ripper to separate them. Don’t toss the old cover; it’s your roadmap.

Step 2: Rebuild the Foundation

Check the backer board. If it’s soft, cut a new one from marine-grade plywood using the old board as a template. For foam, use an electric carving knife to shape high-density marine foam. I wrap mine in silk film to block moisture—learned that after a soggy job in 2012.

Step 3: Stretch and Staple

Lay out your new vinyl and trace the old panels with fabric chalk. Drape the vinyl over the foam and board, then staple:

- One staple in the center back, pulling taut.

- One in the center front, keeping even tension.

- One on each side, forming a cross.

- Work from the center out, alternating sides to avoid wrinkles.

Use a heat gun on curves—gentle heat makes vinyl stretch smoothly. I used this on a curved bucket seat last month; took an extra 30 minutes but looked flawless.

How Much Does Boat Upholstery Repair Cost?

Boat upholstery repair costs vary based on scope and whether you DIY or hire a pro. Here’s a table from jobs I’ve seen in South Florida:

| Task | Description | Cost/Time | Tools/Materials Needed |

|---|---|---|---|

| Patch Repair | Fixing small tears or nicks | $30–$50, 20–40 min | Vinyl repair kit, heat gun |

| Seam Repair | Hand-stitching blown seams | $50–$100, 1–2 hrs | Speedy Stitcher, UV thread |

| Single Seat Reupholstery | Replacing vinyl and foam for one seat | $100–$200, 2–4 hrs | Vinyl, foam, staple gun |

| Full Boat Reupholstery | Redoing multiple seats | $500–$2,000, 8–20 hrs | Vinyl, foam, plywood, tools |

| Professional Service | Complex seats with piping or curves | $300–$800/seat | Industrial sewing machine |

DIY saves money but takes time. I spent 10 hours reupholstering a client’s four seats for $600. A pro quoted $2,400 for the same job—worth it if you’re short on time or tools.

When Should I Call a Professional for Boat Upholstery Repair?

Some jobs are too tricky for DIY. Complex seats with piping or deep curves need industrial sewing machines—my home machine failed on a bucket seat job in 2015. If you’re at a marina like Bahia Mar and lack space or time, a pro’s worth the cost. Ask for ABYC certifications and photos of past work. I walked away from a shop once that couldn’t show me a single finished seat.

FAQ: Common Boat Upholstery Repair Questions

How Often Should I Inspect My Boat’s Upholstery?

Check seats every 6 months, especially in South Florida’s humidity. Press cushions and inspect seams for cracks or rot. I caught a rotting backer on a client’s Sea Ray last July, saving $500 by replacing it early. Use a flashlight for hidden damage.

Can I Use Regular Vinyl for Boat Upholstery Repair?

No way—regular vinyl fades and cracks in months. Marine-grade vinyl resists UV and mildew. I learned this after a $200 job failed in 2011. Spend $30/yard on quality vinyl for a lasting fix.

How Do I Fix a Blown Seam Without a Sewing Machine?

Use a Speedy Stitcher with UV-resistant thread. Follow the original stitch holes for a clean lock stitch. I fixed a client’s lounge seat in 40 minutes last August—cost $50 and held all season.

What’s the Best Way to Clean Boat Upholstery Before Repair?

Use isopropyl alcohol to remove dirt and oils. I wipe down every seat before patching—did this for a Yamaha SX210 last spring. Avoid harsh cleaners; they damage vinyl.

How Do I Know If My Seat Foam Needs Replacing?

Press hard on the cushion. If it’s mushy or doesn’t bounce back, it’s done. I replaced foam on a Grady-White for $150 after it bottomed out—client said it felt brand-new.

Why Do My Seat Staples Keep Rusting?

Cheap staples rust in saltwater. Use stainless steel or Monel staples—Monel’s best for Miami’s conditions. I switched to Monel in 2013 after rust stains ruined a $300 job.

When Is Boat Upholstery Repair Too Complex for DIY?

Call a pro for seats with piping, multiple panels, or deep curves. I tried a bucket seat myself once—wasted $200 before hiring a shop with an industrial machine. Check Yelp for local pros like Miami Marine Upholstery.

Conclusion

Boat upholstery repair is about more than looks—it’s about keeping your boat comfortable and valuable. Whether you’re patching a tear or reupholstering a bench, a smart approach saves time and money. Inspect your seats, use marine-grade materials, and know when to call a pro. I’ve seen too many owners at Dinner Key regret skipping a $50 fix that became a $1,500 job. Grab a flashlight, check your seats, and get back on the water in style.

Author Bio

I’m Alex, a 15-year marine technician specializing in boat upholstery repair, based in Miami. I’ve redone interiors for 200+ boats, from Sea Rays to Boston Whalers, with ABYC certification since 2010.

Leave a Reply