I’ll never forget the call I got a few summers ago. A guy named Ray was stranded 10 miles off Key Biscayne. His engine had just died. No sputtering, no warning, just silence. He’d spent an hour guessing—was it the fuel? The battery? By the time I got to him, he was frustrated and ready to sell the boat.

The problem? A single, corroded wire on the ignition coil that had finally given up. It took me 10 minutes to spot it because I knew what to look for. Ray had the right idea, but he was missing a system. That day taught me that the most valuable tool on any boat isn’t a wrench; it’s a solid understanding of diagnostic techniques for marine engines.

For the last 15 years, I’ve been the guy people call when things go wrong on the water in South Florida. I’ve seen it all, from simple fixes to catastrophic failures. And I can tell you this: most major disasters start as small, ignored whispers. Learning to listen to your engine and knowing how to investigate problems logically is the key to safe, worry-free boating.

This isn’t going to be a technical manual. This is a real-world guide from a guy who spends his days in bilges and engine rooms. I’m going to share the practical diagnostic techniques for marine engines that I use every day to turn mysteries into solutions.

Table of Contents

The Foundation: Your Eyes, Ears, and a Bit of Logic

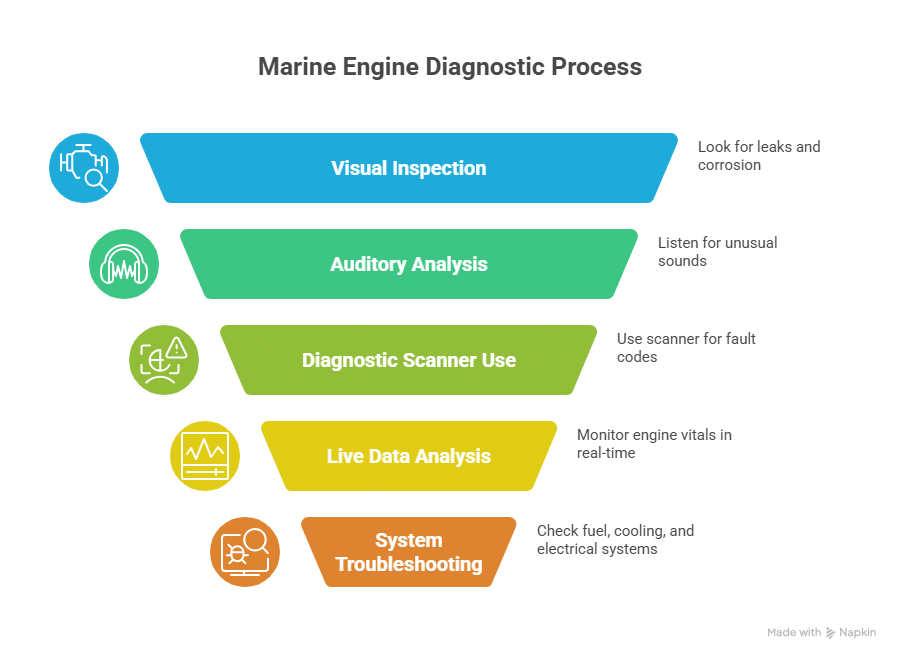

Before you even think about plugging in a fancy scanner, your most powerful diagnostic tools are the ones you were born with. A surprising number of problems can be spotted just by paying attention.

I always start a job with a simple walk-around. I’m looking for the obvious stuff:

- Visuals: Are there any leaks (oil, coolant, fuel)? Do the belts look cracked or shiny? Are the battery terminals fuzzy with corrosion? I once solved an overheating issue because I spotted a plastic bag sucked up against the raw water intake. Simple stuff.

- Sounds: An engine has a language. A high-pitched squeal is usually a belt. A deep knocking sound is bad news, likely internal. A hiss could be a vacuum leak. You learn to connect sounds to systems.

Once you spot something wrong, don’t just start replacing parts. That’s the most expensive way to fix a boat. Use a process of elimination. If the engine won’t start, what are the three things it needs? Fuel, spark, and air. Is the fuel tank full? Is the primer bulb firm? Is there a spark at the plug? These are basic diagnostic techniques for marine engines that solve half the problems out there.

The Modern Age: Letting the Engine Talk to You

Okay, the old-school methods are great, but modern engines have a huge advantage: they have a brain. The Electronic Control Module (ECM) is constantly monitoring everything. Tapping into it is one of the most powerful diagnostic techniques for marine engines we have today.

You’ll need a marine diagnostic scanner for this. It’s like an OBD-II reader for your car, but for your boat. You plug it in, and it gives you fault codes. These codes are your roadmap. A “Cylinder 3 Misfire” code tells you exactly where to start looking. It’s a huge time-saver.

But don’t just rely on the codes. The real magic is in the live data. I can watch the engine’s vitals in real-time—coolant temp, oil pressure, RPMs. If I see one cylinder running hotter than the others, I know I’ve got a problem there. For tricky issues, I’ll take the boat for a sea trial with the scanner running. When the problem happens, I can see exactly what the engine was doing at that moment.

System-by-System Troubleshooting

Most issues fall into a few key areas. Here’s a quick rundown of my approach to these common diagnostic techniques for marine engines.

| System | Common Symptoms | My First Steps |

|---|---|---|

| Fuel System | Won’t start, stalls, loses power | Check fuel quality, inspect filter for water, verify fuel pump pressure. |

| Cooling System | Overheating alarm, steam | Check raw water intake for blockages, inspect impeller, test thermostat. |

| Electrical System | No power, won’t crank, dim lights | Test battery voltage and load, inspect all main connections for corrosion. |

| Vibration/Noise | Shaking, grinding, knocking | Inspect propeller for damage, check engine mounts, try to isolate the noise. |

A methodical approach is everything. Don’t jump from a fuel problem to an electrical one without ruling things out. Follow the evidence. The best diagnostic techniques for marine engines are about being patient and logical.

The Toolkit and Staying Safe

You don’t need a truck full of tools, but a few key items will make your life a lot easier. A good multimeter is non-negotiable for any electrical work. A compression tester and a fuel pressure gauge are also essential for serious diagnostic techniques for marine engines.

And safety first, always. Disconnect the battery before working on electrical systems. Be careful with fuel—work in a well-ventilated area and have a fire extinguisher handy. An engine room is a tight, dangerous place. Think before you wrench.

And remember, the ultimate diagnostic tool is preventative maintenance. An engine that’s well-cared-for is an engine that’s easy to diagnose. Regular oil changes, clean filters, and a healthy cooling system eliminate a hundred potential problems before they ever start. Applying these diagnostic techniques for marine engines during routine checks is the smartest move you can make.

The Big Decision: Repair, Rebuild, or Replace?

Sometimes, the diagnostics lead to bad news. A major internal failure. At this point, you have a big decision to make.

- Repair: If it’s a single failed component (like a bad water pump), a repair is usually the best bet.

- Rebuild: If you have internal wear (like low compression on all cylinders), a rebuild can give your engine a new lease on life for less than the cost of a new one. But it’s a big job.

- Replace: If the block is cracked or you’ve had a catastrophic failure, sometimes starting fresh with a new motor is the only smart move.

This is where knowing when to call a pro comes in. If you’re facing a rebuild or a complex electrical issue, don’t be a hero. A good certified mechanic has the specialized tools and experience to do the job right. Some of the most advanced diagnostic techniques for marine engines require equipment and software that are just too expensive for a DIYer.

FAQ: Questions I Get All the Time

What’s the one tool every boat owner should have and know how to use?

A multimeter. It tells you the health of your battery, if your alternator is charging, and where you have bad connections. Learning basic electrical diagnostic techniques for marine engines with a multimeter will save you endless headaches.

My engine is overheating, what are the first three things I should check?

First, check your raw water intake for a blockage. Second, check your sea strainer to see if it’s full of seaweed. Third, confirm you have water coming out of the “telltale” exhaust port. If you have no water, your impeller is likely shot.

Why does my boat’s engine seem so much more complicated than my car’s?

Because it lives in a much tougher world. It’s constantly dealing with moisture, salt, and vibration, and it often runs at high RPMs for hours. That requires specialized—and often more complex—systems to keep it reliable.

What’s the biggest mistake DIYers make?

Throwing parts at a problem without a proper diagnosis. They’ll replace all the spark plugs and coils when the real issue is a clogged fuel injector. It gets expensive fast. Good diagnostic techniques for marine engines save money.

How do I know if a mechanic is any good?

Ask for certifications (like ABYC). Look for a shop that is clean and organized. And most importantly, ask other boaters at your marina. A good mechanic’s reputation is built on the docks.

Key Takeaways: My Final Advice

Alright, let’s wrap this up. If you want to get good at figuring out what’s wrong with your boat’s engine, just remember this stuff. This is what I’ve learned over 15 years of busting my knuckles.

- Trust Your Senses: Your eyes and ears will often spot trouble before any sensor does. Look and listen every time you’re on your boat.

- Be a Detective, Not a Parts-Swapper: Follow a logical process. Start simple. Don’t jump to expensive conclusions.

- Embrace the Tech: If you have a modern engine, a diagnostic scanner is an incredibly powerful tool. Learn what the codes and data mean.

- Maintenance is the Best Diagnostic: A well-maintained engine is an honest engine. It won’t lie to you with problems caused by neglect.

- Know When to Call for Help: There is no shame in calling a pro. Knowing your own limits is one of the most important diagnostic techniques for marine engines you can learn.

Author Bio

I’m Alex, a 15-year marine technician in South Florida with ABYC certifications. I live and breathe this stuff. My specialty is applying advanced diagnostic techniques for marine engines to solve complex fuel, electrical, and mechanical problems. From vintage diesels to modern outboards, I’ve diagnosed them all at marinas from Fort Lauderdale to the Keys, helping boaters stay safe and confident on the water.

Leave a Reply