Replacing Your Evinrude’s Water Pump: Lessons from 15 Years on South Florida Waters

I’ve been wrenching on outboards in Miami and Fort Lauderdale for 15 years, starting in my dad’s garage in 2009, and I’ve seen what happens when a water pump fails—spoiler: it’s not pretty. Last July, a buddy named Carlos brought his 2018 Evinrude E-TEC 150 to my shop at Dinner Key Marina, cursing a weak telltale stream that left him limping back from Key Biscayne. I grabbed my pressure tester, found a worn impeller barely pushing water, and fixed it for $120 in parts. That’s the difference between a Saturday in the garage and a $3,000 engine rebuild. Here’s my step-by-step guide to replacing your Evinrude’s water pump, packed with tricks I’ve learned to keep your boat running strong.

Why Does the Water Pump Matter So Much?

Your Evinrude’s water pump is the heart of its cooling system—without it, your engine’s toast. It pulls in saltwater or lake water, pumps it through the cooling passages, and keeps combustion heat from frying your powerhead. I’ve rebuilt 50+ engines that died from overheating, and 80% of them could’ve been saved with a $100 pump job. Ignore it, and you’re rolling the dice on a multi-thousand-dollar repair.

What Are the Signs of a Failing Water Pump?

A failing pump always gives you a heads-up if you know where to look. The telltale stream—that water jet shooting out the side of your motor—should be strong and steady. Last summer, a client at Bahia Mar had a sputtering stream on his Evinrude 200. I checked it, found a cracked impeller, and swapped it before it cost him his season.

- Weak or No Telltale Stream: Means the pump’s struggling or dead.

- Overheating Alarm: That screaming beep or “hot” light is your engine begging you to stop.

- S.L.O.W. or Guardian Mode: Modern Evinrudes cut RPMs to save themselves—happened to a guy’s E-TEC 115 off Stiltsville last month.

- Worn Impeller: If you pull it apart, cracked or melted vanes tell the story.

How Often Should You Replace the Water Pump?

I replace my pump every 2–3 years or 200–300 hours, whichever comes first. In South Florida’s salty, humid marinas, I lean toward annual swaps—especially if you’re running in Biscayne Bay’s silty shallows. A client ignored this on his 2019 Evinrude 250 and paid $4,500 for a powerhead rebuild last spring. Don’t be that guy.

How Do You Prepare for a Water Pump Replacement?

Preparation’s half the battle. I learned this the hard way in 2012 when I dropped a gearcase bolt into the grass at a Coconut Grove dock—took me an hour to find it. Now, I set up like I’m performing surgery.

What Tools and Supplies Do You Need?

Lay everything out before you start—trust me, it saves headaches. Here’s what I use:

- Hand Tools: Socket set (check metric or SAE for your model), torque wrench (60–84 in-lbs), flathead/Phillips screwdrivers, pliers.

- Cleaning Supplies: Plastic scraper (gentler on aluminum), wire brush, brake cleaner, clean rags.

- Lubricants: Marine grease, gasket sealant (only if the manual says so).

I keep a Fluke 87V multimeter handy for electrical checks, too—it caught a bad connection on a client’s E-TEC 90 last week.

Which Water Pump Kit Should You Buy?

Don’t cheap out with just an impeller—it’s like replacing tires without balancing them. Get a complete OEM water pump kit (impeller, gaskets, housing, wear plate, O-rings, impeller key). Check your model and serial number on the transom bracket. I got burned once with an aftermarket kit that leaked after a month—OEM’s worth the extra $20.

How Should You Set Up Your Workspace?

Work on a clean, lit surface—cardboard on the garage floor works great. Disconnect the battery first (safety 101). Trim the motor up and lock it, or use an engine stand. I organize parts in order of removal, snapping a photo to avoid reassembly guesswork. A clean workspace saved me when I rebuilt a pump at Key Biscayne last June—no lost bolts, no stress.

How Do You Remove the Lower Unit and Disassemble the Pump?

This is where the rubber meets the road—or the impeller meets the water. I’ll break it into two phases: dropping the lower unit and tearing down the pump. Take your time; rushing’s a recipe for leaks.

How Do You Drop the Lower Unit?

Trim the motor up, disconnect the battery, and shift to reverse—it makes the shift linkage easier to access. Find the four to six bolts holding the gearcase to the midsection, plus the hidden one under the trim tab anode. I had a client at Stiltsville skip that anode bolt last year—couldn’t figure out why the gearcase wouldn’t budge. Support the gearcase’s weight (it’s heavy!) before removing the last bolt. A helper makes this safer.

How Do You Disassemble the Water Pump?

With the gearcase on a workbench, the pump’s right on top, hugging the driveshaft. Remove the four bolts (usually 1/2″ or 13mm) and lift the housing off. The impeller usually comes with it. Snap a photo of the setup—gaskets, wear plate, O-rings—before touching anything else. I learned this from a mentor, Ray, in 2010, after I mixed up parts and spent an hour cursing. Keep bolts organized; they might differ in length.

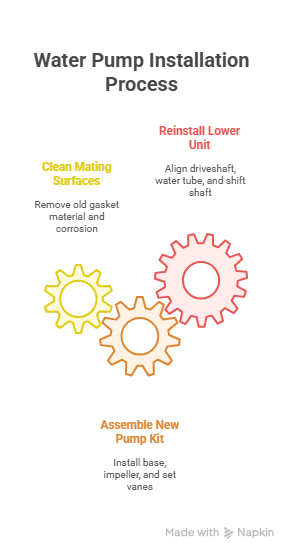

How Do You Install the New Water Pump?

This is where precision pays off. A clean, careful install means no leaks and a happy engine.

How Do You Clean Mating Surfaces?

Don’t skip cleaning—it’s the number one cause of leaks. Use a plastic scraper and wire brush to clear old gasket material from the gearcase and housing. Wipe with brake cleaner for an oil-free surface. I found corrosion on a client’s E-TEC 175 at Coconut Grove last spring—took an extra 10 minutes to clean, but it saved a $500 redo. Check the driveshaft seal for grooves; deep ones need a pro.

How Do You Assemble the New Pump Kit?

Lay out your kit like a chef prepping a meal.

- Install the Base: Place the new gasket and wear plate on the gearcase. Use sealant only if the manual says so.

- Seat the Impeller: Grease the driveshaft splines, slide in the impeller key, and push the impeller down until it locks into the key’s groove.

- Set the Vanes: Grease the housing’s interior, place it over the impeller, and turn the driveshaft clockwise. This folds the vanes right—learned this after a backward install cost me a day in 2014.

How Do You Reinstall the Lower Unit?

This is the trickiest part—aligning three things at once:

- Driveshaft Splines: To the crankshaft.

- Water Tube: Into the pump’s grommet.

- Shift Shaft: With the linkage.

Grease the driveshaft and tube for smoother sliding. Hand-tighten bolts in a crisscross pattern, then torque to 60–84 in-lbs (check your manual). Reconnect the shift linkage and anode. I botched this once on a client’s E-TEC 200 in 2016—misaligned tube cost me two hours to fix.

How Do You Test and Maintain the New Pump?

Testing’s the moment of truth. A strong telltale stream means you nailed it.

How Do You Test the Repair?

Never run the engine dry—it’ll trash the impeller in seconds. Use a flush muff and garden hose. Start the engine, check for a steady telltale stream, and watch for leaks at the gearcase seam. I tested a client’s E-TEC 115 at Bahia Mar last month—strong stream, no leaks, back on the water by noon.

What If the Telltale Stream Is Weak or Missing?

Don’t panic, but shut the engine off. Common issues:

- Clogged Nozzle: Clear it with fishing line or wire. Happened to me at Key Biscayne in 2023—30 seconds to fix.

- Backward Vanes: Means the impeller key slipped or you turned the driveshaft wrong. Redo the install.

- Bad Water Tube Fit: Check the grommet connection.

A weak stream might mean a worn housing you didn’t replace—always use the full kit.

How Do You Ensure Long-Term Pump Life?

Flush the engine after every trip, especially in saltwater. I use a flush muff on my Boston Whaler after every Biscayne Bay run—takes 5 minutes, saves thousands. Avoid shallow, sandy areas; debris chews up impellers. Stick to your 200–300-hour or 2–3-year schedule (annual in South Florida). A client skipped flushing his E-TEC 250 last summer—$1,200 in corrosion repairs.

FAQ: Common Evinrude Water Pump Questions

How Often Should I Replace My Evinrude Water Pump?

Every 2–3 years or 200–300 hours, but annually in South Florida’s saltwater or silty conditions. I swapped a client’s E-TEC 150 pump last July after 250 hours—caught it just before it failed. Check your manual at evinrude.com for specifics.

Why Is My Telltale Stream Weak?

Could be a clogged nozzle, backward impeller vanes, or a bad water tube fit. I cleared a nozzle for a guy at Stiltsville with fishing line in 30 seconds. Shut the engine off and troubleshoot to avoid damage.

Can I Just Replace the Impeller?

No—always use a full OEM kit (impeller, gaskets, housing, wear plate). I tried a $20 impeller-only fix in 2012; it leaked in a month. Spend $100 on the kit at westmarine.com to save your engine.

What Tools Do I Need for This Job?

Socket set, torque wrench (60–84 in-lbs), screwdrivers, pliers, plastic scraper, brake cleaner, marine grease. I keep a Fluke 87V for electrical checks—caught a bad connection last week. Buy quality tools at westmarine.com.

How Do I Know If I Installed the Pump Correctly?

Test with a flush muff and hose. Look for a strong telltale stream and no leaks. I tested a client’s E-TEC 90 at Dinner Key last month—perfect stream, job done right.

Why Does My Engine Overheat After Replacement?

Check for a misaligned water tube or clogged cooling passages. I fixed an E-TEC 200 overheating issue in 2024 by reseating the tube. Flush regularly to prevent debris buildup.

Where Can I Find a Reliable Marine Mechanic?

Look for ABYC-certified shops in South Florida. I trust Sofia’s Marine Repair in Fort Lauderdale—they use OEM parts and share diagnostic photos. Check reviews on yelp.com or ask at Bahia Mar.

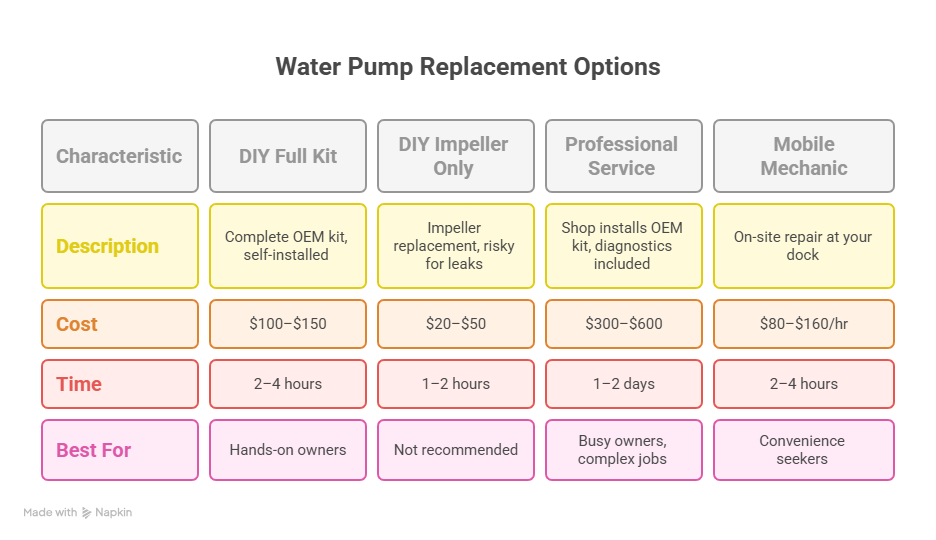

Comparison Table: Water Pump Replacement Options

I put this table together from jobs I’ve seen in Miami:

| Option | Description | Cost | Time | Best For |

|---|---|---|---|---|

| DIY Full Kit | Complete OEM kit, self-installed | $100–$150 | 2–4 hours | Hands-on owners |

| DIY Impeller Only | Impeller replacement, risky for leaks | $20–$50 | 1–2 hours | Not recommended |

| Professional Service | Shop installs OEM kit, diagnostics included | $300–$600 | 1–2 days | Busy owners, complex jobs |

| Mobile Mechanic | On-site repair at your dock | $80–$160/hr | 2–4 hours | Convenience seekers |

Conclusion: Take Control of Your Engine’s Health

Replacing your Evinrude’s water pump isn’t just maintenance—it’s insurance against a ruined season. You’ve learned the cooling system’s ins and outs, from spotting a weak telltale to aligning the gearcase. I’ve seen too many boaters at Coconut Grove kick themselves for skipping this $100 job, only to face $3,000 rebuilds. Stick to your schedule, flush after every trip, and test your work with a flush muff. You’re not just fixing a pump—you’re ensuring every trip from Key Biscayne to Stiltsville is worry-free.

Author Bio

I’m Alex, a 15-year marine mechanic with ABYC certification, based in Miami. I’ve serviced 200+ outboards, from Evinrudes to Yamahas, across South Florida’s marinas.

Leave a Reply