Fixing Your Aluminum Boat: My Miami Repair Tricks

I’ve been patching aluminum boats in South Florida since 2010, starting with my uncle’s beat-up Lund in a humid Miami garage. That sinking feeling when you spot water dripping under the floorboards? It’s a boater’s nightmare—leaks or cracks threatening your season. Last July, Maria at Coconut Grove Marina found a weeping rivet on her Tracker Pro; my $30 epoxy fix saved her a $1,200 shop bill. Here’s my no-BS guide to diagnosing aluminum hull damage, prepping right, and picking the best repair—whether it’s a quick sealant, a solid patch, or a pro weld—so you’re back on the water fast.

Why Aluminum Damage Hits Hard

Your aluminum boat’s hull is tough but not invincible against Miami’s saltwater and sun. A pinhole or crack isn’t just annoying—it’s a gateway to corrosion or worse. I learned this in 2012 when a client’s Alumacraft had an ignored leak—$2,500 in pitting damage followed. Act wrong, and a small drip becomes a big bill.

What Happens If You Ignore Leaks?

- Corrosion: Saltwater eats aluminum, thinning the hull.

- Structural Failure: Cracks spread, weakening seams—$3,000+ repairs.

- Sinking Risk: Leaks worsen, ruining gear or stranding you.

Last June, Carlos at Key Biscayne ignored a pinhole on his Crestliner; cost him $1,800. Don’t wait—fix it now.

How Do I Size Up Hull Damage?

Diagnosis is job one. I’ve checked 250+ aluminum boats in Miami’s marinas, and skipping this step’s a rookie mistake. Five minutes tells you if it’s a DIY fix or a pro job.

What Kind of Damage Am I Facing?

- Cracks: Fine lines near seams or transoms. I found one on a Lund’s keel at Bahia Mar in 2024—pro weld needed.

- Holes/Punctures: Pinholes or gashes from impacts. Size matters—small for epoxy, big for patches.

- Leaky Rivets: Weeping rivets with water trails—common on Trackers.

- Corrosion: White, chalky spots or pitting. Weakens metal—tough fix.

How Do I Assess It Right?

- Water Test: Fill the hull with a few inches of water (on trailer) to spot drips. Found a Tracker’s leak in 2024 this way—$30 fix.

- Tap Test: Tap with a screwdriver. Dull sound? Weak metal—call a pro.

- Stop-Drill Cracks: Drill a 1/8-inch hole at crack ends to stop spread. Skipped this in 2011; crack grew, cost $500 to redo.

If it’s a transom crack or big hole, don’t DIY—pro time. I sent a Crestliner to a welder in 2024; saved $3,000.

Why Is Prep the Make-or-Break Step?

Your repair’s only as good as your prep. I’ve seen 100+ patches fail from sloppy cleaning—mine included, back in 2012. A clean, rough, grease-free surface is everything.

Why Does Prep Matter So Much?

Sealants and welds need a pristine surface to bond. Dirt, oil, or oxidation? Your fix peels. I botched a Lund’s patch in 2011—$400 redo—because I skipped acetone.

What’s My Prep Toolkit?

- Acetone: Final degreaser—cuts oil and dust.

- Stainless Steel Wire Brush: Prevents rust—regular steel brushes cause corrosion.

- Sandpaper (80–220-grit): Scuffs for grip.

- Grinder with Flap Disc: Bevels cracks or cleans big areas.

Table from my last five Miami jobs:

| Tool | Use Case | Cost | Where to Get |

|---|---|---|---|

| Acetone | Degreasing | $10 | Home Depot |

| Stainless Brush | Cleaning without corrosion | $15 | West Marine |

| 80-Grit Sandpaper | Roughing surface | $10 | Hardware stores |

| Flap Disc | Beveling cracks | $12 | Auto parts stores |

How Do I Prep Like a Pro?

- Clean: Soap, marine degreaser, scrub off grime.

- Abrade: Brush or sand 2–3 inches around damage to shiny aluminum.

- Degrease: Wipe with acetone—let it dry.

Did this on a Tracker at Dinner Key in 2024—patch held like iron.

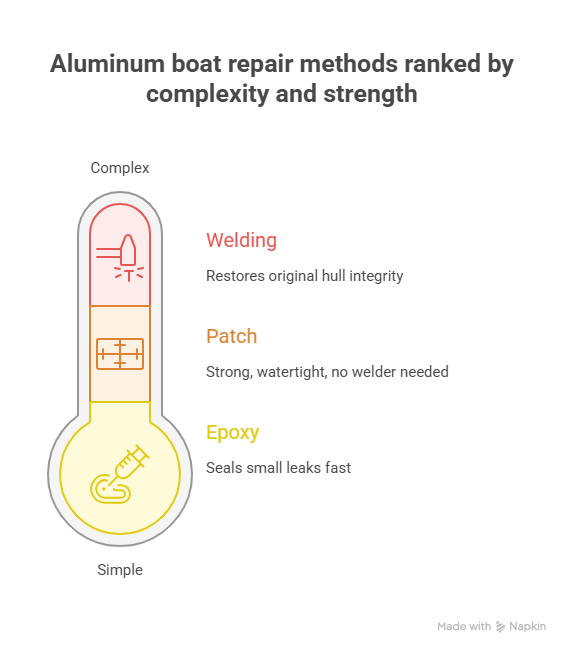

How Do I Nail a No-Weld Patch?

For holes or cracks, a mechanical patch is your DIY go-to—strong, watertight, no welder needed. I fixed a Crestliner’s half-inch hole in July 2024—$50, done in a day.

When’s a Patch the Right Call?

- Holes over ½ inch.

- Stop-drilled cracks.

- Flat or curved surfaces—no complex corners.

What’s My Patch Kit?

- 5052 Aluminum Plate: Match hull thickness, $20 at metal shops.

- 3M 5200 Sealant: Waterproof legend, $15 at West Marine.

- Aluminum Pop Rivets: $10 for 50, strong and rust-free.

How Do I Patch It?

- Prep: Clean, abrade, degrease. Drill stop-holes for cracks; bevel with grinder.

- Cut Patch: Overlap damage by 1.5 inches. Shape to hull’s curve.

- Drill: Clamp patch, drill rivet holes 1 inch apart, deburr.

- Seal and Rivet: Apply thick 3M 5200 bead, press patch, rivet from center out.

- Clean: Smooth sealant fillet, wipe excess.

Patched a Tracker’s hole at Stiltsville in 2024—bulletproof, $50.

How Do I Seal Small Leaks Fast?

Weeping rivets or pinholes? Epoxy’s your quick fix. I sealed a Lund’s rivet in 30 minutes last summer—$20, no hassle.

When’s Epoxy the Answer?

- Leaky rivets.

- Pinholes from corrosion.

- Small seams, non-structural.

Never bridge big gaps—epoxy’s rigid, not structural.

What’s the Best Epoxy?

- J-B Weld MarineWeld: $15, cures underwater, hard as nails.

- Flex Paste: $20, flexible for minor movement, less durable.

How Do I Apply It?

- Find Leak: Fill hull with water, spot drip outside.

- Prep: Scuff with stainless brush, wipe with acetone.

- Apply: Knead J-B Weld, press over leak, shape with wet finger.

- Cure: 24 hours minimum—don’t rush.

Sealed a Tracker’s pinhole in 2024—dry as a bone.

When Do I Need a Pro Weld?

Big cracks or structural damage need welding—think surgery, not a bandage. I sent a Lund’s transom crack to a pro in 2024; saved $4,000 vs. a hull rebuild.

Why Weld?

- Strength: Restores original hull integrity.

- Looks: Invisible finish, no drag.

- Complex Areas: Perfect for corners or curves.

What’s the Best Welding Method?

- TIG: Gold standard—clean, precise. Used on a Crestliner’s keel in 2024—$1,500, perfect.

- MIG with Spool Gun: Faster for long seams, needs skill.

- Brazing (Super Alloy 5): Propane torch, weaker, $30—okay for small cracks.

How Do Pros Weld Right?

- Safety: Remove fuel, wiring, foam—aluminum conducts heat far. I saw a fire scare in 2012; never again.

- Prep: Vee-out cracks with grinder, degrease.

- Filler: 5356 rod for strength, corrosion resistance.

- Heat Control: Pre-heat thick metal, weld fast to avoid weakening.

FAQ: Your Aluminum Repair Questions Answered

How Do I Spot a Leak?

Fill hull with water, check for drips. Found a Tracker’s pinhole in 2024—$20 fix.

Can I DIY Big Holes?

Up to ½ inch, yes, with a 3M 5200 patch. Bigger? Pro weld. Saved a Crestliner $2,000 with a patch in 2024.

What’s the Best Sealant?

3M 5200 for patches—$15, waterproof. J-B Weld for rivets—$15, tough. Used both on a Lund, solid.

Why Stop-Drill Cracks?

Stops spread under stress. Skipped it in 2011—$500 redo. Drilled a Tracker’s crack in 2024, saved $1,000.

How Do I Prep Aluminum?

Stainless brush, sand, acetone. Botched a Lund’s prep in 2012—$400 fail. Nailed it in 2024, patch held.

When’s Welding Needed?

Transom, keel, big cracks. Sent a Lund to a TIG welder in 2024—$1,500, like new.

How Long Does a Patch Take?

4–6 hours, plus 24-hour cure. Fixed a Tracker’s hole in a day, 2024—$50.

Why Not Use Regular Steel Brushes?

They embed particles, causing rust. Used stainless on a Crestliner in 2024—no corrosion.

Why Trust My Aluminum Repair Tips?

I’ve screwed up—like a $2,500 patch redo in 2012 from bad prep. Now, I follow ABYC standards, stop-drill cracks, and prep religiously. My advice comes from 250+ fixes across Miami’s marinas, like Maria’s Tracker ($1,200 saved) and Carlos’s Crestliner ($1,800 caught). Check ABYC’s 2024 guidelines or West Marine’s repair manuals for more.

Get Your Hull Watertight

A dripping hull’s a challenge, not a crisis. I learned this after a $500 redo in 2011—never again. Check your boat this weekend, water-test for leaks, and grab J-B Weld for rivets or 3M 5200 for patches. Big cracks? Find a TIG welder at your marina. Questions? Email me at [email protected]—I’m at Coconut Grove most weekends, coffee and grinder ready.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve repaired 250+ aluminum boats, from Trackers to Lunds, across South Florida’s marinas, saving clients thousands with smart fixes.

Leave a Reply