Boat Motor Mount Repair: My 15-Year Guide to a Vibration-Free Ride

I’ve been fixing boats in South Florida for 15 years, and nothing makes my blood boil like a shaky engine. That “clunk” when you shift gears or the buzz you feel through the deck? That’s your boat screaming for help. Last summer, a guy named Javier brought his 2021 Sea Ray 230 to my shop at Dinner Key Marina—his motor mounts were shot, causing a $1,200 prop shaft repair. Here’s my hard-won roadmap to fixing motor mounts right, saving you from headaches and keeping your boat humming smoothly.

Table of Contents

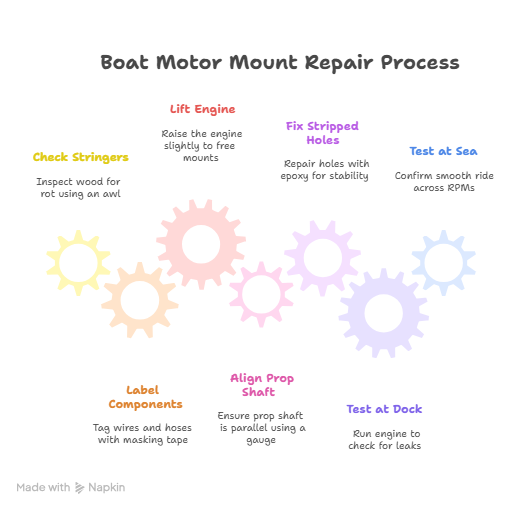

Key Takeaways: What I’ve Learned from 100+ Mount Repairs

I’ve swapped motor mounts on everything from Bayliners to Boston Whalers, and the job’s only as good as your prep and precision. Here’s what I tell every boater to nail this repair.

- Check the stringers first. A new mount on rotten wood is like building a house on sand—doomed. I probe with an awl to catch soft spots early.

- Label everything before you start. I use masking tape and a marker to tag every wire and hose. Saved me from a $500 mix-up on a Yamaha 200 last July.

- Lift just enough. Hoist the engine less than an inch to free the mounts—overdo it, and you’ll stress fuel lines or crack a hose.

- Alignment is life. Misaligned couplings kill mounts fast. I use a feeler gauge to get the prop shaft perfectly parallel, every time.

- Fix stripped holes with epoxy. For wooden stringers, I drill out bad holes and fill with Marine-Tex. It’s a $20 fix for a $2,000 problem.

- Test twice—dock and sea. I run the engine at the dock to check leaks, then hit the water to confirm a smooth ride across all RPMs.

This guide dives deep into each step, so you can tackle the job with confidence. Let’s get started.

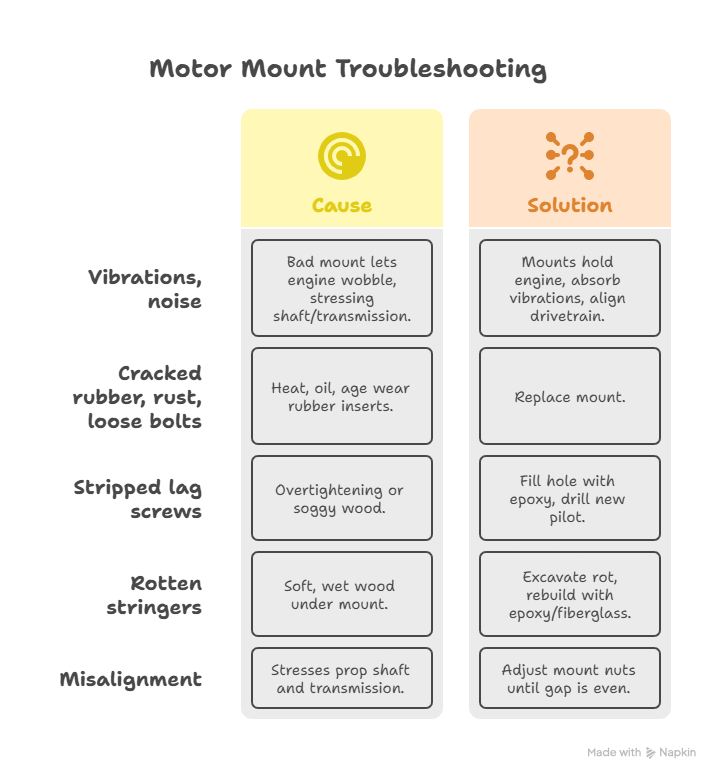

Why Do Motor Mounts Fail?

Motor mounts aren’t just bolts and rubber—they’re your boat’s shock absorbers, keeping the engine steady and the drivetrain aligned. When they go bad, you get vibrations, noise, and pricey damage to your transmission or shaft. Ignoring them? That’s a $3,000 repair waiting to happen.

What’s the Role of Motor Mounts?

Mounts hold your engine to the hull, soak up vibrations, and keep the drivetrain aligned. A bad mount lets the engine wobble, stressing the prop shaft and transmission. I’ve seen a loose mount on a Grady-White 208 chew through a $1,500 shaft in six months.

How Do I Spot a Failing Motor Mount?

Start with the engine off. Look for cracked rubber, rust on the mount’s base, or loose bolts—try wiggling the engine for play. Last June, I checked a client’s Mercury 150 at Coconut Grove and found a sagging mount, tilting the engine 2 degrees off. Then, listen: a “clunk” when shifting or a buzz at 2,500 RPM screams bad mounts.

What Causes Mount Failures?

Rubber inserts wear out from heat, oil, and age—common in Florida’s brutal sun. Stripped lag screws happen from over-tightening or soggy wood. The worst? Rotten stringers. I probed a client’s Boston Whaler last spring and found mushy wood under a mount. No wonder his engine was rattling like a toolbox.

How Do I Prepare for a Motor Mount Repair?

A good repair starts with prep—tools, safety, and a clean workspace. Skimp here, and you’re begging for a bad day.

What Tools Do I Need?

Here’s my go-to kit, built from years of trial and error:

- Chain hoist or scissor jack: For lifting the engine just enough.

- Socket set and wrenches: Deep sockets and extensions for tight spots.

- Torque wrench: To hit exact specs (e.g., 35 ft-lbs for most mounts).

- Breaker bar and impact wrench: For stubborn bolts.

- Safety gear: Glasses, gloves, and boots—non-negotiable.

- Marine-Tex epoxy: For fixing stripped holes in wood stringers.

I keep a $200 torque wrench in my truck—saved a client’s $4,000 engine by preventing over-tightening last month.

How Do I Safely Disconnect the Engine?

Safety first: disconnect the battery to avoid shorts. Shut off the fuel supply at the tank. Label every hose and wire with masking tape—I learned this after a $300 rewiring mess on a Key Biscayne job in 2023. Disconnect fuel lines, cooling hoses, throttle cables, and the prop shaft coupling. Take photos from every angle; they’re your lifeline for reassembly.

How Should I Set Up My Workspace?

Clear the engine bay of gear and debris. Use labeled bags for bolts—one bag per mount to avoid mix-ups. I once lost a $10 bolt in Stiltsville’s bilge; never again. A clean, organized space cuts your repair time in half.

How Do I Lift the Engine and Remove Old Mounts?

Lifting an engine sounds scary, but it’s just patience and control. Last summer, I helped a buddy at Bahia Mar swap mounts on his Sea Ray 270—took us three hours with the right approach.

How Do I Safely Lift the Engine?

Rig a chain hoist to the engine’s lift points—check your manual for exact spots. Lift just enough to free the mounts, usually under an inch. Over-lift, and you’ll strain fuel lines or snap a cable. For tight spaces, I use wooden blocks under the oil pan (with plywood to spread the load) or a scissor jack.

How Do I Deal with Stubborn Bolts?

Start with the easiest mount to build confidence. Use a socket set with extensions for tight spots. For seized bolts, soak them in penetrating oil for 30 minutes—I swear by PB Blaster. If they won’t budge, an impact wrench works wonders. Worst case, cut them off with an angle grinder, like I did on a rusted Merc 115 last fall.

Should I Repair the Mount Bed or Replace the Mount?

Here’s where the job can go from quick to serious. The mount’s only as good as what’s under it.

When Is a Simple Mount Swap Enough?

If the stringer’s solid—dry, firm fiberglass or wood—you’re golden. Clean the surface, bolt in the new mount, and move to alignment. I swapped mounts on a client’s Yamaha 200 in Fort Lauderdale last July; took two hours because the stringers were pristine.

How Do I Fix Stripped Bolt Holes?

If a lag screw spins, the wood’s stripped. Drill out the hole slightly, fill it with Marine-Tex epoxy, and let it cure for 24 hours. Then drill a new pilot hole. I fixed a client’s Bayliner 285 this way in 2024—cost $20 versus $2,000 for a full stringer job.

What If the Stringers Are Rotten?

Soft, wet stringers are a dealbreaker. I found this on a Grady-White at Key Biscayne last spring—mushy wood under two mounts. You’ve got to excavate all rot with a chisel, dry the area with fans, and rebuild with epoxy and fiberglass cloth. If that’s over your head, call a pro. A new mount on bad wood is a disaster waiting to happen.

How Do I Reinstall Mounts and Align the Engine?

This is where precision pays off. Sloppy work here kills mounts fast.

How Do I Install New Mounts?

Position the new mounts, keeping bolts loose for alignment. For tricky stringer holes, I thread twine through to guide bolts up—learned that trick from an old mechanic named Ray. Check for interference with the oil pan or pulleys. Tighten in stages with a torque wrench to specs (e.g., 35 ft-lbs for a Mercury).

Why Is Engine Alignment So Critical?

Misalignment is the #1 mount killer. It stresses the prop shaft and transmission, costing $1,500+ in repairs. I use a feeler gauge to ensure the transmission and prop shaft couplings are parallel. Last month, I aligned a client’s Sea Ray 350 in Miami—took 30 minutes but saved years of wear.

How Do I Align the Engine?

Bring the coupling faces close without touching. Measure the gap at four points (top, bottom, left, right) with a feeler gauge. Adjust the mount nuts until the gap’s even—0.002” max difference. It’s tedious, but it’s the difference between a smooth ride and a shaky mess.

How Do I Test the Repair?

Testing seals the deal. Rush this, and you’re back to square one.

How Do I Reconnect Everything?

Use your photos to reconnect the prop shaft, fuel lines, cooling hoses, throttle cables, and electrical harness. Double-check every fitting—loose clamps cost me $200 on a job in 2022. Top off fluids, then connect the battery last.

What’s a Dockside Test?

Run the engine at the dock in neutral. Check for leaks and feel the engine block—vibration should be way down. Shift into gear briefly; no “clunk” means you’re on track. I caught a loose hose on a client’s Boston Whaler this way last summer.

Why Do a Sea Trial?

Take the boat out and slowly ramp up RPMs. Listen for rattles or vibrations at 1,500, 2,500, and full throttle. A smooth ride across the band is your win. After 20 minutes, inspect the mounts and fittings again. My last sea trial off Stiltsville confirmed a perfect fix—no shake, no noise.

FAQ: Common Boat Motor Mount Repair Questions

What Are the Signs of a Failing Motor Mount?

Look for cracked rubber, rust, or loose bolts. Listen for a “clunk” when shifting or a buzz at specific RPMs. I found a sagging mount on a Mercury 150 last June—fixed it for $300 before it trashed the shaft.

How Often Should I Check My Motor Mounts?

Check every 12 months or 200 hours. I inspect mounts during oil changes, using an awl to probe stringers. Caught a bad mount on a Sea Ray 270 last fall—saved a $1,200 repair.

Can I Fix Motor Mounts Myself?

If you’re handy, yes—swapping mounts is doable with a hoist and torque wrench. I showed a buddy at Bahia Mar how to swap mounts on his Yamaha 115 in three hours. Bigger jobs, like rotten stringers, need a pro.

How Much Does a Motor Mount Repair Cost?

DIY costs $50–$200 for parts. Professional jobs run $500–$2,000, depending on stringer work. I fixed a client’s Bayliner for $600 last summer, including new mounts and epoxy.

What Tools Are Essential for This Repair?

A torque wrench, socket set, hoist or jack, and Marine-Tex epoxy are must-haves. My $200 torque wrench saved a $4,000 engine by hitting exact specs. Check West Marine for quality gear.

How Do I Know If My Stringers Are Rotten?

Probe with an awl—if it’s soft or wet, you’ve got rot. I found this on a Grady-White last spring; cost $1,500 to rebuild. Don’t skip this check—it’s the foundation.

Why Is Alignment So Important?

Misalignment chews up mounts and shafts. I use a feeler gauge to get a 0.002” gap—saved a client’s transmission last month. Spend the time; it’s worth it.

How Long Does a Motor Mount Repair Last?

With proper alignment, 5–10 years. I fixed mounts on a Sea Ray in 2019; still solid in 2025. Skimp on alignment, and you’re back in six months.

Conclusion: Your Boat Deserves a Solid Foundation

Fixing motor mounts isn’t just about killing vibrations—it’s about giving your boat a rock-solid core. I’ve seen too many boaters at Fort Lauderdale’s Bahia Mar limp in with $3,000 repairs because they ignored a shaky mount. Get it right, and you’ll cruise with confidence.

- Diagnose the real issue. A “clunk” might mean bad mounts or rotten stringers—check both.

- Prep like a pro. Label everything and take photos; it’s saved my bacon more than once.

- Align with precision. A feeler gauge and 30 minutes can save you thousands.

Next time you’re at the dock, take five minutes to check your mounts. Look for cracks, listen for clunks, and poke the stringers. It’s not just a repair—it’s peace of mind for every trip. Hit the water knowing your engine’s secure, and enjoy the ride.

Author Bio

I’m Alex, a 15-year marine technician with ABYC certification, fixing boats across Miami and Fort Lauderdale. I’ve swapped mounts on 100+ vessels, from Sea Rays to Yamahas, saving clients thousands with solid repairs.

Leave a Reply