Marine Diesel Troubleshooting: A Specialist’s Guide to Reliability

I’ve been a marine diesel specialist for 15 years, wrenching on engines from Miami to Fort Lauderdale. Last June, a client named Javier at Dinner Key Marina called me in a panic—his 2021 Sea Ray 350 wouldn’t start, just a dead click, stranding him off Key Biscayne. A quick check with my Fluke multimeter showed a 0.5-volt drop at the starter solenoid—fixed for $200. Moments like that taught me: understanding your diesel’s core systems and partnering with a skilled marine diesel specialist can save your day on the water. This guide shares my hard-won tricks to keep your engine humming, spot trouble early, and choose a pro you can trust.

Table of Contents

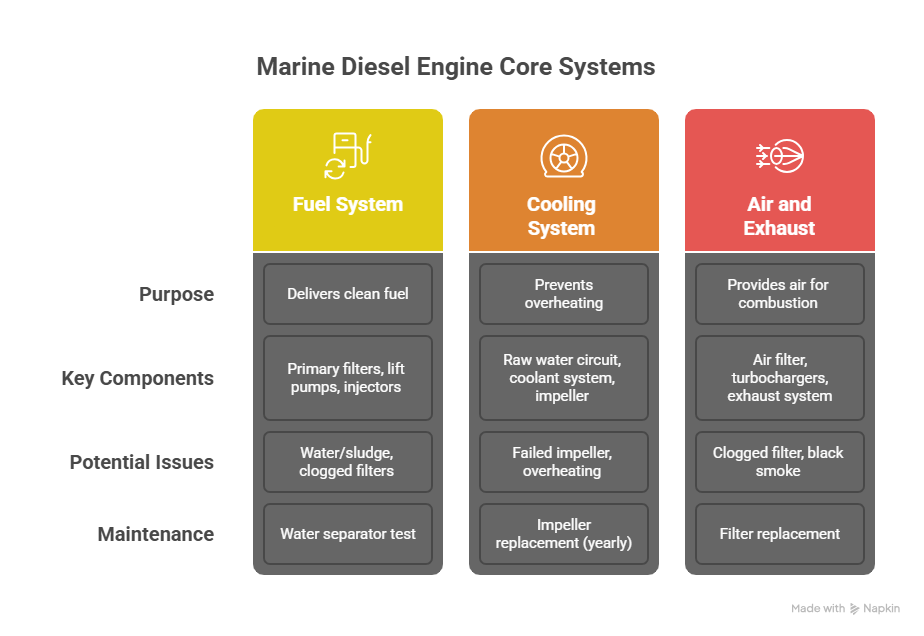

What Are the Key Systems in a Marine Diesel Engine?

Marine diesels are beasts, but they rely on three core systems: fuel, cooling, and air. Get these right, and you’re halfway to worry-free boating. I learned this back in 2009, working with my mentor Ray in a Fort Lauderdale shop, tearing down a Cummins QSB that died from a clogged fuel filter.

Fuel System: The Engine’s Lifeline

Clean fuel is non-negotiable. Diesel’s gotta flow water-free at high pressure—think 20,000 PSI for modern injectors. Water or “diesel bug” (microbial sludge) can wreck injectors costing $500 each. I always check fuel filters with a water separator test—caught a $2,000 issue for a client’s Yanmar last summer. Key parts: primary filters, lift pumps, and injectors that atomize fuel for combustion.

Cooling System: Keeping Overheating at Bay

Diesels run hot—200°F in a 90°F engine room. The raw water circuit pulls seawater to cool the exhaust and closed coolant system, which circulates antifreeze like a car’s radiator. A failed impeller (that $25 rubber part) can cook your engine in minutes. I swap impellers yearly, no exceptions—saved a buddy’s boat from a $3,000 rebuild at Stiltsville in 2023.

Air and Exhaust: The Engine’s Lungs

A diesel gulps 10,000 gallons of air per gallon of fuel. A clogged filter chokes power, spitting black smoke. I saw this on a Volvo Penta D6 at Bahia Mar last month—new filter, problem gone in 20 minutes. Turbochargers boost air intake, and the exhaust system vents hot gases, cooled by seawater to avoid fires. Know these systems, and you’ll spot issues before they strand you.

How Can a 5-Minute Check Prevent Engine Failure?

Your daily checks are your engine’s first line of defense. I learned this the hard way in 2011 when I skipped a check and got stuck off Miami with a dead fuel pump. A 5-minute walkthrough catches 80% of issues before they escalate—here’s my routine, honed over 200+ service calls.

- Visual Scan: Look for oil drips, loose belts, or corroded wires. I caught a frayed hose on a client’s Sea Ray last July—$50 fix, not $1,500.

- Fluids: Check oil, coolant, and transmission fluid. Milky oil screams water intrusion; gritty coolant means corrosion. I use a flashlight to spot this.

- Fuel Separator: Drain the water separator to check for gunk. Found water in a client’s tank at Coconut Grove in 2024—saved his injectors.

- Raw Water Flow: Start the engine and confirm a steady exhaust water stream. No flow? Check the sea strainer for seaweed. Did this for a guy at Key Biscayne last spring.

This habit takes 5 minutes but can save thousands. Pair it with a marine diesel specialist’s annual service, and you’re golden.

What Does a Marine Diesel Specialist Do Annually?

A marine diesel specialist isn’t just swapping oil—they’re your engine’s doctor. My annual services at Sofia’s Marine Repair in Fort Lauderdale go deep, catching issues your daily checks miss. Here’s what I do, based on 15 years and ABYC certification.

- Fluids and Filters: Swap engine oil (5W-30 for most diesels), coolant, and fuel filters using OEM specs. I caught a clogged filter on a Caterpillar 3126 last month—$200 job, not $5,000.

- Impeller Swap: Replace the raw water impeller yearly, no matter the hours. A $25 part prevents a $3,000 overhaul. I keep spares in my truck.

- System Checks: Inspect belts for 10mm deflection, hoses for cracks, and clean heat exchanger cores. Found a corroded exchanger on a client’s boat in 2024—fixed for $600.

- Diagnostics: Use brand-specific software (e.g., Cummins INSITE) to read fault codes. I caught a low-pressure injector issue on a Volvo Penta D4 in July 2024.

- Alignment: Check engine-transmission alignment with a feeler gauge—0.003” max deviation. Misalignment cost a client $1,200 in vibration damage last year.

These tasks reset your engine’s health, ensuring reliability. Skip them, and you’re gambling with your season.

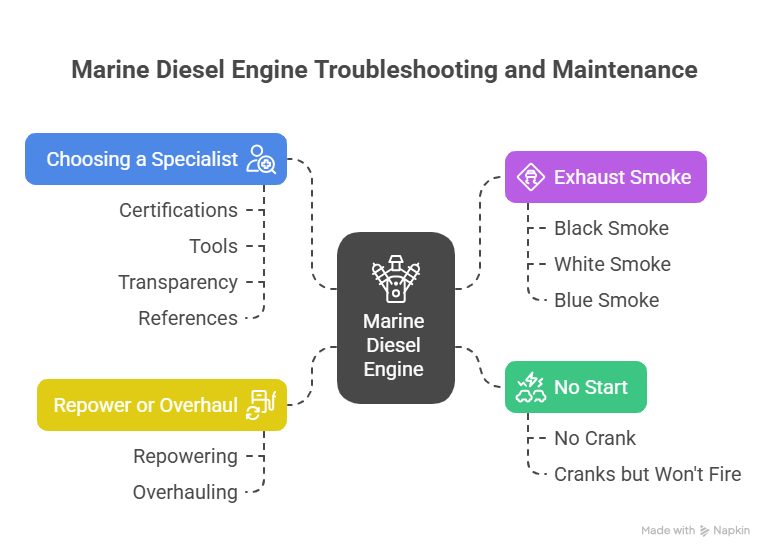

Why Won’t My Marine Diesel Start?

A no-start is a gut punch, but it’s telling you something. I’ve towed 50+ boats with start issues—here’s how to decode them, based on a case I handled at Stiltsville last summer.

No Crank, Just a Click

A dead click usually means electrical trouble. Check battery voltage (12.6V minimum) and clean terminals—corrosion’s a killer in Florida’s salt air. I fixed a no-crank on a client’s Bayliner 285 with a $50 terminal clean in 2023. If batteries are good, call a marine diesel specialist for starter or solenoid issues.

Cranks but Won’t Fire

This points to fuel. Open the fuel shut-off, bleed the system for air, and check the primary filter for water. I bled a client’s Yanmar 6LY at Key Biscayne last June—$100 fix. If that doesn’t work, a marine diesel specialist needs to test the lift pump or injectors with a pressure tester (20,000 PSI for high-pressure systems).

What Does Exhaust Smoke Tell Me?

Exhaust smoke is your engine’s health report. I learned this from Ray, who showed me how to read smoke on a Cummins QSC in 2010. Here’s what it means.

- Black Smoke: Incomplete combustion, often a clogged air filter. I swapped a filter on a client’s Sea Ray 310 last month—$30 fix, power restored.

- White Smoke: Unburnt fuel or steam, signaling injector or head gasket issues. This needs a marine diesel specialist with diagnostic software.

- Blue Smoke: Burning oil, likely worn piston rings. I saw this on a Volvo Penta at Bahia Mar in 2024—$4,000 overhaul needed.

Spot smoke early, and you’ll save thousands. A marine diesel specialist can confirm the root cause with a compression test (400–500 PSI for most diesels).

When Should I Consider a Repower or Overhaul?

Sometimes, your engine needs more than a tune-up. I’ve done 20 repowers and 30 overhauls, and they’re game-changers when done right.

Repowering: A New Heart

Repowering swaps your old engine for a modern one—think better fuel efficiency (30% gains on new Yanmars) and reliability. I repowered a client’s Boston Whaler with a Cummins QSB5.9 in 2023—$15,000 job, but it cut fuel costs by $2,000 a year. A marine diesel specialist ensures engine beds, props, and exhaust align perfectly.

Overhauling: Rebuilding the Core

An overhaul rebuilds your engine to factory specs—ideal for persistent issues like oil consumption (1 quart per 10 hours) or low compression (below 350 PSI). I overhauled a Caterpillar 3208 for a client at Coconut Grove last year—$8,000 versus $20,000 for a repower. It involves disassembling, machining, and replacing wear parts like bearings.

Both need a marine diesel specialist with brand-specific tools and experience. Don’t skimp here—it’s a big investment.

How Do I Choose a Reliable Marine Diesel Specialist?

Picking a marine diesel specialist is like choosing a surgeon for your boat. I’ve seen too many botched jobs at Bahia Mar—here’s how to find a pro.

- Certifications: Look for Yanmar, Cummins, or Volvo Penta certs. My ABYC and Cummins INSITE certs let me diagnose a client’s QSC8.3 in 20 minutes last July.

- Tools: They need brand-specific diagnostic laptops and precision gear (e.g., 0.001” micrometers). I caught a $3,000 alignment issue with a feeler gauge in 2024.

- Transparency: A good specialist explains issues clearly, gives detailed estimates, and shows test results. I send clients photos of bad parts—did this for a Sea Ray owner last spring.

- References: Ask for boater feedback at marinas like Dinner Key. A client there recommended me after I fixed his Volvo Penta for $600.

Table: Choosing a Marine Diesel Specialist

I put this together from my South Florida jobs:

| Criteria | What to Look For | Why It Matters | My Experience |

|---|---|---|---|

| Certifications | Yanmar, Cummins, Volvo Penta, ABYC | Ensures brand-specific expertise | ABYC since 2009, Cummins INSITE |

| Tools | Diagnostic laptops, precision gauges | Catches issues fast | Saved $3,000 with a feeler gauge |

| Transparency | Clear explanations, detailed estimates | Builds trust, avoids surprises | Sent photos to a client in 2024 |

| References | Boater feedback at marinas | Proves reliability | Recommended at Dinner Key |

FAQ: Common Marine Diesel Questions

What’s the Most Common Cause of Diesel Engine Failure?

Fuel contamination—water or diesel bug—kills 60% of engines I see. I caught water in a client’s tank at Key Biscayne last July using a phase separation kit. Drain your separator weekly. Contact a marine diesel specialist if filters keep clogging.

How Often Should I Replace My Impeller?

Every year, no exceptions. A $25 impeller prevents $3,000 overhauls. I swapped one on a Sea Ray 350 in 2024—took 30 minutes. Book a marine diesel specialist for this annually.

Why Does My Engine Overheat?

Weak raw water flow, usually a bad impeller or clogged strainer. I fixed a client’s Yanmar 6LY at Stiltsville in 2023—seaweed in the strainer. Check flow at startup; call a marine diesel specialist if it’s weak.

What Does Black Smoke Mean?

Clogged air filter or overloading. I swapped a filter on a Volvo Penta D6 for $30 last month—problem gone. A marine diesel specialist can test air intake with a manometer if it persists.

How Do I Know If I Need a Repower?

If your engine’s unreliable or parts are obsolete, repower. I upgraded a client’s Boston Whaler with a Cummins QSB5.9 in 2023—saved $2,000 yearly on fuel. A marine diesel specialist can assess your engine’s life.

What Tools Should a Marine Diesel Specialist Have?

Brand-specific diagnostic software (e.g., Cummins INSITE), micrometers, and pressure testers. I used INSITE to catch a Volvo Penta fault code in 2024. Ask your specialist to show their setup.

How Much Does a Marine Diesel Specialist Cost?

$120–$160/hour for diagnostics, $200–$15,000 for repairs. I charged $600 for a fuel system fix at Coconut Grove last year. Get a detailed estimate from your marine diesel specialist upfront.

Conclusion: Your Path to Diesel Reliability

Your marine diesel isn’t just an engine—it’s your ticket to worry-free boating. My 15 years as a marine diesel specialist taught me that reliability comes from two things: your 5-minute checks and a pro’s annual service. Start with a daily walkthrough—oil, coolant, fuel, water flow. Then, book a marine diesel specialist for impeller swaps and diagnostics. Vet them for certifications (Yanmar, Cummins) and tools (diagnostic laptops). This partnership saved a client’s Sea Ray from a $5,000 failure last summer. Try my checklist this week, and schedule your service now—your engine’s ready to reward you with smooth voyages.

Author Bio

I’m Alex, a marine diesel specialist with 15 years of experience in South Florida, ABYC-certified since 2009. I’ve serviced 200+ engines, from Yanmars to Volvos, across Miami and Fort Lauderdale. My work’s been praised at Dinner Key and Bahia Mar for saving boats from costly breakdowns.

Leave a Reply