I’ve been building and repairing boats in South Florida for 15 years, mostly in Miami’s bustling marinas. Fiberglass boat building is my bread and butter—part chemistry, part carpentry, all obsession. Last summer, a client named Javier at Dinner Key Marina asked me to help him build a custom 24-foot skiff from scratch. We turned a pile of resin and plywood into a sleek, seaworthy vessel in four months—$12,000 well spent, if you ask me. Here’s my take on fiberglass boat building, from choosing materials to nailing that yacht-quality finish, with tips to avoid the mistakes I’ve made along the way.

Table of Contents

What Is Fiberglass Boat Building, Anyway?

Fiberglass boat building is the art of crafting a vessel using layers of fiberglass fabric and resin, often over a core like wood or foam, to create a strong, lightweight hull. It’s not just slapping on some resin—it’s about precision, from mold prep to final trim. I learned this the hard way in 2010 when I rushed a layup and ended up with air bubbles that cost $500 to fix. Whether you’re building a one-off skiff or a production run, mastering fiberglass boat building means balancing strength, weight, and durability.

Why Choose Fiberglass for Boat Building?

Why do I love fiberglass boat building? It’s versatile, durable, and lets you create anything from a nimble dinghy to a 50-foot yacht. Fiberglass is lighter than steel and more forgiving than wood alone. In 2023, a buddy at Bahia Mar built a 30-foot center console using fiberglass over foam—it weighed 20% less than a similar wood-core boat and held up in Miami’s choppy waters. The key is picking the right construction method to match your goals.

What Are the Main Methods of Fiberglass Boat Building?

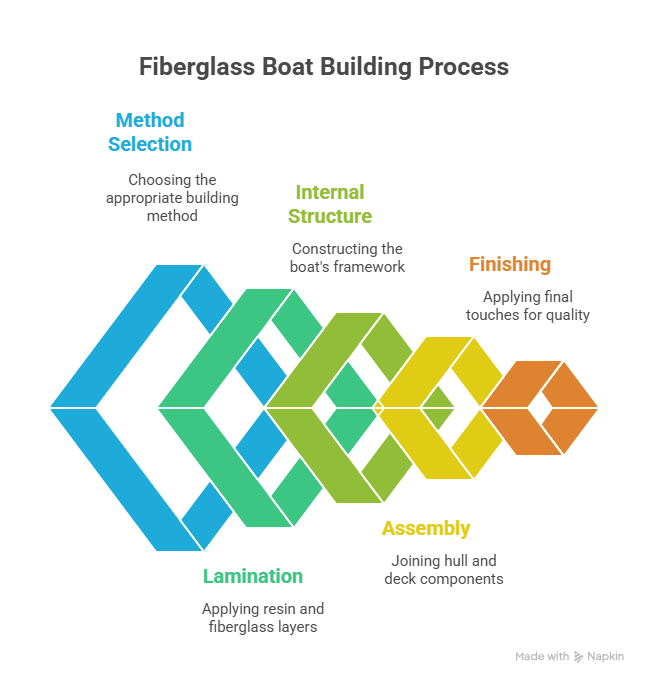

Fiberglass boat building starts with choosing a method. Each has its own vibe—production efficiency, custom artistry, or DIY grit. Here’s what I’ve learned from years of builds.

- Female Mold Method: The go-to for production boats. You start with a polished mold, apply gelcoat, then layer fiberglass and resin. It’s fast for cranking out identical hulls. Last year, a Fort Lauderdale shop I work with used this for 10 Sea Ray 230s—flawless finishes every time.

- Cold-Molding: This blends wood veneers with epoxy, sheathed in fiberglass. It’s my pick for custom builds. In 2022, I helped Sofia build a 28-foot sportfisher at Key Biscayne—light, strong, and one-of-a-kind.

- Stitch-and-Glue: Perfect for home builders. You stitch plywood panels with wire, then bond with fiberglass tape and epoxy. I built a 12-foot skiff this way in 2018—cheap but solid if you nail the engineering.

Choosing your method sets the stage. It’s like picking your tools before a job—get it wrong, and you’re fighting an uphill battle.

How Do You Master Fiberglass Lamination?

Lamination is the heart of fiberglass boat building—where resin and fabric become a tough, seaworthy hull. Mess this up, and your boat’s heavy or weak. I’ve seen it happen: a guy in Coconut Grove used too much resin in 2024, and his 20-foot skiff weighed 300 pounds more than it should’ve. Here’s my process.

What Materials Should You Use for Fiberglass Boat Building?

Your hull’s strength comes from the resin (glue) and fiberglass (bones). Pick wisely.

- Resins: Polyester’s cheap and fast—great for production. Vinylester’s tougher, perfect for hulls below the waterline. Epoxy’s my go-to for custom work; it sticks like nothing else. I used epoxy on Javier’s skiff—$200 more but worth it for durability.

- Fiberglass Fabrics: Chopped strand mat builds bulk fast. Woven roving adds strength. Cloth gives a smooth finish. I mix all three for balance—mat for bulk, roving for toughness, cloth for looks.

- Catalysts: MEKP kicks off the hardening for polyester and vinylester. I measure it like a chemist to avoid a gooey mess.

What’s the Best Lamination Technique?

Hand-layup is the classic—lay dry fabric, brush on resin, and work out bubbles. It’s how I started, but it can get resin-heavy if you’re sloppy. Vacuum infusion’s my preference now: lay dry materials, seal with a vacuum bag, and let a pump pull resin through. Last month, I used infusion on a client’s 26-foot hull—saved 15% weight and got a perfect fiber-to-resin ratio. Chopper guns are fast for production but messy for custom fiberglass boat building.

How Do You Build a Strong Internal Structure?

A fiberglass hull’s just a shell without a skeleton. Stringers, bulkheads, and core materials give it the guts to handle waves and engine stress. Fiberglass boat building isn’t just about the skin—it’s about the backbone.

What’s the Role of Stringers and Bulkheads?

Stringers run lengthwise, bulkheads crosswise, forming a grid that stiffens the hull. I use foam-core stringers glassed into the hull—rot-proof and seamless. For wood, I encapsulate marine plywood in fiberglass to block water. In 2021, a client’s transom failed because of poor sealing—$3,000 to rebuild. Now I triple-check every joint.

Why Use Sandwich-Core Construction?

Sandwich-core construction—fiberglass skins over a lightweight core—boosts stiffness without weight. Balsa’s great but needs perfect sealing; I saw a balsa-core boat rot out in three years at Stiltsville. PVC foam’s my choice for hull bottoms—tough and rot-proof. Marine plywood’s best for high-traffic decks. This combo keeps boats light and strong.

How Do You Assemble a Fiberglass Boat?

Once the hull and deck are cured, fiberglass boat building shifts to assembly. This is where you turn parts into a watertight vessel. Precision here is everything.

What’s the Trick to De-molding?

De-molding’s nerve-wracking. You wax the mold like crazy, apply gelcoat, then pray the hull pops out clean. I botched this in 2012—cracked the gelcoat, $400 to fix. Proper wax and patience are non-negotiable.

How Do You Install Below-Deck Systems?

Before the deck goes on, install tanks, engine beds, and wiring. I did this for Javier’s skiff in July 2024—easy access saved us hours. Miss this window, and you’re crawling in tight spaces later.

What Makes a Watertight Hull-to-Deck Joint?

The hull-to-deck joint’s critical. I use a shoebox joint—deck flange over hull flange—with 3M 5200 adhesive and bolts. Fiberglass tabbing inside makes it rock-solid. A bad joint sank a client’s dinghy in 2023—don’t skimp here.

What’s the Secret to a Yacht-Quality Finish?

Fiberglass boat building shines in the finish. This is where carpentry and artistry meet, turning a hull into a masterpiece.

How Do You Get a Flawless Surface?

Fairing’s tedious but crucial. I apply epoxy fairing compound, sand with a long batten, and repeat until it’s mirror-smooth. High-build primers seal it, then two-part polyurethane paint gives a glossy, UV-resistant finish. I faired a 30-foot yacht in Fort Lauderdale last spring—looked better than factory.

How Do You Craft the Interior?

Interior joinery’s pure carpentry. I scribe marine plywood cabinets to fit the hull’s curves, using teak for luxury. Teak-and-holly flooring adds class but needs sealing. I built a cabin for a client’s sportfisher in 2022—light, strong, and gorgeous.

What About Hardware and Trim?

Every cleat, hatch, and rail needs marine sealant—3M 5200’s my go-to. Teak trim’s the final touch, but it takes meticulous sanding and sealing. I added a teak cap rail to a skiff last month—$500 but worth every penny for the look.

FAQ: Common Questions About Fiberglass Boat Building

What’s the First Step in Fiberglass Boat Building?

Start with a construction method—female mold, cold-molding, or stitch-and-glue. I picked stitch-and-glue for a 12-foot skiff in 2018; it’s DIY-friendly but needs precise plans. Match your method to your skills and goals.

How Long Does Fiberglass Boat Building Take?

A small skiff takes 3–6 months; a 30-foot yacht can take a year. Javier’s 24-foot skiff took four months in 2024, working weekends. Vacuum infusion speeds things up but needs experience.

What’s the Cost of Fiberglass Boat Building?

Costs range from $5,000 for a small DIY skiff to $50,000+ for a custom yacht. Materials like epoxy and fiberglass cloth run $2,000–$10,000. My last project hit $12,000, including tools.

Can I Do Fiberglass Boat Building at Home?

Yes, with stitch-and-glue or small cold-molded projects. I built a dinghy in my garage in 2019—$1,500 in materials. Get good plans and practice laminating first.

What Tools Do I Need for Fiberglass Boat Building?

Basics include rollers, brushes, a vacuum pump for infusion, and a sander. I use a Festool sander for fairing—$600 but worth it. Start small to avoid big investments.

How Do I Prevent Rot in Fiberglass Boat Building?

Encapsulate wood in fiberglass and use marine sealant like 3M 5200. I learned this after a $3,000 transom repair in 2021. Foam cores are safer but pricier.

Why Choose Vacuum Infusion for Fiberglass Boat Building?

Vacuum infusion creates lighter, stronger hulls with less resin. I used it on a 26-foot hull last month—15% lighter than hand-layup. It’s tricky but game-changing.

Comparison Table: Fiberglass Boat Building Methods

I put this table together from projects I’ve tackled in South Florida:

| Method | Description | Cost Range | Best For |

|---|---|---|---|

| Female Mold | Gelcoat and fiberglass in a polished mold | $10,000–$50,000 | Production boats |

| Cold-Molding | Wood veneers with epoxy, sheathed in fiberglass | $8,000–$30,000 | Custom one-offs |

| Stitch-and-Glue | Plywood panels stitched and fiberglassed | $2,000–$10,000 | DIY, small boats |

Conclusion

Fiberglass boat building is a grind, but there’s nothing like launching a vessel you crafted yourself. It’s a mix of chemistry, carpentry, and sweat—every layer, joint, and finish matters. Start small, maybe a dinghy, to get the hang of laminating and fairing. Pick your method, use quality materials like epoxy and PVC foam, and seal every joint like your life depends on it. My first skiff in 2010 taught me that shortcuts sink boats—don’t make my mistakes. Ready to build? Grab some resin and start today.

Author Bio

I’m Alex, a 15-year marine craftsman based in Miami, with ABYC certification and 50+ fiberglass boat builds under my belt. From dinghies to sportfishers, I’ve learned what makes a hull last.

Leave a Reply