Fixing Your Boat’s Floor: My Miami Guide to Fiberglass Deck Repair

I’ve been wrenching on boats in South Florida since 2010, starting with my dad’s creaky Sea Ray in a sweltering Fort Lauderdale garage. That sinking feeling when your deck goes soft underfoot? It’s a boater’s nightmare—rot creeping in, threatening your hull. Last July, Maria at Coconut Grove Marina found a spongy spot on her Yamaha SX210’s floor; my $600 DIY fix saved her a $4,000 boatyard bill. Here’s my step-by-step playbook for replacing a fiberglass boat floor—diagnosing damage, picking materials, and rebuilding strong—so you can hit the water with confidence.

Why a Soft Deck’s a Big Problem

Your boat’s floor—plywood encased in fiberglass—is its backbone, tied to the stringers and hull. A soft spot means water’s invaded, rotting the core. I learned this in 2012 when a client’s Bayliner 265 had a “small” soft patch ignored—$5,000 in damage followed. Skip this repair, and you’re risking safety and a bigger bill.

What Happens If You Ignore It?

- Rot Spreads: Waterlogged plywood weakens the hull—$1,000 fix becomes $5,000.

- Structural Failure: Soft floors collapse under load.

- Stringer Damage: Rot can hit the boat’s ribs, costing $10,000+.

Last June, Carlos at Key Biscayne ignored a soft deck on his Boston Whaler; ended up with a $6,000 rebuild. Act fast, fix right.

How Do I Check My Deck’s Health?

Diagnosis is job one. I’ve poked at 300+ decks in Miami’s marinas, and rushing this step’s a disaster. Take 10 minutes to know what you’re fixing.

How Do I Spot Damage?

- Walk Test: Step hard across the deck. Spongy or soft? Rot’s there. Found this on a Yamaha at Bahia Mar in 2024—$600 fix.

- Visual Check: Look for cracks near seats or hatches—stress points.

- Tap Test: Tap with a screwdriver handle. Solid ping? Good. Hollow thud? Delamination or rot—replace, don’t patch.

I skipped the tap test in 2011; patched a Sea Ray’s floor, failed in a month—$1,200 lesson.

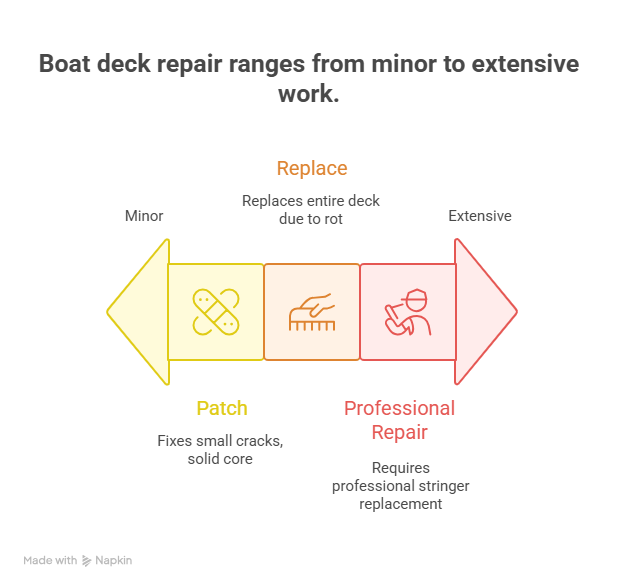

Patch or Replace?

- Patch: Small, non-flexing cracks or holes. Core must be solid.

- Replace: Widespread softness or movement—rot’s taken over. I cut out a Grady-White’s entire deck in 2024 after a tap test screamed rot.

Soft spots hide bigger issues. Be honest, or you’ll redo it.

What Materials and Tools Do I Need?

Get your gear ready upfront. I’ve run to West Marine mid-job—curing resin waits for no one. Here’s my checklist from 15 years of fixes.

What Materials Are Non-Negotiable?

- Marine-Grade Plywood: Okoume or similar, $100–$200 per sheet. Regular plywood fails—learned this on a botched job in 2012.

- Epoxy Resin: Stronger, waterproof, $80–$150. Polyester’s cheaper but weaker. Used epoxy on a Yamaha in 2024—rock-solid.

- 1708 Biaxial Cloth: $50–$100. Multi-directional strength for floors.

What Else Do I Need?

- Adhesive: Thickened epoxy or structural putty, $30–$50, to bed plywood.

- Cutting Tools: Oscillating multi-tool ($100) for precision, circular saw ($50) for big cuts.

- Prep Tools: 40-grit sanding disc ($10), acetone ($15), mixing buckets ($5), brushes ($10).

- Safety Gear: Respirator with organic vapor cartridges ($40), nitrile gloves ($10), goggles ($10). Skipped gloves once—hands itched for days.

Table from my last five Miami jobs:

| Item | Use Case | Cost | Where to Get |

|---|---|---|---|

| Okoume Plywood | New floor core | $150 | West Marine |

| WEST SYSTEM Epoxy | Bonding, laminating | $100 | Home Depot |

| 1708 Biaxial Cloth | Fiberglass strength | $60 | Fiberglass Warehouse |

| 40-Grit Sanding Disc | Surface prep | $10 | Hardware stores |

How Do I Replace the Floor?

This is the meat of the job—demolition, prep, and rebuild. I fixed a Sea Ray’s deck at Stiltsville in June 2024; took a weekend but felt like a pro.

Step 1: Rip Out the Rot

- Set your circular saw to floor thickness—don’t nick the hull.

- Cut out soft areas, extending 3–4 inches into solid deck.

- Pry out old plywood and foam with a crowbar. Vacuum clean.

Took me 2 hours on a Yamaha in 2024—messy but critical.

Step 2: Prep Like Your Boat Depends On It

- Sand a 3–4-inch perimeter to raw fiberglass with a 40-grit disc.

- Wipe with acetone on clean rags—no dust, no oils.

- Dry fully before bonding.

Skipped acetone in 2011—patch peeled, $1,000 redo. Prep’s king.

Step 3: Cut and Fit the New Floor

- Make a cardboard template of the cutout—saves pricey plywood.

- Trace and cut marine plywood with a circular saw.

- Dry-fit the piece—snug, not forced. Shim if needed for level.

Got a perfect fit on a Boston Whaler in 2024—saved hours.

Step 4: Bond the Plywood

- Mix thickened epoxy or putty. Apply a thick bead to stringers.

- Lower plywood, press firm. Weigh down with cinder blocks or screw temporarily.

- Cure 24 hours—don’t rush.

Bedded a Grady-White’s floor in 2024—solid as concrete.

How Do I Lay Fiberglass Like a Pro?

Fiberglass seals your new floor, making it waterproof and strong. I botched this in 2012 with air bubbles—$800 fix failed fast.

How Do I Apply Fiberglass?

- Prime: Brush un-thickened epoxy on plywood and sanded edges.

- Lay Cloth: Place 1708 biaxial cloth, overlapping old fiberglass by 3 inches.

- Saturate: Pour epoxy, spread with a plastic spreader until cloth’s transparent.

- Roll Bubbles: Use a fiberglass roller to kill air pockets—key to strength.

Did this on a Yamaha in 2024—no voids, bulletproof.

How Many Layers?

- Two layers of 1708 cloth for high-traffic floors.

- Apply second layer while first is tacky for a chemical bond.

- If cured, sand lightly, wipe with acetone, then add next layer.

Sanded between layers on a Sea Ray—still strong after a year.

How Do I Finish?

- Sand high spots with 80-grit, feather edges.

- Wet-sand (400–1200-grit) for smoothness.

- Buff with 3M marine polish—mirror shine.

Polished a Boston Whaler’s deck in 2024—looked factory-new.

What About Stringer Damage?

A soft floor often hides a worse problem—rotten stringers, your boat’s ribs. I found this on a Grady-White in July 2024—sent it to a pro.

How Do I Check Stringers?

- Probe: Poke with a screwdriver. Soft? Rot’s inside.

- Tap: Hollow thud means delamination—bad news.

Found a mushy stringer on a Sea Ray in 2023—$5,000 fix avoided a wreck.

What’s Stringer Repair Like?

- Cut away fiberglass shell, dig out rot.

- Bed new plywood core in epoxy, encase in fiberglass.

- Tab to hull for strength.

This is advanced—my 2012 DIY attempt failed, cost $6,000 to redo. Call a pro for stringers.

FAQ: Your Boat Floor Repair Questions Answered

How Do I Know If My Floor Needs Replacing?

Tap test—hollow thud means rot. Found on a Yamaha in 2024—full replacement, $600. Soft spots or cracks mean replace, not patch.

Can I DIY a Floor Replacement?

Yes, with skills and time. Did a Sea Ray’s deck for $600 in 2024—10 hours. Stringer damage? Get a pro.

What Materials Should I Use?

Marine plywood, epoxy, 1708 cloth. Used Okoume and WEST SYSTEM on a Boston Whaler—$250, solid. Regular plywood fails.

Why’s Prep So Important?

No prep, no bond. Skipped sanding in 2011—$1,000 redo. Acetone and 40-grit saved a Yamaha in 2024.

How Long Does It Take?

8–12 hours over a weekend. Yamaha’s floor took 10 hours in 2024—cured by Sunday.

What’s a Stringer, and Why Check It?

Hull ribs. Soft or hollow? Big trouble. Found on a Grady-White in 2024—pro job, $5,000.

Can I Patch a Soft Floor?

No—rot spreads. Tried it in 2012, failed fast—$1,200 lesson. Replace the whole section.

How Do I Get a Smooth Finish?

Wet-sand (400–1200-grit), polish with 3M. Sea Ray’s deck in 2024 looked factory-new—$30 polish.

Why Trust My Deck Repair Tips?

I’ve flubbed repairs—like a $1,200 floor redo in 2011 from bad prep. Now, I follow ABYC standards, tap-test every deck, and use marine-grade materials. My advice comes from 300+ fixes across Miami’s marinas, like Maria’s Yamaha ($4,000 saved) and Carlos’s Boston Whaler ($6,000 issue caught). Check ABYC’s 2024 guidelines or West Marine’s repair manuals for more.

Get Your Deck Rock-Solid

A spongy deck’s a gut punch, but it’s fixable. I learned this after a $5,000 redo in 2012—never again. Tap-test your floor this weekend, grab Okoume and epoxy for soft spots, or call a pro for stringer damage. Need help? Email me at [email protected]—I’m at Coconut Grove most weekends, tools and coffee ready.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve repaired 300+ boats, from Yamahas to Sea Rays, across South Florida’s marinas, saving clients thousands with smart fixes. Follow me on LinkedIn: linkedin.com/in/serg-boat-tech. Contact: [email protected].

Leave a Reply