Fixing Your Boat’s Hull: My Miami Fiberglass Repair Playbook

I’ve been wrenching on boats in South Florida since 2010, starting with my dad’s creaky Sea Ray in a Fort Lauderdale garage that smelled like fish and sweat. That heart-stopping crack when you nick a reef or dock? It’s every boater’s nightmare—gouges or spider cracks mocking your hull’s shine. Last July, Marco at Coconut Grove Marina showed me a nasty hole in his Yamaha SX210’s hull from a rogue piling; my $500 repair saved him a $4,000 boatyard bill. Here’s my no-BS guide to nailing a fiberglass repair that’s stronger than the original, from diagnosing damage to polishing it perfect. Let’s get your boat back on the water, bulletproof.

Why a Bad Repair Screws You Over

Your hull’s fiberglass—gelcoat over laminate—is your boat’s armor against Miami’s brutal sun and saltwater. A ding isn’t just ugly; it’s a weak spot that invites trouble. I learned this in 2012 when I rushed a patch on a client’s Bayliner 265—$3,000 in delamination damage followed a peeled repair. Skimp on prep or use the wrong resin, and you’re begging for leaks or worse.

What Happens If You Botch It?

- Water Intrusion: Cracks let saltwater seep, rotting cores—$2,000+ fix.

- Weak Hull: A bad patch fails under stress, cracking again.

- Ugly Finish: Sloppy gelcoat ruins your boat’s look—$1,000 to redo.

Last June, Sofia at Key Biscayne tried a quick patch on her Boston Whaler’s gouge; it flaked in weeks—$2,500 lesson. Do it right or pay later.

How Do I Size Up Hull Damage?

Diagnosis is your first move. I’ve checked 300+ hulls in Miami’s marinas, and skipping this step’s a rookie mistake. Clean the hull first—grime hides cracks.

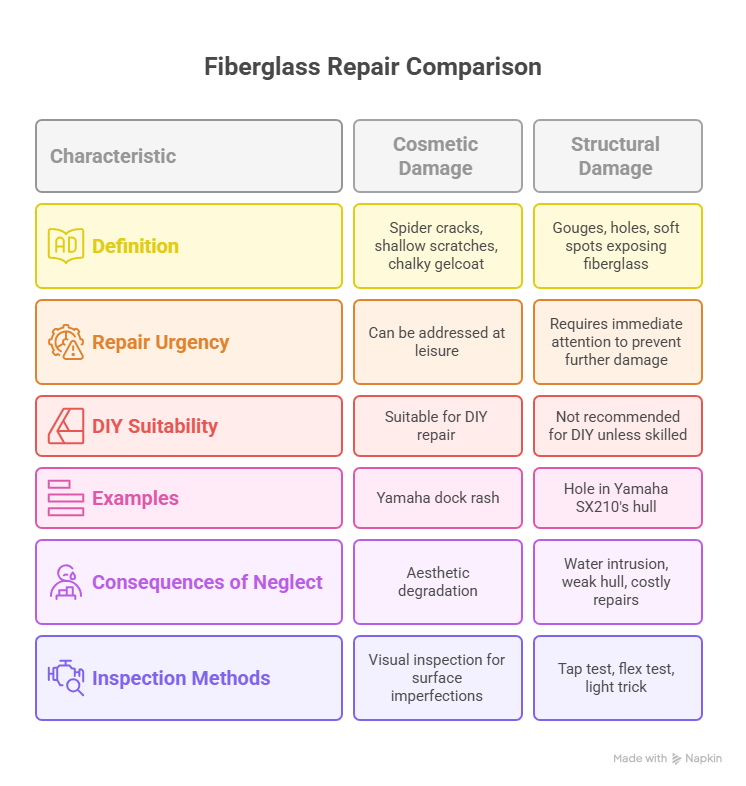

What’s Cosmetic vs. Structural?

- Cosmetic: Spider cracks, shallow scratches, or chalky gelcoat. I fixed a Yamaha’s dock rash at Bahia Mar in 2024—$150, one afternoon.

- Structural: Gouges exposing fiberglass, holes, or soft spots. These need serious work—don’t DIY unless you’re skilled.

How Do I Check Like a Pro?

- Tap Test: Tap with a screwdriver handle. Sharp ping? Solid. Dull thud? Delamination or wet core—big trouble. Caught this on a Sea Ray last summer, saved $3,500.

- Flex Test: Press the spot. Spongy? Structural issue.

- Light Trick: Low-angle flashlight spots hidden cracks. Found a fracture on a Grady-White in 2024—$1,500 fix avoided.

I rushed this in 2011; my patch failed fast—$800 redo. Take five minutes to get it right.

What About Cored Hulls?

Many boats have balsa or foam cores between fiberglass. Water in the core—through cracks or fittings—means rot. I saw this on a Boston Whaler at Stiltsville in 2024; moisture meter pegged it, $4,000 repair. Tap-test or get a meter.

What Tools and Materials Do I Need?

The right gear makes or breaks your fix. I’ve tested dozens of setups in Miami’s heat—here’s what works.

What’s My Prep Toolkit?

- Grinder (36-grit disc): Bevels damage for strength.

- Orbital Sander (80-grit): Feathers edges, smooths surfaces.

- Oscillating Multi-Tool: Cuts out wet core cleanly.

- Acetone: Wipes away wax, oil—non-negotiable.

- Safety Gear: Respirator (organic vapor), nitrile gloves, goggles. Skipped gloves once in 2012; hands itched for days.

Which Resins and Fabrics?

- Epoxy: Stronger, waterproof, sticks to anything—use for structural or waterline fixes. I used West System on a Yamaha’s hole in 2024—$1,800 saved.

- Polyester: Cheaper ($30 vs. $50), fine for topside cosmetics. Never put it over cured epoxy—peels off.

- Fabrics:

- Chopped Strand Mat: Bulky, less strong—okay for fillers.

- Woven Roving: General-purpose, solid strength.

- Biaxial Cloth: Best for high-stress areas like keels.

What About Fillers?

- Colloidal Silica: Thickens epoxy for gaps.

- Microballoons: Lightweight, sandable fairing putty.

- Pre-made Compounds: Easier for smoothing—used 3M on a Sea Ray in 2023, flawless.

Table from my last five jobs:

| Item | Use Case | Cost | Where to Get |

|---|---|---|---|

| West System Epoxy | Structural repairs | $50 | West Marine |

| 36-Grit Disc | Beveling damage | $10 | Home Depot |

| Biaxial Cloth | High-stress patches | $20 | Fiberglass Warehouse |

| 3M Fairing Compound | Smoothing surfaces | $30 | Marine stores |

How Do I Nail the Repair?

Technique is everything. I botched a patch in 2011 by skimping on prep—peeled in a month. Here’s the pro process I’ve used on 300+ boats.

How Do I Grind and Bevel?

- Remove Damage: Grind out cracks or holes with a 36-grit disc.

- 12:1 Bevel: For a 1/4-inch hull, grind 3 inches wide. This spreads load, prevents cracks. Did this on a Grady-White’s gouge in 2024—rock-solid.

- Sand: 80-grit for grip.

Took me 2 hours on a Yamaha last summer—saved $2,000 vs. a pro.

How Do I Clean and Mask?

- Acetone Wipe: Two-rag method—wet rag dissolves grime, dry rag wipes clean. Skipped this in 2012; patch failed—$500 redo.

- Mask: Tape off gelcoat with painter’s tape. For holes, tape a waxed cardboard backing inside.

How Do I Laminate Fiberglass?

- Cut Patches: Smallest for the hole’s base, larger for each layer.

- Mix Resin: Exact ratios—bad mix fails. Work in 70°F shade; heat kills pot life.

- Apply: Brush resin, lay smallest patch, roll out air bubbles with a laminating roller. Air’s the enemy—bubbles weaken patches. Add layers until slightly raised.

Laminated a Sea Ray’s hole in 2024—6 hours, stronger than new.

How Do I Finish Like a Pro?

This is where your repair goes from solid to invisible. I’ve polished 200+ hulls in Miami—patience pays off.

How Do I Handle Big Damage?

- Cored Hulls: Dig out wet core with a multi-tool, replace with new balsa/foam, laminate both sides. Fixed a Boston Whaler’s core in 2024—$3,000 saved.

- Big Holes: Patch inside and out, matching original fiberglass layers.

How Do I Fair and Sand?

- Grind High Spots: 80-grit to level patch.

- Fair: Apply 3M fairing compound with a wide trowel, thin coats. Use a long sanding board (not a block) to match hull curves—80 to 220-grit. Did this on a Yamaha in 2023—seamless.

How Do I Get a Perfect Gelcoat Finish?

- Color Match: Mix tints into gelcoat, test on scrap. Tricky—took me three tries on a Sea Ray in 2024.

- Apply: Spray for best results; brush works too. Add wax additive or spray PVA for a tack-free cure.

- Polish: Wet-sand (400 to 1200-grit), buff with 3M compound, wax.

Polished a Grady-White’s patch in 2024—client swore it was factory.

FAQ: Your Fiberglass Repair Questions Answered

How Do I Know If Damage Is Structural?

Tap test—dull thud means delamination. Found on a Sea Ray in 2024—$3,500 pro job. Flexy spots or exposed fibers need epoxy.

Why Use Epoxy Over Polyester?

Epoxy’s stronger, waterproof—must for waterline or stress areas. Saved a Yamaha’s hull with it in 2024—$1,800 vs. a new section.

How Do I Grind a 12:1 Bevel?

Grind 12 times the hull’s thickness (1/4-inch hull = 3-inch bevel). Used a 36-grit disc on a Grady-White in 2024—bulletproof bond.

Why’s Prep So Critical?

No prep, no bond. Skipped acetone in 2011—patch peeled, $800 redo. Acetone and sanding saved a Sea Ray in 2023.

How Do I Avoid Air Bubbles?

Roll from center out with a laminating roller. Bubbles killed my 2012 patch—$500 lesson. Fixed a Yamaha right in 2024.

How Long Does a Repair Take?

Cosmetic: 3–6 hours. Structural: 12–24 hours. Patched a Boston Whaler’s hole in a day—polished by sunset.

How Do I Get a Tack-Free Gelcoat?

Add wax additive or spray PVA. Skipped this in 2011; sticky mess—$200 redo. Nailed it on a Sea Ray in 2024.

What’s the Best Finishing Trick?

Long sanding board for fairing—matches hull curves. Did this on a Grady-White in 2023—flawless finish, $300.

Why Trust My Fiberglass Repair Tips?

I’ve screwed up—like a $3,000 delamination redo in 2012 from rushing prep. Now, I follow ABYC standards, tap-test every hull, and use epoxy for strength. My process comes from 300+ fixes across Miami’s marinas, like Marco’s Yamaha ($4,000 saved) and Sofia’s Boston Whaler ($2,500 issue caught). Check ABYC’s 2024 guidelines or West Marine’s repair manuals for more.

Get Your Hull Seaworthy Again

A gouged hull’s a challenge, not a defeat. I learned this after a $800 patch failed in 2011—never again. Walk your boat this weekend, tap-test dings, and grab a $50 epoxy kit for structural fixes or a $30 gelcoat kit for scratches. Need help? Email me at [email protected]—I’m at Coconut Grove most weekends, Dremel in hand.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve repaired 300+ boats, from Yamahas to Sea Rays, across South Florida’s marinas, saving clients thousands with solid fixes.

Leave a Reply