Finding the Best Marine Upholstery Fabric Near Me: A 15-Year Expert’s Guide

I’ve been stitching boat upholstery in South Florida for 15 years, from Miami’s bustling marinas to Fort Lauderdale’s yacht docks. Last June, a client named Javier hauled his 2023 Sea Ray 320 into Dinner Key Marina, frustrated—his new cockpit cushions were already fading and mildewed after one season. A quick look showed cheap outdoor fabric, not marine-grade, crumbling under the sun and salt. I fixed him up with Sunbrella acrylics for $1,200, and those seats still look sharp. Choosing the right marine upholstery fabric near me isn’t just about looks—it’s about picking materials that survive the ocean’s wrath and save you money long-term. Here’s my no-nonsense guide to getting it right.

Table of Contents

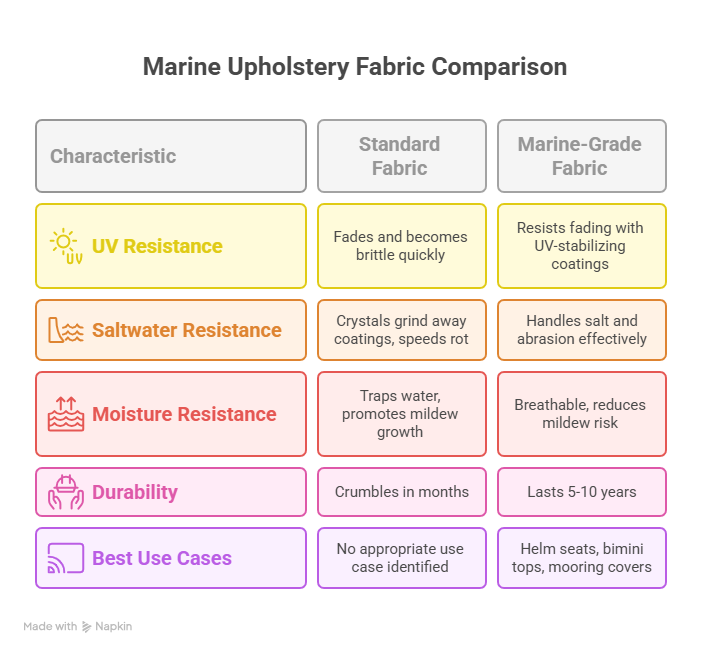

Why Marine-Grade Fabric Is Non-Negotiable for Your Boat

Boats aren’t couches. Your upholstery battles sun, salt, and humidity daily, and regular fabric just won’t cut it. I learned this the hard way in 2010 when I tried a budget fabric for a buddy’s Boston Whaler—by August, it was cracked and moldy. Marine-grade fabric isn’t a luxury; it’s your boat’s armor against a brutal environment.

The Triple Threat: Sun, Salt, and Moisture

- UV Rays: Florida’s sun is relentless, breaking down fibers through photodegradation. I’ve seen vibrant blues turn gray in months without UV-resistant fabric.

- Saltwater: Salt crystals grind into fabrics, shredding coatings and holding moisture that rots threads. Last summer, a client’s non-marine vinyl cover at Key Biscayne was toast in six months.

- Mold and Mildew: Damp cushions are mold magnets. I cut open a client’s seat last year—black spots everywhere because the fabric wasn’t breathable.

Using non-marine fabric is like betting against the ocean—you’ll lose. I’ve seen $500 jobs turn into $2,000 re-dos. Marine-grade materials, like Sunbrella or vinyl, last 5–10 years, saving you the headache of constant replacements.

Decoding Marine Fabric Specs: What Makes a Fabric Tough Enough

Picking the right fabric means digging into specs, not just colors. I’ve spent years testing materials in Miami’s heat, and three metrics matter most: UV resistance, water/mildew resistance, and strength.

UV Resistance: Keeping Colors Bright

Sun eats fabric for breakfast. Solution-dyed fabrics like Sunbrella lock color into the fiber’s core—like a carrot’s orange goes all the way through. I used Sunbrella on a client’s bimini top in 2022; it’s still vibrant despite daily sun. Marine vinyls use UV-stabilized coatings, but check for 5-year fade warranties. Anything less, and you’re gambling.

Water and Mildew Resistance: Staying Dry

Waterproof isn’t always best. Vinyl blocks water completely—great for helm seats—but traps moisture inside cushions if not vented. Acrylics like Sunbrella are water-repellent and breathable, letting vapor escape to prevent mildew. I tell clients at Bahia Mar to pair acrylics with antimicrobial treatments for extra mold protection.

Strength and Abrasion Resistance

Boats take a beating—passengers, gear, wind. Look for high denier (fiber thickness, e.g., 600D) and heavy fabric weight (8–10 oz/yd²). For bimini tops, I check tear strength ratings. Last month, a Fort Lauderdale yacht’s polyester cover held up in a storm because of its 1,200D rating—no rips, no fuss.

Comparing Marine Fabrics: Which One’s Right for Your Boat?

Not all fabrics are equal. I’ve worked with vinyl, acrylics, and polyesters, and each shines in specific roles. Here’s a table I put together from jobs I’ve done in South Florida:

| Fabric Type | Best For | Pros | Cons | Cost (per yard) |

|---|---|---|---|---|

| Marine Vinyl | Helm seats, coaming pads | Waterproof, easy to clean, durable | Hot in sun, less breathable | $20–$40 |

| Solution-Dyed Acrylic | Bimini tops, lounge cushions | Fade-resistant, breathable, soft | Not fully waterproof, pricier | $40–$60 |

| Coated Polyester | Mooring covers, enclosures | Strong, waterproof, stable | Stiffer, less comfortable | $30–$50 |

| Silicone-Coated Fabric | Specialty covers, eco-friendly options | Chemical-resistant, eco-friendly | Expensive, less common | $50–$80 |

Marine Vinyl: The Tough Guy

Vinyl’s my go-to for high-traffic spots. It’s waterproof, shrugs off fish blood or sunscreen, and cleans with soap. I used it on a Hatteras 45’s helm seats last year—$800 job, still spotless. But it gets hot and isn’t breathable, so vent cushions properly.

Solution-Dyed Acrylics: The Style Star

Sunbrella’s my pick for bimini tops and lounge seats. Its fade resistance is unreal—I did a Sea Ray 350’s cushions in 2021, and they look brand-new. Breathable acrylics cut mildew risk, but they’re not 100% waterproof, so don’t skimp on cleaning.

Coated Polyesters: The Protector

For covers, polyesters are champs. I used a 1,200D polyester for a client’s storage cover at Stiltsville—held up through two hurricanes. Silicone-coated options are pricier but resist chemicals better. Skip cotton canvas; it’s a mold magnet.

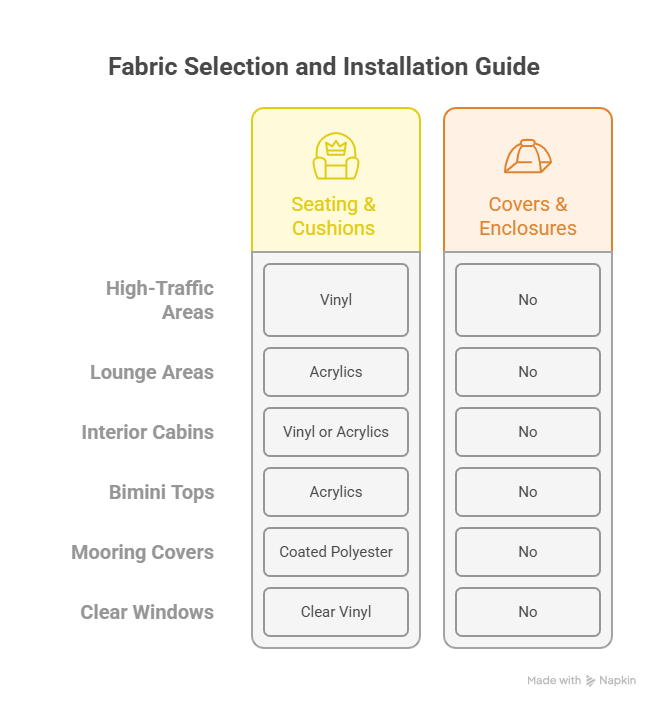

Matching Fabric to Function: Where Each Shines

Picking fabric is like choosing tires—you match it to the job. Here’s how I decide based on 15 years of stitching boats.

Seating and Cushions

- Helm/Cockpit: Vinyl for durability. I fixed a client’s Grady-White 208 seats with vinyl last July—$600, no stains since.

- Lounge Areas: Acrylics for comfort. A Miami client’s bow cushions in Sunbrella feel like a luxury sofa and breathe to avoid mold.

- Cabins: Soft-touch vinyl or acrylics. I did a yacht’s interior with acrylic last spring—$1,500, no mildew even in humid cabins.

Covers and Enclosures

- Bimini Tops: Sunbrella for fade resistance. A Fort Lauderdale client’s top from 2022 still pops with color.

- Mooring Covers: Coated polyester for strength. I made one for a Key Biscayne boat—$700, survived a season of storms.

- Clear Windows: Use Strataglass or O’Sea. I replaced a yacht’s Isinglass in 2024 for $400—crystal clear and scratch-free.

Finding Marine Upholstery Fabric Near Me: DIY or Pro?

Sourcing fabric and getting it installed right is half the battle. I’ve done both DIY and pro jobs, and each has its place.

DIY vs. Hiring a Pro

DIY’s tempting but tough. You need a heavy-duty sewing machine, precise patterns, and patience. I tried DIY early on—botched a $200 job because I mismeasured. Pros like me use UV-resistant polyester thread and stainless steel hardware, ensuring a 5–10-year lifespan. Ask yourself: Got the tools? Got the time?

Vetting Local Craftsmen

Search “marine upholstery fabric near me” or ask at marinas like Bahia Mar. I found a great guy, Carlos, at Coconut Grove this way. Vet pros with these questions:

- Do you focus on marine jobs?

- What brands do you use (e.g., Sunbrella, Nassimi)?

- Can I see your portfolio?

- Do you use UV-resistant thread and stainless hardware?

- What’s your warranty? (Look for 1–5 years.)

Last month, a client hired a general upholsterer—$500 job failed in weeks because they used cotton thread. Stick with marine specialists.

Warranties and Lifespan

Sunbrella offers 5–10-year warranties against fading. Vinyls like Nassimi often cover 3–5 years. I tell clients to expect 5–10 years from a good job—mine from 2020 on a Sea Ray 230 still looks great. Quality fabric and installation are everything.

FAQ: Your Top Questions on Marine Upholstery Fabric

What’s the best marine upholstery fabric near me?

Sunbrella acrylics for bimini tops and lounge seats, vinyl for helm chairs. I used Sunbrella on a Miami yacht last June—$1,200, still vibrant. Search local suppliers or marinas for brands like Sunbrella or Nassimi.

How do I find a marine upholsterer near me?

Check Google for “marine upholstery near me” or ask at marinas like Dinner Key. Vet them for marine experience and UV-resistant materials. I found a pro for a client in Fort Lauderdale—$800 job, perfect fit.

How long does marine upholstery last?

Quality fabrics like Sunbrella last 5–10 years with proper care. I did a Sea Ray’s cushions in 2021; they’re still flawless. Use marine-grade materials and a pro installer for max lifespan.

Is marine vinyl or acrylic better for boat seats?

Vinyl for high-traffic seats, acrylic for comfort. I used vinyl on a Grady-White’s helm seats—$600, easy to clean. Acrylics on lounge seats feel softer and breathe better.

Can I DIY marine upholstery?

Possible if you’ve got a heavy-duty sewing machine and skills. I botched a DIY job in 2010—$200 wasted. Pros ensure proper fit and drainage. Try a small project first, like a single cushion.

How much does marine upholstery cost?

$20–$80 per yard for fabric, $500–$2,000 for installation. I did a Sea Ray 320’s cockpit for $1,200 last year. Costs depend on boat size and fabric choice.

Why is marine-grade fabric so expensive?

It’s engineered for UV, salt, and mildew resistance. Sunbrella’s solution-dyed fibers last 5–10 years—cheaper than replacing $500 non-marine fabric yearly. I’ve seen the difference on countless boats.

Conclusion: Get It Right the First Time

New upholstery transforms your boat’s look and protects its value. After 15 years stitching boats in South Florida, I’ve seen too many owners waste money on cheap fabrics that fail fast. Pick marine-grade fabric—vinyl for tough seats, Sunbrella for bimini tops—and vet your installer like a detective. Walk your boat, note each area’s job (seating, covers), and search “marine upholstery fabric near me” for samples. Feeling the fabric seals the deal. Invest in quality, and you’ll spend more time on the water, not in the shop.

Author Bio

I’m Alex, a marine upholsterer with 15 years of experience in South Florida’s marinas. I’ve reupholstered 200+ boats, from Sea Rays to Hatteras yachts, using brands like Sunbrella and Nassimi.

Leave a Reply