The Day a Ground Wire Almost Ruined a Perfect Trip to the Keys

I’m Alex, and I’ve been wrestling with the electrical systems in marine engines in South Florida for about 15 years. You get to see it all down here: salt, sun, and vibration team up to murder boat parts. I remember a client, Javier, with a beautiful Sea Ray 340 Sundancer at Coconut Grove. He called me in a panic. His chartplotter was flickering, the engine gauges were acting possessed, and he was about to head to the Keys for a week.

He was convinced his whole system was shot. But after 20 minutes of tracing wires, I found it: a single, corroded ground wire, barely hanging on. A five-dollar fix saved his thousand-dollar vacation.

That’s the thing about the electrical systems in marine engines: they seem complex and intimidating, but most problems start small and simple. It’s the boat’s nervous system, and when it gets sick, everything goes haywire. But if you know what to look for, you can often be your own hero.

This guide isn’t a textbook. It’s what I’d tell you over a beer at the dock. We’ll cover the basics, how to spot trouble before it starts, and when it’s time to put down the tools and call a pro.

Table of Contents

The Heartbeat of Your Boat: Why This System Matters

Think of it this way: your engine has all the muscle, but the electrical systems in marine engines provide the brain and nerves. Without them, you’ve just got a very expensive anchor. From firing up the engine to making sure your navigation lights work after dark, it’s all on the electrical system.

Here in Florida, this system is in a constant street fight. Salt mist gets into connectors, engine vibration works terminals loose, and the heat tries to cook everything. That’s why proactive care isn’t just a good idea; it’s the only thing standing between you and a very bad day. A healthy electrical system is your number one safety feature.

These systems power everything:

- Starting: The massive jolt to get the engine turning.

- Charging: The alternator keeping your batteries from dying.

- Ignition: The spark that makes a gas engine go.

- Monitoring: All those gauges telling you the engine isn’t about to explode.

Most boats run on a basic 12V DC system, which is pretty straightforward. But newer boats? They have complex, networked electrical systems in marine engines that are a whole different beast. Knowing which you have is the first step.

The Usual Suspects: Key Components to Know

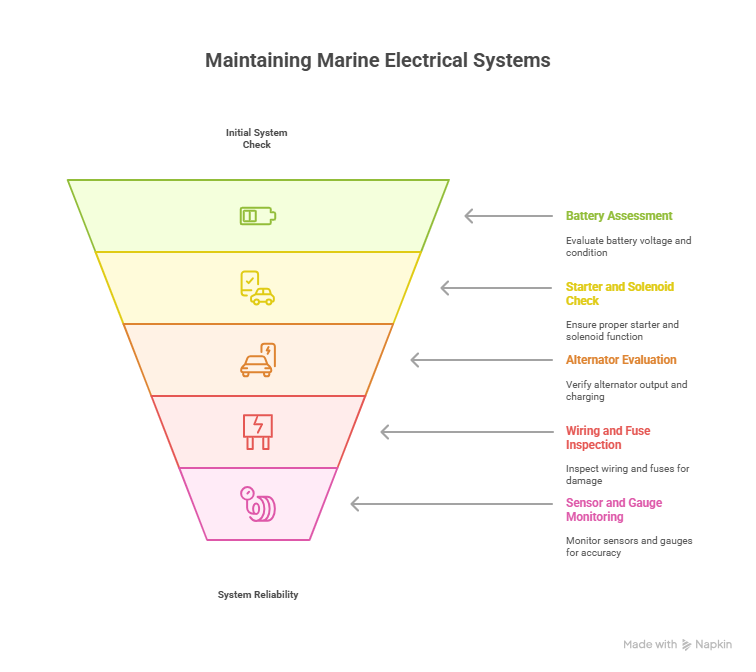

If you want to troubleshoot the electrical systems in marine engines, you need to know the players. It’s a small cast of characters, but they all have to work together.

- The Battery: This is your power reservoir. A fully charged 12V battery should sit around 12.6 volts. Anything less than 12.2V, and you’re in the danger zone. That slow, sad crank when you turn the key? That’s your battery crying for help.

- The Starter & Solenoid: When you turn the key, the solenoid—a heavy-duty relay—slams a connection shut, sending a tidal wave of amps to the starter motor. That “click-click-click” of a no-start? That’s often the sound of a solenoid not getting enough juice or giving up the ghost.

- The Alternator: This is the workhorse. Once the engine is running, the alternator recharges the batteries. With the engine running, you should see 13.5 to 14.5 volts at your battery terminals. If you don’t, your alternator is slacking off, and you’re running on borrowed time.

- Wiring, Fuses, and Breakers: This is the nervous system itself. I’ve pulled more green, crusty automotive wire out of boats than I can count. Don’t do it. Use only marine-grade, tinned-copper wire. Fuses and breakers are your sacrificial lambs—they blow to protect more expensive parts.

- Sensors and Gauges: These are your early-warning system. They tell you the oil pressure, engine temp, and RPMs. When a gauge acts funny, listen to it. It’s trying to tell you something before it becomes a big, expensive problem.

Safety First: The Rules I Live By

Before you even think about touching a wire on a boat, you need to get your head right about safety. Electrical systems in marine engines have a nasty habit of biting back if you don’t respect them.

The Golden Rule: Kill the power. Completely. Flip the main battery switch off. Then, go to the battery and physically disconnect the negative terminal first, then the positive. This prevents any stray sparks, which, near fuel fumes, is how boats end up on the evening news.

And wear gloves and eye protection. I know it seems like overkill, but an exploding battery or an accidental short can ruin your day, or your eyesight.

Troubleshooting Like a Mechanic: A Simple Game Plan

When I get a call about a wacky electrical issue, I don’t start with complex diagnostics. I start with my eyes and nose. After years of this, you see the same patterns. Corrosion is public enemy number one for electrical systems in marine engines.

I put together a little cheat sheet based on jobs I’ve done right here in Miami. It covers most of what you’ll run into.

| Symptom You See | My First Guess | What It Usually Costs (Miami) |

|---|---|---|

| Single “click,” no crank | Low battery or bad solenoid connection | $50 (cleaning) – $250 (new solenoid) |

| Slow, lazy engine crank | Dying battery or corroded cables | $200 (cables) – $500 (new battery) |

| Gauges are all dead | A blown main fuse or bad ground wire | $10 (fuse) – $200 (tracing a wire) |

| Lights dim when engine is running | Your alternator is failing | $400 – $900+ (alternator replacement) |

Start with the simple stuff:

- Look: Check battery terminals for green or white crust. Look for loose wires or melted insulation.

- Test: Put a multimeter on the battery. Is it charged?

- Check Fuses: Pull the fuses. Is one blown? Always replace it with the same amp rating. Never go bigger.

This simple process will solve 80% of the problems with electrical systems in marine engines.

Keeping Me Away from Your Boat: Proactive Maintenance

Want to avoid calling a mechanic like me? A little proactive care goes a long way. Think of it as sunscreen for your connections.

- Seasonally: Clean your battery terminals with a wire brush. Coat them with dielectric grease.

- Regularly: Check that all connections you can see are tight. Wiggle them. Nothing should move.

- Always: Use marine-grade parts for any repair. The extra few bucks for tinned wire and heat-shrink connectors will save you a fortune down the road.

This isn’t complicated stuff, but it’s what separates a reliable boat from one that’s always having issues with its electrical systems in marine engines.

FAQ: Quick Answers I Give at the Dock

Why do my lights flicker randomly?

Nine times out of ten, it’s a loose or corroded ground wire. Start tracing your grounds from the battery.

Can I use cheaper car parts on my boat’s engine?

Don’t do it. Just don’t. Automotive parts aren’t built to resist corrosion or to be ignition-protected for use around fuel vapors. It’s dangerous and will fail quickly.

What’s that green crust on my battery terminals?

That’s copper sulfate—a.k.a. corrosion. It’s a sign of a bad connection or leaking battery acid. Clean it off immediately with a baking soda and water solution, and protect the terminals.

How often should I really check my electrical system?

Every time you leave the dock, take a 10-second glance at your voltmeter. It’s the easiest health check for the electrical systems in marine engines. A full inspection should be done at least twice a year.

Is it safe to do my own electrical work?

It is, IF you know what you’re doing and you ALWAYS disconnect the power first. If you’re not 100% confident, especially with anything related to charging circuits or inverters, call a professional.

The Bottom Line: Alex’s Final Word

Look, the electrical systems in marine engines don’t have to be a black box of mystery. At the end of the day, it’s just about making sure the juice can get from point A to point B without something stopping it.

If you remember nothing else, remember this:

- Corrosion is the Enemy: Clean connections are happy connections.

- Safety Isn’t Optional: Always kill the power before you start wrenching.

- Start Simple: Most problems are simple. Check your battery and fuses first.

- Use the Right Parts: Marine-grade isn’t a suggestion; it’s a requirement.

- Know Your Limits: There’s no shame in calling a pro. It’s cheaper than replacing a fried ECU or, worse, causing a fire.

Take care of your boat’s electrical system, and it will take care of you. Now go enjoy the water.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified. I’ve diagnosed and repaired hundreds of electrical systems in marine engines, from simple wiring faults on center consoles to complete rewires on sportfishers at marinas like Dinner Key and Bahia Mar.

Leave a Reply