Quick Tips

- Sailboat rigging installation is a crucial task for ensuring the safety and performance of your vessel

- Proper material selection, installation techniques, and tuning are essential for a successful rigging upgrade

- Working with experienced professionals can help ensure a seamless and safe rigging installation process

- Regular inspections and maintenance are key to extending the lifespan of your sailboat’s rigging system

[BUTTON: Find Sailboat Rigging Installation Services near you]

Introduction

As an avid sailor, I understand the importance of maintaining a reliable and well-tuned standing rigging system on your sailboat. The standing rigging, which includes the masts, stays, shrouds, and forestays, plays a crucial role in ensuring your vessel’s structural integrity and overall performance. Over time, even the most robust rigging can succumb to the relentless forces of nature, making it necessary to upgrade or replace these vital components. In this comprehensive manual, I’ll guide you through the process of sailboat rigging installation, sharing valuable insights and best practices gleaned from years of experience on the water.

Boat Repair Shop: Navigating the Costs of Sailboat and Yacht Hull Maintenance

Sail Repair Kit: A Step-by-Step Guide to Sailcloth Repair and Restoration

Understanding Your Sailboat’s Standing Rigging

Before embarking on any sailboat rigging installation project, it’s essential to have a thorough understanding of the various components that make up your vessel’s standing rigging. The mast is the central pillar that supports the sails and rigging, while the stays and shrouds provide lateral support and tension. The forestay, on the other hand, is responsible for keeping the mast upright and preventing it from falling backward.Each of these components is subjected to immense loads and stresses, making it crucial to select the appropriate materials and follow proper installation techniques to ensure their longevity and reliability. Familiarize yourself with the specific terminology and functions of each component to better understand the upgrade process and make informed decisions.

Assessing the Need for a Rigging Upgrade

Determining when it’s time to upgrade your sailboat’s standing rigging is a critical step in the process. Regular inspections by a qualified rigger or marine surveyor can help identify any signs of wear, corrosion, or damage that may compromise the integrity of your rigging system.Common indicators that a sailboat rigging installation is necessary include excessive wire fatigue, deformation of rod rigging, or visible cracks or delamination in composite components. Additionally, if your sailboat has undergone significant modifications or upgrades, such as the installation of a taller mast or larger sails, it may be necessary to upgrade the standing rigging to accommodate the increased loads.

Professional Repair Facility: Top Questions About Maintaining Your Boat’s Hull

Choosing the Right Materials for Sailboat Rigging Installation

When it comes to upgrading your sailboat’s standing rigging, you have several material options to choose from, each with its own advantages and disadvantages. Stainless steel wire rigging is a popular and cost-effective choice, but it can be susceptible to corrosion and fatigue over time. Rod rigging, made from solid stainless steel rods, offers superior strength and resistance to fatigue but is more expensive than wire.For those seeking the ultimate in performance and durability, composite rigging made from high-strength fibers like carbon or aramid is an excellent option, albeit at a higher cost. Consult with a knowledgeable rigger or sailmaker to determine the best material choice for your specific needs, taking into account factors such as your sailing conditions, budget, and performance requirements.

| Rigging Material | Advantages | Disadvantages |

|---|---|---|

| Stainless Steel Wire | Cost-effective, traditional | Susceptible to corrosion and fatigue |

| Rod Rigging | Superior strength and fatigue resistance | More expensive than wire |

| Composite Rigging | High strength, lightweight, corrosion resistance | Most expensive option |

It’s also important to consider the compatibility of the new materials with your existing rigging components and hardware. Mixing different materials or using incompatible fittings can lead to galvanic corrosion or premature failure, compromising the integrity of your entire rigging system.

Sailboat Rigging Services: Navigating the Costs of Upgrading Your Vessel’s Rigging System

Sailboat Rigging Installation: Step-by-Step Process

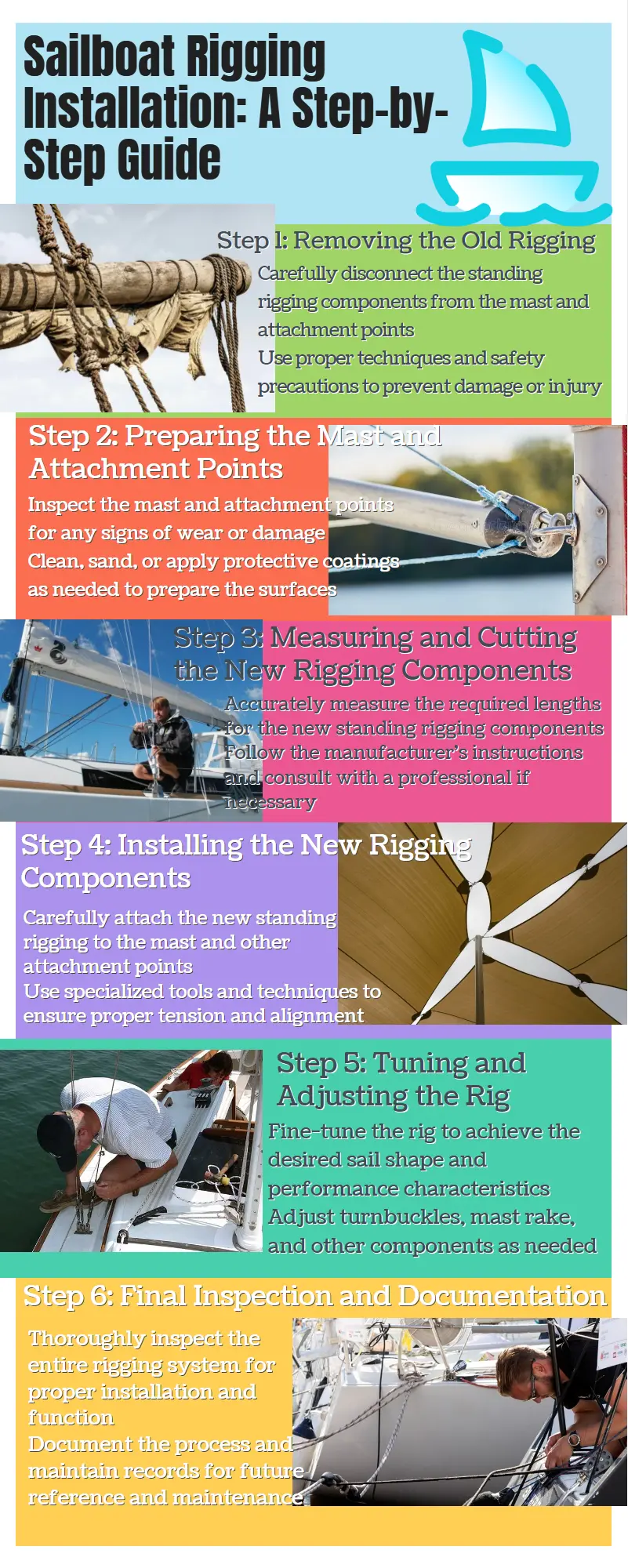

Once you’ve selected the appropriate materials, it’s time to begin the sailboat rigging installation process. This typically involves the following steps:

Removing the Old Rigging

This may involve unstepping the mast or disconnecting the rigging from the attachment points. Proper techniques and safety precautions should be followed to prevent damage or injury.

Preparing the Mast and Attachment Points

Inspect the mast and attachment points for any signs of wear or damage, and address any issues before proceeding with the installation. This may involve cleaning, sanding, or applying protective coatings.

Measuring and Cutting the New Rigging Components

Precise measurements are crucial to ensure a proper fit and optimal performance. Follow the manufacturer’s instructions and consult with a professional if necessary.

Installing the New Components and Tensioning the Rigging

This step requires specialized tools and techniques to ensure the correct tension and alignment of the rigging components. Improper tensioning can lead to premature failure or performance issues.

Tuning and Adjusting the Rig

Once the new rigging is installed, it’s essential to fine-tune and adjust the rig to achieve the desired sail shape and performance characteristics. This may involve adjusting turnbuckles, tweaking the mast rake, or making other minor adjustments

Throughout the sailboat rigging installation process, it’s crucial to follow the manufacturer’s instructions and industry best practices to ensure the safety and longevity of your new standing rigging system. Proper documentation and record-keeping can also be helpful for future reference and maintenance purposes.

Seeking Professional Assistance

While experienced and knowledgeable sailors may be able to tackle a sailboat rigging installation themselves, it’s often recommended to seek the assistance of a professional rigger or sailmaker, especially for larger or more complex rigs. These professionals have the necessary expertise, tools, and equipment to ensure a proper and efficient installation, minimizing the risk of errors or safety hazards.

[CATALOG_LINK: Find Sailboat Rigging Installation Services near you (Boat Repair and Maintenance)]

Maintaining and Inspecting Your Sailboat’s Rigging

Even after a successful sailboat rigging installation, it’s crucial to maintain a regular inspection and maintenance schedule to ensure the longevity and performance of your new rigging system. Regular inspections can help identify any potential issues early on, allowing you to address them before they become more significant problems.

Yacht Riggers Near Me: Common Questions About Sailboat Rigging Replacement

Conclusion

By following the guidelines outlined in this comprehensive manual, seeking professional assistance when necessary, and adhering to a regular maintenance schedule, you can ensure that your sailboat’s standing rigging is upgraded to the highest standards, providing you with a reliable and high-performing vessel for many years to come.

[BUTTON: Find Sailboat Rigging Installation Services near you]

Additional Resources

- Wood Sailboat Restoration: Navigating the Costs of Reviving Classic Wooden Sailing Vessels

- Sailboat Rigging Replacement: A Sailor’s Guide to Repairing Sailboat Hulls

- Sail Repair Service: Top Queries on Fixing and Maintaining Sails

[CATALOG_LINK: Browse Sailboat Rigging Installation Services in your area (Boat Repair and Maintenance)]