I’ve been patching up boats in South Florida for over 15 years, and cracks in aluminum hulls are one of those issues that pop up way too often—especially after a rough day off Biscayne Bay or banging into a dock at Bahia Mar. How to repair crack in aluminum boat isn’t rocket science, but it can go wrong fast if you don’t assess it right. I’ve seen owners slap on a quick patch only to have it fail mid-trip, turning a fun outing into a tow job. Let me break this down like I’d chat about it at Dinner Key Marina—starting with inspection, when to DIY or call a pro, and the fixes that actually hold. We’ll get into how to repair crack in aluminum boat step by step, drawing from jobs I’ve done on everything from Jon boats to fishing rigs.

Table of Contents

Pre-Repair Assessment: Inspecting the Crack and Choosing Your Strategy

Before you even think about tools, stop and really look at that crack. How to repair crack in aluminum boat starts with figuring out if it’s a minor annoyance or a hull-killer. I remember last summer, a guy named Ray brought his Alumacraft to Coconut Grove—thought it was just a hairline from a bump, but it spidered out under stress. We used a dye penetrant kit to reveal the full length, and it turned out to be a $800 structural fix. Drives me nuts when folks skip this and end up with leaks that could’ve been caught early.

Identify the Crack’s True Nature

Cracks aren’t all the same, and knowing the type saves you headaches. How to repair crack in aluminum boat depends on whether it’s structural or surface-level. A surface crack on a seat bracket? That’s fixable with epoxy. But if it’s on the transom or chine, that’s compromising the whole boat—I’ve seen those lead to full hull failures in rough waters off Stiltsville. Stress cracks often start at rivets from flexing, while impact ones come from hits. To see the real extent, grab a dye penetrant kit—it’s cheap and shows hidden ends. I carry one in my truck; saved a client’s Boston Whaler from a botched DIY last June.

Match the Repair to the Reality

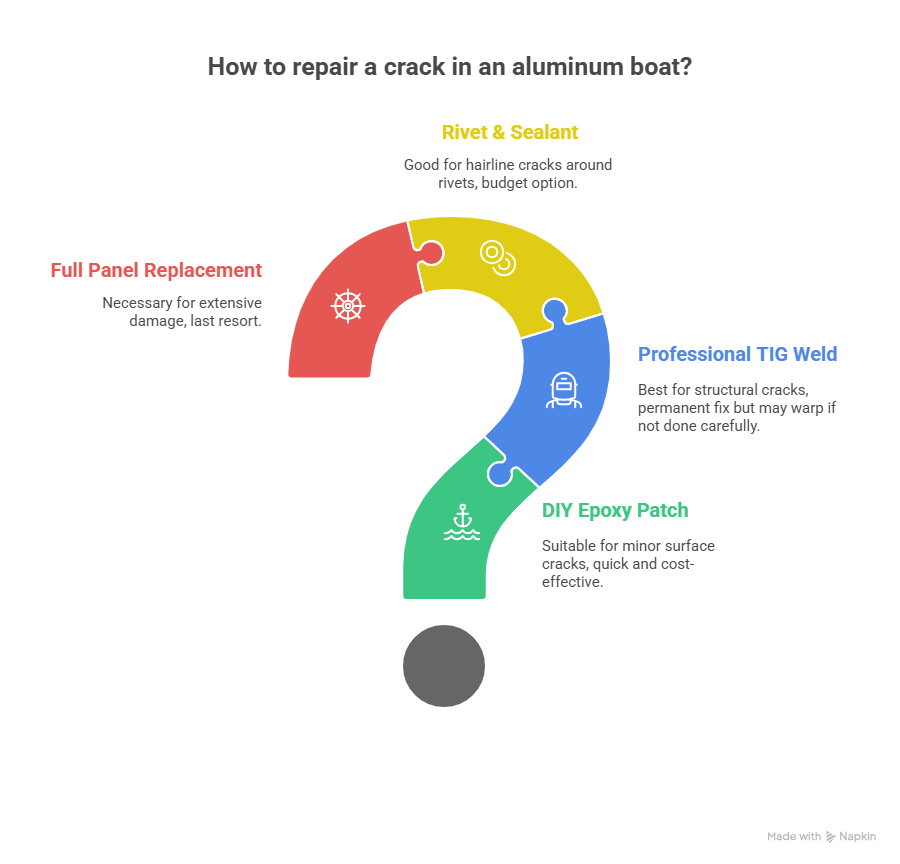

Once you’ve got the crack’s story, pick your fight. How to repair crack in aluminum boat boils down to location, your skills, and wallet. A submerged hull crack needs tough handling—more than a topside one. If you’re handy with a welder, great; otherwise, epoxy or patches work for small stuff. Time-wise, a pro weld is quick but costs $50–$100 for basics, while DIY takes curing time. I put this table together from repairs I’ve seen in Miami—helps compare options based on real jobs.

| Repair Strategy | Best For | Average Cost (South Florida) | My Experience Notes |

|---|---|---|---|

| DIY Epoxy Patch | Minor surface cracks, non-structural | $20–$100 | Quick for small leaks—held on a Jon boat for two seasons, but not for stress areas. |

| Professional TIG Weld | Structural cracks on transom/keel | $50–$800 | Permanent fix—did one on a SeaArk last fall, no issues since. Warps if not careful. |

| Rivet & Sealant | Hairline around rivets, budget option | $30–$200 | Good for accessible spots—saved a guy’s weekend, but check yearly in salt. |

| Full Panel Replacement | Extensive damage, multiple cracks | $500–$2,000 | Last resort—rebuilt a chine on a Whaler at Bahia Mar, tough but worth it. |

Be real about your limits—I’ve learned the hard way that forcing a DIY on a bad crack just leads to repeats.

When to Skip the DIY and Call a Professional

Look, I love a good DIY, but how to repair crack in aluminum boat sometimes means knowing when to hand it off. Some cracks are red flags that scream “pro needed.” I had a client, Javier, try patching a transom crack himself—ended up with a soggy hull and a $1,200 bill when it failed off Key Biscayne. It’s not about ego; it’s about safety. A botched job isn’t just messy— it could sink you.

Red Flags: Signs You Need an Expert

Spot these, and don’t touch it yourself. How to repair crack in aluminum boat goes pro for critical spots like the transom, keel, or ribs—failure there is catastrophic. Extensive spidering, dents, or wide gaps? Same deal. If you’re unsure, better safe. I’ve seen “small” cracks turn into hull breaches in Miami’s choppy waters—always err on calling in help.

Working with a Professional Welder

Finding the right welder isn’t hard—look for marine aluminum specialists with boat portfolios. I recommend ABYC-certified folks; they’ve handled the thin metal without warping. Quotes are easy: small cracks start at $50–$100, giving peace of mind. Last July, I referred a buddy to one at Dinner Key—his repair held through hurricane season. Ultimately, how to repair crack in aluminum boat professionally ensures it’s done right, letting you focus on fishing, not fixes.

Wrapping It Up

How to repair crack in aluminum boat boils down to smart assessment and no shortcuts. I’ve patched hundreds, and the ones that last are those diagnosed properly—whether it’s a quick epoxy or a full weld. I learned early on, after a lazy rivet job popped on my own boat, that rushing costs more in the long run. If you’re dealing with one: inspect thoroughly, match the fix, and call a pro if it’s structural. Your aluminum hull will thank you, outlasting the docks at Coconut Grove.

FAQ – Quick Answers from the Dock

Folks hit me up with these questions all the time at the marina, so here’s my straight-shooting take from years of fixes. No BS, just what works.

How do I know if a crack is structural?

Tap around it—if it’s on transom or keel and feels weak, it’s structural. How to repair crack in aluminum boat like that? Pro weld, no question—saw one ignored that led to a tow last summer.

Can I use epoxy for any crack?

Fine for surface ones, but not submerged stress cracks. I tried once on a chine—failed in a month. Stick to pros for how to repair crack in aluminum boat in tough spots.

What’s the cheapest way to fix a small crack?

Sealant and rivets, around $30. But test with dye first. Helped a client at Bahia Mar save bucks, but it won’t last forever in salt.

How long does a weld repair take?

A day for small ones, if accessible. I’ve seen pros knock out how to repair crack in aluminum boat in hours—cure time’s the wait.

Should I inspect after every trip?

Yeah, especially in Florida salt. Quick check prevents big issues—caught a hairline on my rig off Stiltsville before it grew.

Is TIG better than MIG for aluminum?

TIG for precision on thin hulls; MIG’s faster but riskier. Depends on the crack—I’ve used both for how to repair crack in aluminum boat jobs.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified, with 200+ repairs on cracked aluminum boats under my belt. From fixing hairline stress cracks on Alumacrafts to full structural welds on Boston Whalers and SeaArks, I’ve handled them all at marinas like Dinner Key and Bahia Mar, ensuring hulls stay intact against our harsh saltwater and humid conditions.

Leave a Reply