How to Repair Damaged Fiberglass Boat Hull – My No-Nonsense Guide

I’ve been wrenching on boats down here in South Florida for over 15 years, and let me tell you, nothing ruins a weekend faster than that gut-wrenching crunch against a hidden rock or dock piling. How to repair damaged fiberglass boat hull is a question I get all the time at places like Dinner Key Marina—folks pulling up with gouges that look like a shark took a bite. It’s not as scary as it seems, though. If you prep right and use the good stuff, you can make that hull strong again, sometimes stronger than before. Yeah, I’ve patched hundreds, from little runabouts to big center consoles, and most hold up fine against our humid, salty mess. Let me break it down like I’d chat with you over a beer at Bahia Mar—starting with the basics, ’cause rushing into resin is a recipe for redo.

Last summer, a guy named Javier hauled his Boston Whaler over to Coconut Grove after scraping it on some coral off Key Biscayne. The crack was about 18 inches long, spiderwebbing out—classic impact damage. He was freaking out about the bill, but I showed him how to repair damaged fiberglass boat hull himself for under $200 in materials. We got it done in a weekend, and he’s still cruising without a leak. Stories like that keep me going, but they all start with getting your head right and your tools lined up.

Table of Contents

Why Fiberglass Hulls Crack and How to Spot the Real Damage

Before you even think about mixing epoxy, you gotta understand what you’re dealing with. Fiberglass hulls are tough, but they ain’t invincible—especially in Miami’s choppy bays where hidden debris lurks. How to repair damaged fiberglass boat hull starts with a good inspection. I always grab my flashlight and tap around the area with a coin or screwdriver handle. If it sounds hollow or dull, you’ve got delamination underneath, not just surface scratches. Weird? Not really, it’s from water sneaking in and weakening the layers.

Take Carla’s case last June at Fort Lauderdale—she thought her Sea Ray had a minor ding from a bad docking, but when I probed it, the core was mushy from water intrusion. We ended up cutting out a 2-foot section. That’s why I say: measure the damage first. Use a moisture meter if you can borrow one—anything over 20% means rot, and your repair needs to go deeper. How to repair damaged fiberglass boat hull without checking that? You’re asking for trouble, like patching over wet wood. I learned that the hard way back in the ’90s on my dad’s old Grady-White—epoxy popped off after one rainy season.

The usual suspects? Impacts from rocks or docks create starburst cracks; gelcoat blisters from poor layup or age; and stress fractures from flexing in rough water. Down here off Stiltsville, UV and salt chew through unprotected spots fast. If it’s below the waterline, assume it’s structural—don’t mess around. I snap photos of every job before starting; helps track what I did if issues pop up later.

Gearing Up: Tools and Safety Gear That Actually Matter

Alright, let’s talk kit. How to repair damaged fiberglass boat hull without the right stuff is like trying to fish without bait—a waste. I keep my truck loaded for mobile jobs, and here’s what I grab first. Safety-wise, don’t skimp—fiberglass dust is nasty, itches like hell, and the fumes from resin can knock you out. I wear a full-face respirator with organic vapor cartridges every time; saved my lungs on a big repair at Key Biscayne where the wind was blowing everything back at me.

Gloves? Nitrile, thick ones—latex melts with epoxy. Goggles, long sleeves, and a disposable suit if it’s a dusty grind. Yeah, I look like a hazmat guy, but better that than hives. For tools, an angle grinder with 36-grit discs is my go-to for beveling edges—aim for a 12:1 taper, meaning 12 inches wide for every inch deep. A Dremel for tight spots, and don’t forget mixing cups, spreaders, and acetone for cleanup. I cut open old filters sometimes to check for contaminants, but that’s a tangent—keeps things clean.

Materials? Epoxy resin for strength—West System or MAS, thickened with colloidal silica for fairing. Fiberglass cloth in 6-10 oz weights, and gelcoat to match. Polyester is cheaper for topside stuff, but in our humid marinas, epoxy holds better. Last July, Ray at Bahia Mar tried polyester on his Mako’s hull crack—peeled in two months. Switched to epoxy, and it’s solid. How to repair damaged fiberglass boat hull on a budget? Start with epoxy kits from marine stores; they’re worth it.

I put this table together from fixes I’ve done in Miami—compares resins and when to use ’em. Helps decide without guessing.

| Resin Type | Best For | Average Cost | My Take from South Florida Jobs |

|---|---|---|---|

| Epoxy | Structural, below waterline | $50–$150 per kit | Tough as nails, no blush—saved a guy’s Contender from sinking after a prop strike. |

| Polyester | Cosmetic, above waterline | $20–$60 per kit | Cheap and quick, but shrinks in heat—failed on a hot day at Dinner Key. |

| Vinylester | Mid-level strength, some water exposure | $30–$80 per kit | Decent hybrid, but I stick to epoxy for anything serious off Stiltsville. |

Step-by-Step: Prepping and Grinding the Damage

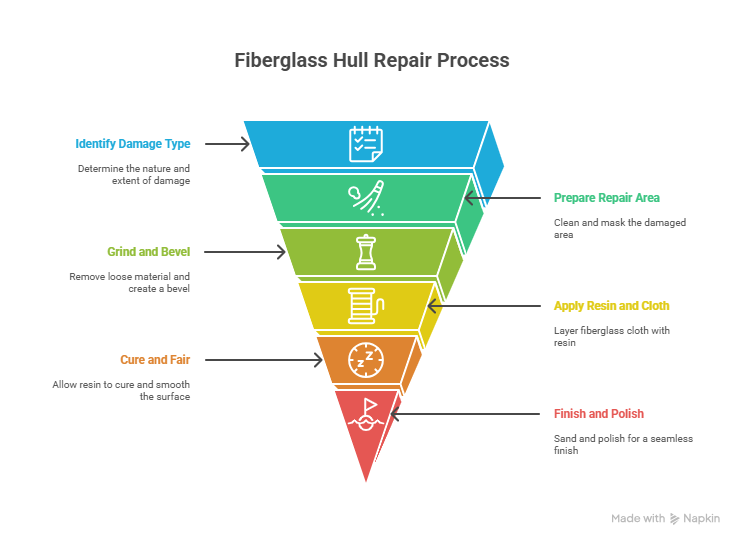

Prep is where 80% of how to repair damaged fiberglass boat hull happens. Skip it, and you’re back to square one. First, clean the area with soap and water, then acetone to degrease. Mask off around it—tape saves headaches. Now grind: use that angle grinder to remove loose material, beveling out to create a scarfed edge. I aim for 0.5-inch depth on small gouges, wider on big ones.

Carlos brought his Pursuit in after hitting a manatee zone marker—hull gouged deep. We ground it back until we hit solid laminate, about 1/4-inch runout. Dust everywhere, but with the respirator, no issue. If there’s core (like balsa or foam), cut it out and dry thoroughly—fans or heat lamps for days in our humidity. How to repair damaged fiberglass boat hull with wet core? You can’t; it’ll rot again. I once rushed one and had to redo it—$500 lesson.

Tangent: I always check for osmotic blisters here. Poke ’em; if vinegar smell, it’s bad. Flush with water, dry, then proceed.

Laying Up the Patch: Resin, Cloth, and Fairing

Now the fun part—mixing and applying. How to repair damaged fiberglass boat hull means layering fiberglass cloth wet with resin. Cut patches oversized, smallest first, building up. Wet out on plastic, then press into the bevel. Roll out bubbles with a grooved roller—air pockets weaken it. For a 12-inch crack, I use 3-5 layers, overlapping 2 inches.

Sofia at Coconut Grove had a spider crack on her Regulator from trailer damage. We laid epoxy-soaked 1708 biax cloth, let it cure overnight. Next day, fair with thickened epoxy—sand to shape. Gelcoat topper, color-matched. She was back on the water in a week, no visible scar. How to repair damaged fiberglass boat hull like that? Patience—rush the cure, and it warps.

If it’s cosmetic, polyester filler works, but for strength, epoxy. I add cabosil for thickness—peanut butter consistency. Cure times? 24 hours min, but in Florida heat, it sets faster—check with a fingernail test.

Finishing Touches and Prevention Tips

Sanding and polishing seal the deal. Start with 80-grit, work to 400, then compound for shine. Wet sand for gelcoat to avoid dust. How to repair damaged fiberglass boat hull and make it invisible? Buffing compound and a variable-speed polisher—I’ve matched factory finishes on Yamahas that way.

Prevention? Wash after every use, wax regularly, and check for dings early. In our marinas, sacrificial anodes help if there’s metal nearby, but fiberglass is more about UV protection. Half my calls could be avoided with a quick hose-down.

Ronnie’s story last fall: His Key West hull cracked from improper storage. Fixed it with the full layup—$400 instead of shop’s $2k. How to repair damaged fiberglass boat hull DIY? Follow this, and you’re golden.

Wrapping It Up – No Shortcuts, Just Solid Fixes

How to repair damaged fiberglass boat hull ain’t rocket science—it’s method and elbow grease. I’ve seen rushed jobs fail in Biscayne Bay waves, but proper preps last years. Remember Javier’s Whaler? Still going strong. If you’re staring at a gouge, grab that grinder and start small. Saves money, builds skills. But if it’s over your head, call a pro—better safe than swimming.

FAQ – Stuff Folks Ask Me at the Marina

Quick hits from my dockside chats. No BS, just experience.

What’s the biggest mistake in how to repair damaged fiberglass boat hull?

Rushing prep—dirty surfaces mean weak bonds. Seen it sink a buddy’s repair off Key Biscayne.

Epoxy or polyester—which for below waterline?

Epoxy every time. Polyester absorbs water here in Florida—leads to blisters.

How long to let it cure?

24-48 hours, test with sandpaper. Heat speeds it, but don’t force.

Can I paint over the repair?

Yeah, after fairing. Match marine paint—I’ve used Awlgrip for seamless jobs.

Tools for a beginner?

Grinder, respirator, epoxy kit. Start small, like a gelcoat chip.

When to call a pro?

If it’s structural or you’re unsure—better than a botched how to repair damaged fiberglass boat hull attempt.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified, with 200+ fiberglass hull repairs under my belt. From patching Boston Whalers and Sea Rays to full laminate rebuilds on Makos and Regulators, I’ve handled impacts, blisters, and stress cracks at marinas like Dinner Key and Bahia Mar, ensuring boats stay strong against our corrosive saltwater environment.

Leave a Reply