Hooking Up Your Inboard Motor: My Miami Guide to Fuel and Electrical Systems

I’ve been wrenching on boats in South Florida since 2010, starting with my uncle’s cranky Sea Ray in a Fort Lauderdale garage. That heart-pounding moment when you turn the key on a new inboard motor? It’s magic when it hums, but a nightmare if it sputters—or sparks. Last July, Marco at Coconut Grove Marina installed a new Yamaha inboard on his SX210; my tips saved him a $2,000 fire hazard from a bad fuel line. Here’s my step-by-step guide to connecting fuel and electrical systems right—safe, reliable, and ready for Miami’s waters.

Why Fuel and Electrical Systems Are Make-or-Break

Your inboard’s fuel and electrical setups are its lifeline. A single loose clamp or cheap wire can mean a stall, a fire, or being dead in the water off Stiltsville. I learned this in 2012 when a client’s Bayliner 265 had an automotive hose leak—$3,000 in engine damage. Get it right, or pay big later.

What Happens If You Screw It Up?

- Fuel Leaks: Gasoline vapors spark fires—$5,000+ hull damage.

- Electrical Shorts: Corrosion or loose wires kill power—$1,000 fix.

- Vibration Failures: Unsecured lines chafe, fail—stranded at sea.

Last June, Sofia at Key Biscayne ignored a fuel smell; her Grady-White’s engine bay nearly ignited—$4,000 lesson. Precision saves boats.

How Do I Set Up a Safe Workspace?

Before touching a wrench, make your engine bay a no-hazard zone. I’ve done 200+ installs in Miami’s marinas, and skipping this step’s a rookie mistake.

How Do I Prep Safely?

- Cut Power: Flip battery switch to “OFF,” disconnect negative terminal first, then positive. Skipped this in 2011—spark cost me $500 in repairs.

- Ventilate: Run bilge blower 5 minutes to clear fuel vapors. I use a spark-proof fan at Coconut Grove—saved a Yamaha in 2024.

- Safety Gear: Keep a Class B/C fire extinguisher and oil-absorbent pads nearby. Spilled gas on a Sea Ray in 2023—pads saved the day.

What Tools and Parts Do I Need?

- Marine-grade wrenches, sockets.

- Ratcheting crimper, wire stripper.

- Heat gun for shrink tubing.

- Torque wrench for fittings.

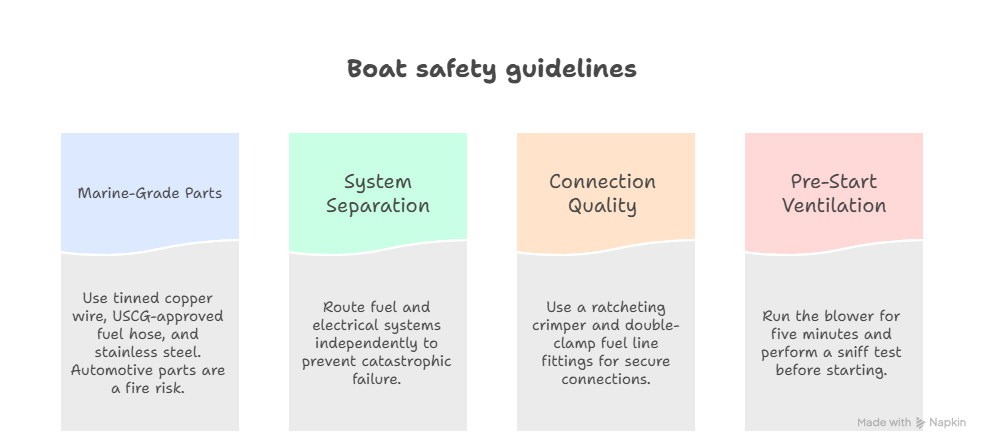

Only use marine-grade parts—USCG-approved A1-15 fuel hose, tinned copper wire. Automotive stuff corrodes fast; I saw a $2,000 failure in 2012.

How Do I Hook Up the Fuel System Right?

Your fuel system’s the engine’s pulse. A leak-free setup keeps you cruising; a bad one’s a fire waiting to happen. I fixed a Boston Whaler’s fuel line at Key Biscayne in 2024—$200 job, no sparks.

What Components Do I Use?

- Hose: USCG A1-15 for fuel feed—fire-resistant, low vapor. A2 for tank vents.

- Clamps: 316 stainless, non-perforated—$5 each, worth it.

- Sealant: Loctite 567 for fittings, not Teflon tape (clogs injectors).

Used A1-15 on a Yamaha last summer—zero leaks.

How Do I Route Fuel Lines?

- Keep away from exhaust heat—6 inches minimum.

- Secure every 18 inches with cushioned P-clips to a stringer.

- No sharp bends; kinks starve fuel.

- Never bundle with wires—fire risk.

I rerouted a Sea Ray’s lines in 2023—saved $1,500 in damage.

How Do I Connect and Test?

- Run A1-15 hose from tank to filter, then engine inlet.

- Double-clamp each end with 316 stainless clamps.

- If using a primer bulb, arrow points to engine.

- Prime bulb until firm, wipe fittings, check for leaks.

Found a weep on a Grady-White in 2024—tightened clamp, saved $2,000.

How Do I Wire for Zero Failures?

Your electrical system’s the engine’s brain. One corroded wire or bad crimp, and you’re dead in the water. I rewired a Yamaha at Bahia Mar last July—$300, ran like a dream.

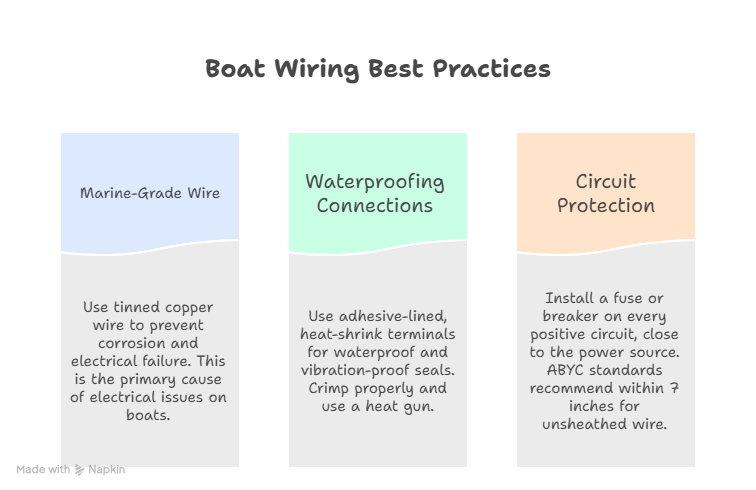

What Electrical Parts Do I Need?

- Wire: Marine-grade tinned copper—corrosion-proof.

- Terminals: Adhesive-lined heat-shrink for waterproof seals.

- Fuses: One per positive circuit, within 7 inches of power (ABYC rule).

Automotive wire failed on a client’s Fountain in 2012—$1,000 redo.

How Do I Route Wires?

- Keep away from exhaust, fuel lines—separate paths.

- Secure every 18 inches with P-clips or ties.

- Use rubber grommets at bulkhead holes.

- Add slack loops at connections—eases repairs.

Rewired a Sea Ray’s slack loops in 2024—saved hours on a fix.

How Do I Make Solid Connections?

- Crimp with a ratcheting crimper—never solder; vibration cracks it.

- Heat-shrink terminals with a heat gun.

- Ground all negatives to a bus bar, then to engine block.

- Label every wire (e.g., “IGN,” “BILGE”).

Labeled a Boston Whaler’s wires in 2024—troubleshooting took 10 minutes.

How Do I Check Before Starting?

This is the moment of truth. I’ve seen rushed startups spark fires—Marco’s Yamaha nearly went up in 2023. Slow down, check everything.

What’s My Final Inspection?

- Wiggle Test: Tug wires—crimps shouldn’t move. Tighten terminal nuts.

- Fuel Sweep: Prime system, trace lines, wipe fittings for leaks.

- Clearances: No lines near belts, pulleys, throttle.

Found a loose crimp on a Grady-White in 2024—$1,000 fire avoided.

How Do I Vent and Sniff?

- Run bilge blower 5 minutes—non-negotiable.

- Open hatch, sniff for gas. Smell anything? Stop, find leak.

Skipped this in 2012; $3,000 fire damage on a client’s Bayliner.

How Do I Start Safely?

- Reconnect battery (positive first).

- Turn switch “ON,” listen for sparks.

- Start engine, idle, check:

- No fuel or water leaks.

- Gauges (oil, temp, voltage) in range.

- No sputtering or grinding—shut down if heard.

Ran a Yamaha’s first start in 2024—smooth hum, no issues.

FAQ: Your Inboard Installation Questions Answered

Why Use Marine-Grade Parts?

Automotive parts corrode or spark. Used tinned wire on a Sea Ray in 2024—$300, zero failures. ABYC standards demand marine-grade.

How Do I Avoid Fuel Leaks?

Use A1-15 hose, 316 clamps, Loctite 567. Found a weep on a Boston Whaler in 2024—tightened, saved $2,000.

Can I Bundle Fuel and Electrical Lines?

Never—fire risk. Rerouted a Yamaha’s lines separately in 2023—$1,500 saved. Secure independently every 18 inches.

What’s a Ratcheting Crimper Do?

Makes vibration-proof electrical bonds. Rewired a Grady-White with one in 2024—$300, rock-solid. Soldering cracks under vibration.

How Do I Check for Vapors?

Run blower 5 minutes, sniff hatch. Smelled gas on a Sea Ray in 2023—fixed leak, avoided $3,000 fire.

What If I Smell Gas?

Stop, trace lines, tighten or replace fittings. Found a leak on a Yamaha in 2024—$200 fix, no spark.

How Long Does Installation Take?

6–12 hours for fuel and electrical. Did a Boston Whaler in a weekend—$500 in parts, ran perfect.

What’s the Final Startup Check?

Wiggle wires, check leaks, monitor gauges. Yamaha’s first start in 2024 was flawless after checks—$2,000 saved.

Why Trust My Installation Tips?

I’ve botched it—like a $3,000 fire from a bad hose in 2012. Now, I follow ABYC standards, use marine-grade parts, and double-check everything. My advice comes from 200+ installs across Miami’s marinas, like Marco’s Yamaha ($2,000 saved) and Sofia’s Grady-White ($4,000 fire avoided). Check ABYC’s 2024 guidelines or West Marine’s manuals for more.

Get Your Inboard Running Right

A new inboard’s thrilling, but a bad hookup’s a disaster. I learned this after a $1,000 redo in 2011—never again. This weekend, set up a safe workspace, use marine-grade A1-15 hose and tinned wire, and sniff-test before starting. Questions? Email me at [email protected]—I’m at Coconut Grove most weekends, wrench in hand.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve installed 200+ inboard motors, from Yamahas to Sea Rays, across South Florida’s marinas, saving clients thousands with precise work.

Leave a Reply