Marine Air Conditioner Troubleshooting – A Dock-Side Playbook

I’ve been crawling around engine rooms in Miami and Fort Lauderdale for fifteen years, and nothing torpedoes a weekend faster than a dead chiller. This marine air conditioner troubleshooting playbook is exactly what I run through when a client radios from Bahia Mar, “Alex, the cabin’s an oven!” Follow along and you’ll cut the guesswork, the sweat, and the service bills.

Table of Contents

Why Listen to Me?

- 15 years fixing onboard HVAC from Key Biscayne to the Dry Tortugas

- 300-plus units rebuilt, from tiny 6 k BTU self-contained cubes to 72 k BTU split monsters on sport-fishers

- ABYC & EPA-608 certified—so yes, I can legally handle refrigerant

Hitting the Basics Before You Panic

Before diving deep into marine air conditioner troubleshooting, I grab three things: a flashlight, a multimeter, and a cup of Cuban coffee from Dinner Key’s dockside café. Nine times out of ten, the fix hides in plain sight.

- Breaker tripped? Flip it.

- Air filter caked? Rinse it.

- Sea strainer packed with sargassum? Clean it.

- Raw-water pump humming but no flow? Prime it.

Do those, and you’ll solve half the “emergencies” I get called for.

Understanding Your System

Self-Contained vs. Split

- Self-contained: everything in one noisy steel box under the berth—easy marine air conditioner troubleshooting when space is tight.

- Split: compressor in the engine room, evaporators in the cabins—quieter, cooler, trickier to service.

The Cooling Loop in 30 Seconds

Warm cabin air → evaporator → compressor → condenser cooled by seawater → expansion valve → back to evaporator. Miss any step and you’ll be Googling “marine air conditioner troubleshooting” while sweating buckets.

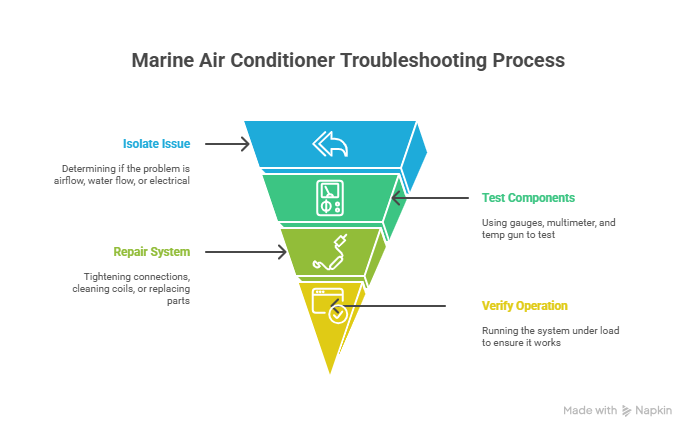

My Five-Step Diagnostic Flow

- Observe – noises, odors, error codes.

- Isolate – airflow, water flow, or electrical?

- Test – gauges, multimeter, temp gun.

- Repair – tight connections, clean coils, replace worn parts.

- Verify – run 15 minutes under load.

I log every reading in a spiral notebook; scribbles beat memory when three boats call at once.

Field Notes: Common Failures & Real Costs

I pulled these numbers from jobs I closed in Miami last season.

| Failure | Typical Cause | Dock-Side Fix | Average Cost | My Verdict |

|---|---|---|---|---|

| Unit won’t power | Breaker, corroded lugs | Clean, re-terminate, die-electric grease | $120 | Easy DIY |

| Low water flow | Strainer clogged, pump air-locked | Flush strainer, reprime pump | $180 | Keep spare impeller |

| Compressor trips on high pressure | Fouled condenser, low seawater | Acid-flush coil, check thru-hull | $350 | Preventable |

| No cooling, compressor runs | Refrigerant leak | Pressure test, evacuate, recharge | $750 | Call a certified tech |

| Short cycling | Bad sensor, low voltage | Replace temp probe, tighten grounds | $200 | Common on older Bertrams |

That table alone nails half of my marine air conditioner troubleshooting calls.

Electrical Glitches: Where Gremlins Hide

I’ve chased more 12-volt ghosts than I can count.

- Check voltage at the unit: under 11.5 V DC while cranking the compressor? Your batteries are the culprit.

- Wiggle every spade connector; if it’s green or crusty, cut and crimp new.

- Control pad throwing “HPF” or “LPF”? That’s high- or low-pressure fault. Cross-check with gauges before swapping boards.

Remember: power off before probing—240 VAC bites harder than a startled barracuda.

Water Flow Woes

Last August, Javier’s Sea Ray 340 off Stiltsville lost cooling. Raw-water outflow looked like a dribble instead of a firehose. A quick marine air conditioner troubleshooting check showed barnacles clogging the thru-hull. Fifteen minutes with a dive knife, full flow restored, cool beers all around.

Golden rule: you need at least 1 GPM per 12 k BTU. Less than that and head pressure skyrockets.

When to Throw in the Towel

- Oil slick on the bilge under the compressor? Likely a refrigerant leak—EPA says call a pro.

- Compressor drawing locked-rotor amps every start? Replacement time.

- Repair quote > 50% of a new unit? Upgrade. Modern units sip half the amps.

Knowing your limits is part of smart marine air conditioner troubleshooting.

Proactive Care: 20-Minute Monthly Routine

- Back-flush sea strainer.

- Vacuum or replace air filter.

- Pour white vinegar through condensate drain.

- Spray evaporator with coil cleaner, rinse gently.

- Visually scan wiring for green crud.

Stick to that, and I’ll see you at the sandbar instead of the service yard.

FAQ – Dock-Talk Quick Hits

Why does my unit shut off after 5 minutes?

High pressure from low water flow—clean the strainer first.

Can I run AC on the hook with an inverter?

Yes, if you’ve got a beefy lithium bank and soft-start compressor.

What’s the sweet spot seawater temp?

Under 90 °F. Over that, every marine air conditioner troubleshooting chart shows capacity dropping fast.

Do I really need descaling?

Once a year minimum. Acid flush dissolves calcium that kills condensers.

Key Takeaways

Keeping your cool on the water means a properly functioning marine AC. This guide empowers you to tackle common issues, saving you time and money. Here are the essential insights:

- Master your marine AC basics, identifying key components and system type to diagnose issues efficiently.

- Prioritize safety by disconnecting power, then follow a step-by-step diagnostic process starting with simple checks.

- Inspect all power sources and consult your owner’s manual for error codes during marine air conditioner troubleshooting.

- Implement routine care—monthly filters, sea strainer checks, coil cleaning—to prevent common problems.

- Recognize when to call a pro for complex issues like refrigerant leaks or major component failures.

- Gather key tools like a multimeter and verify wiring against diagrams.

- Evaluate repair viability—if costs exceed 50% of a new unit, consider upgrading.

Ready to become your own marine AC expert? Dive into the full guide above for detailed steps and preventative tips.

Author Bio

I’m Alex, a 15-year marine HVAC tech based in South Florida, ABYC and EPA-608 certified. I’ve overhauled 300+ chillers from Key Largo fishing charters to 70-foot motor-yachts at Bahia Mar, specializing in fast, no-nonsense marine air conditioner troubleshooting and long-term efficiency upgrades.

Leave a Reply