I’ve been elbows-deep in marine diesels for 15 years here in South Florida, and I can tell you one thing for sure: these engines are the heart of any serious vessel. They’re built like tractors, not sports cars—designed for pure, relentless torque. But that toughness doesn’t mean you can ignore them.

I’ll never forget a call I got a few years back. A guy with a beautiful 45-foot trawler was 30 miles offshore when his engine just… quit. No warning, just silence. It turned out to be a catastrophic failure caused by a slow, undetected coolant leak that he’d been ignoring for weeks. A simple hose clamp and a pressure test—a tiny part of a routine marine diesel engine repair check—could have saved him a $20,000 rebuild and a very scary tow back to shore.

That story is why I’m writing this. Proper marine diesel engine repair and maintenance isn’t just about fixing things. It’s about prevention. It’s about understanding the beast in your bilge so you can trust it when you’re miles from anywhere. Whether you’re a hands-on skipper or just want to speak the same language as your mechanic, this guide is for you.

Table of Contents

The Heart of Your Vessel: What Makes Marine Diesels Special

A marine diesel is a different animal from the engine in your truck. It’s designed to run under heavy load for hours, even days, on end. Everything is built heavier, tougher, and with the brutal marine environment in mind.

- The Fuel System: This is the engine’s lifeblood. High-pressure injectors and robust fuel pumps are precision instruments. They hate dirty fuel.

- The Cooling System: Diesels run hot. Their cooling systems, with heat exchangers and raw water pumps, are complex and absolutely critical. Overheating is the #1 killer of these engines.

- The Turbocharger: Many marine diesels have a turbo to boost power. It’s an amazing piece of engineering, but it needs clean oil and clean air to survive.

When you need a marine diesel engine repair, you have to use parts built for this world. Using a cheap automotive part is like putting bicycle tires on a semi-truck. It’s just not going to end well.

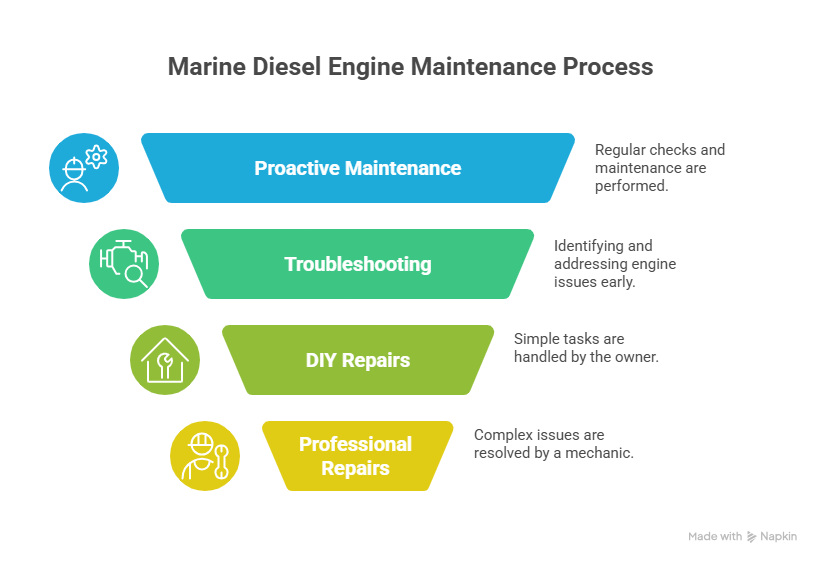

The Non-Negotiable Stuff: Proactive Maintenance

If you want your engine to last, you can’t just fix it when it breaks. You have to be proactive. This is the single most important part of avoiding a costly marine diesel engine repair bill.

- Oil Changes: This is non-negotiable. Follow the manufacturer’s schedule, typically every 100-200 hours. Clean oil is the cheapest insurance you can buy.

- Fuel Filters: I tell my clients to change their fuel filters religiously. A clogged filter will starve your engine of fuel and can cause all sorts of performance problems. It’s a simple, 20-minute job that can save you a huge headache.

- Cooling System Checks: Before every trip, check your coolant level and inspect your raw water strainer. A plastic bag sucked into your intake can overheat your engine in minutes. And that water pump impeller? Change it every year or two, whether it looks like it needs it or not.

When Your Engine Starts Talking to You: Troubleshooting

Your engine will almost always give you a warning before it fails. You just have to learn to listen. A new noise, a puff of strange-colored smoke, a gauge reading that’s a little off—these are clues.

- Fuel Problems: The engine is hard to start, smokes black, or lacks power. This is the first place I always look during a marine diesel engine repair diagnosis. It could be anything from a clogged filter to a failing injector pump.

- Overheating: The temperature gauge is climbing. This is an immediate, shut-it-down-now problem. Check your raw water intake and strainer first.

- Weird Noises: A new knock, a high-pitched whine, a grinding sound. These are all signs of mechanical trouble that need to be investigated by a professional right away.

DIY vs. The Pro: Know When to Call for Help

I love it when boat owners want to get their hands dirty. But a complex marine diesel engine repair is not the place to learn on the fly. Knowing your limits is crucial.

Here’s a quick table of what I think is DIY-friendly versus what needs a pro:

| Task | DIY or Pro? | My Take |

|---|---|---|

| Oil & Filter Change | DIY | Absolutely. Every owner should know how to do this. |

| Fuel Filter Change | DIY | Yes. Another essential skill. |

| Impeller Replacement | DIY (with manual) | Very doable for most, but can be in a tight spot. |

| Valve Adjustment | Pro | Requires specific tools and feel. Best left to a pro. |

| Injector or Pump Work | Pro | Definitely a professional job. This is a high-precision system. |

| Engine Rebuild | Pro | This is major surgery. Don’t even think about it. |

Finding a good mechanic is key. Look for someone who specializes in marine diesel engine repair, not just a general mechanic. Ask for references. A good tech is a partner in keeping your vessel safe.

FAQ: Questions I Get All the Time

How often do I really need a professional marine diesel engine repair service?

Besides the routine stuff you do, I recommend having a qualified tech give it a full inspection and tune-up once a year. They’ll spot things you might miss.

Why is marine diesel engine repair so expensive?

Two reasons: The parts are specialized and built to a higher standard, and the labor requires a unique skill set. You’re paying for expertise in an environment where failure is not an option.

Is a rebuild worth it?

It can be. A well-executed rebuild by a reputable shop can give your engine a whole new life for a fraction of the cost of a new one. But if there’s major internal corrosion or a cracked block, it’s probably time to repower.

What’s the biggest mistake owners make?

Ignoring the small stuff. A small drip from a hose, a gauge that reads a little funny, a slightly longer crank time. These are the whispers before the scream. Addressing them early is the key to avoiding a big marine diesel engine repair bill.

Can I use automotive oil or coolant?

No. Absolutely not. Marine engines operate under different loads and temperatures. Use only high-quality fluids specifically rated for marine diesel use.

The Bottom Line: My Final Advice

Taking care of your marine diesel is about peace of mind. It’s about knowing that when you push that start button, it’s going to fire up and get you home safely. If you take anything away from this, let it be this:

- Be Proactive: Maintenance isn’t a task, it’s a mindset. Stay ahead of problems.

- Use Quality Parts & Fluids: Your engine’s life depends on it. Don’t cheap out.

- Listen to Your Engine: It will tell you when it’s unhappy.

- Find a Good Mechanic: Build a relationship with a pro you trust for the big jobs.

- Safety First, Always: When working on your engine, be safe and be responsible with waste fluids.

A marine diesel is a long-term investment. With the right care and a solid marine diesel engine repair strategy, it will be the most reliable thing on your boat, ready to take you on any adventure you can dream of.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified in diesel engines. I live and breathe marine diesel engine repair, from routine maintenance on Yanmars and Volvos to full-blown rebuilds on classic Cats and Cummins engines. I’ve helped boaters at marinas like Bahia Mar and Dinner Key keep their vessels reliable and ready for the open water.

Leave a Reply