That Sound No Boater Wants to Hear

I’ve been wrenching on boats in South Florida for nearly two decades, and there’s a sound that makes every captain’s blood run cold: the reliable thrum of a diesel suddenly changing its tune. A cough, a sputter, or just… silence. I remember getting a frantic call from a guy named Javier on his Hatteras 53 out near Stiltsville. His port engine just gave up. That moment of panic is exactly why understanding marine diesel engine repair isn’t just a skill—it’s a necessity.

Your diesel engine is the heart of your boat. It’s a heavy-duty beast designed to handle saltwater, long hours, and keep you safe. But even the toughest Yanmar or Cummins needs respect and the right kind of care. Ignoring the little things, like a weird vibration or a puff of black smoke, is how small problems turn into huge, wallet-draining disasters far from shore.

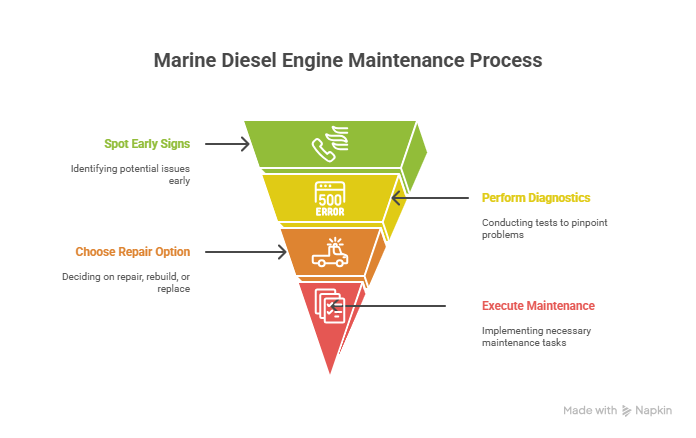

This guide is my brain dump—everything I’ve learned from countless hours in hot, greasy engine rooms. I’m going to cut through the jargon and give you the straight scoop on keeping your diesel happy. We’ll cover:

- Spotting trouble before it gets serious.

- What a real diagnostic process looks like.

- The maintenance you can’t afford to skip.

- The big decision: repair, rebuild, or replace?

- How to find a mechanic who won’t rip you off.

My goal is to give you the confidence to handle your engine, so let’s get into it.

Table of Contents

Your Diesel: The Toughest Engine on the Water

More Than Just a Motor

A marine diesel isn’t like the engine in your truck. It’s built for a different world. It’s designed to run for hundreds of hours at a time, push heavy loads, and fight off the corrosive salt air that eats everything else. The core of any good marine diesel engine repair philosophy is respecting that environment. You can’t just throw automotive parts at it and hope for the best.

Inside, you’ve got a few key systems working together: fuel, cooling, exhaust, and lubrication. When they’re all happy, your engine purrs. When one has a problem, the whole symphony falls apart. Proactive maintenance is what keeps them all in tune.

Listening to Your Engine: The Early Warning Signs

You’re the first line of defense. You know your boat’s sounds and smells better than anyone. Catching a problem early is the cheapest form of marine diesel engine repair there is.

What to Look and Listen For

- Performance Dips: Is it harder to start? Does it feel sluggish or fail to reach full RPMs? That’s not just a bad day; it’s a sign. Could be a clogged fuel filter, a tired turbo, or something worse.

- Weird Noises: Diesels are loud, but you know your diesel’s sound. Any new knocking, grinding, or excessive vibration is a cry for help. I had a client at Coconut Grove who ignored a “little knock” for a week. That little knock turned into a $15,000 rebuild.

- Exhaust Smoke Signals: The color of your exhaust tells a story.

- Black Smoke: Too much fuel, not enough air. Often a dirty air filter or injector issue.

- Blue Smoke: It’s burning oil. Could be worn rings or valve seals.

- White Smoke: Usually means water or coolant is getting into the combustion chamber. This is a big one—shut it down and get it checked.

- Leaks and Alarms: Don’t ignore drips or your dashboard. An oil leak is obvious, but a small coolant leak can lead to a catastrophic overheat. If a warning light comes on, it’s not a suggestion. It’s an order.

Trust your gut. If something feels off, it probably is. A quick inspection is always cheaper than a tow back to the marina.

The Mechanic’s Toolbox: Diagnostics and Common Fixes

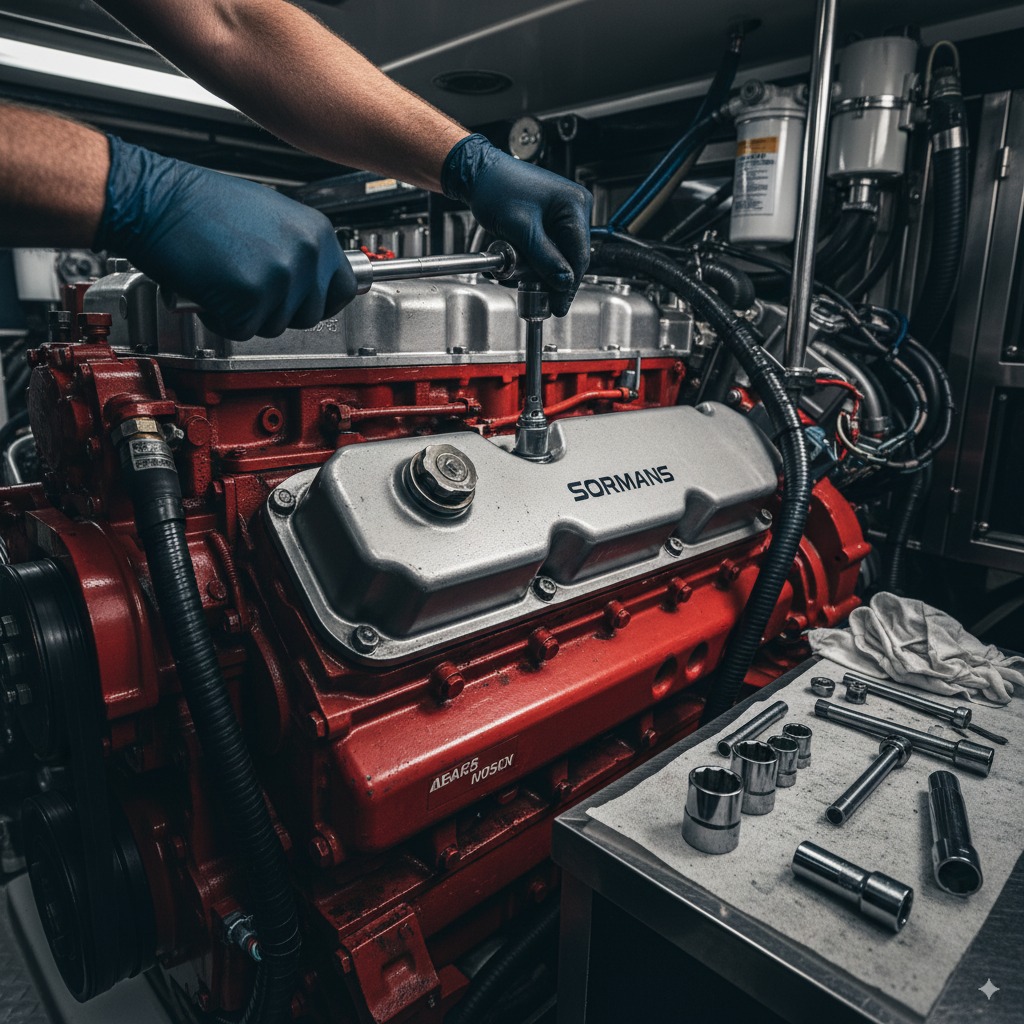

When a boat comes to my shop for marine diesel engine repair, I don’t start guessing. I start diagnosing. We use compression testers, fuel pressure gauges, and diagnostic software to find the root cause. It’s a methodical process.

What a Real Repair Looks Like

Once we know the problem, the fix usually falls into one of these categories. People always ask what a fix costs, so I put this table together from jobs I’ve seen around Miami. It’s not a perfect quote, but it gives you a ballpark idea.

| Common Marine Diesel Repair Job | Average Cost (Miami Area) | My Real-World Take on It |

|---|---|---|

| Fuel Injector Service/Replacement | $800 – $3,000+ | Pricey, but bad injectors kill performance and fuel economy. Don’t put it off. |

| Heat Exchanger & Cooling System Service | $500 – $2,500 | This is your engine’s #1 lifesaver. Overheating is a diesel killer. |

| Turbocharger Repair/Replacement | $2,000 – $7,000+ | A huge power booster, but a big-ticket item when it fails. |

| Starter or Alternator Replacement | $400 – $1,500 | Relatively simple, but you’re dead in the water without them. |

| Full Engine Rebuild (In-frame) | $10,000 – $30,000+ | Gives your engine a second life. A massive job, but cheaper than a new engine. |

A quick note on parts: always, always use high-quality OEM or equivalent parts. I’ve seen cheap aftermarket starters fail in six months. Saving a few bucks on a critical component is the most expensive mistake you can make in marine diesel engine repair.

Stay Out of My Shop: A Simple Maintenance Plan

The best marine diesel engine repair is the one you never have to do. A little proactive care goes a long, long way. My checklist is simple:

- Check Your Fluids: Before every trip, check the oil and coolant. It takes 30 seconds.

- Look for Leaks: A quick scan with a flashlight can spot a problem before it leaves the dock.

- Change Your Oil and Filters Religiously: Follow the manufacturer’s schedule (usually every 100-200 hours). Clean oil and clean fuel are everything.

- Inspect Your Impeller: The little rubber impeller in your raw water pump is the most important part of your cooling system. Check it every season and replace it yearly, whether it needs it or not. It’s a $50 part that can save you from a $20,000 engine.

You can do most of this yourself. But for the big stuff—valve adjustments, injector timing, etc.—know when to call a pro.

The Big Question: Repair, Rebuild, or Replace?

Sooner or later, every owner faces this. Here’s how I break it down for my clients:

- Repair: If it’s a single component failure (like an alternator or a water pump) on an otherwise healthy engine, a simple repair is the way to go.

- Rebuild: If you have major internal wear (like low compression) but the engine block is solid, a rebuild can be a great option. It restores the engine to factory specs for a fraction of the cost of a new one. This is a core part of the marine diesel engine repair world.

- Replace: If the block is cracked, parts are impossible to find, or you just want modern tech and a new warranty, it might be time for a full replacement. It’s the most expensive option, but sometimes it’s the smartest long-term move.

There’s no easy answer. It’s a balance of cost, the age of your engine, and how you plan to use your boat.

FAQ: Quick Questions I Get at the Dock

Is marine diesel engine repair really that much more expensive than car repair?

Yes, and for good reason. The parts are built tougher to handle the marine environment, production volumes are lower, and access is often a nightmare. You’re paying for durability and specialized labor.

Can I just use automotive parts on my marine diesel?

Please don’t. A car alternator isn’t sealed and can create a spark in your engine room—that’s a fire hazard. The metals aren’t designed for salt. It’s a dangerous and costly shortcut.

How do I find a good mechanic?

Word of mouth is king. Ask around at your marina. Look for someone who specializes in your brand of engine. A good reputation is earned, not bought.

What’s the single biggest mistake owners make?

Ignoring the small stuff. That little drip, that weird noise. They always turn into big, expensive problems. Your engine talks to you; you just have to listen.

How long should a marine diesel engine last?

With proper care? A long, long time. I’ve seen well-maintained diesels with 10,000+ hours still running strong. It all comes down to maintenance. That’s the secret to avoiding frequent marine diesel engine repair bills.

So, What’s the Bottom Line?

Look, your diesel engine is your ticket to freedom and your lifeline back to shore. Treating it with respect isn’t optional. If you take away anything from this, let it be these points.

- Be Your Engine’s First Responder: Pay attention. Your eyes and ears are the best diagnostic tools you have. Catching something early saves money, time, and stress.

- Maintenance Isn’t an Expense, It’s an Investment: A few hundred dollars a year in oil, filters, and impellers can save you tens of thousands in major marine diesel engine repair down the road.

- When in Doubt, Call a Pro: Don’t be a hero. Know your limits. For complex jobs, a certified mechanic with the right tools is your best friend.

- Don’t Cheap Out on Parts: Use quality OEM or equivalent parts. The marine environment is unforgiving, and a failed part can leave you stranded.

- Repair, Rebuild, or Replace? Think Long-Term: Don’t just look at the initial bill. Consider the long-term value, reliability, and peace of mind your decision will bring.

Your commitment to proper marine diesel engine repair and maintenance is what separates a great day on the water from a very, very bad one.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified in diesel engines. I’ve rebuilt everything from small Yanmars to massive CATs and Cummins engines at marinas like Bahia Mar and Dinner Key. If it runs on diesel and floats, I’ve probably had my hands on it.

Leave a Reply