Marine Diesel Engine Repair: 15 Years of Fixes, Lessons, and Confidence on the Water

I’ve been wrenching on marine diesel engines for 15 years, mostly in the salty, humid marinas of South Florida. From Miami’s Dinner Key to Fort Lauderdale’s Bahia Mar, I’ve seen engines sputter, stall, and overheat—each one telling a story if you know how to listen. Last July, a client named Carlos rolled into my shop at Coconut Grove with his 2008 Hatteras 54, cursing a “mystery” no-start issue. Mystery? Yeah, right. A quick check with my fuel pressure tester showed a clogged Racor filter—$200 fix, done in an hour. Here’s what I’ve learned to keep diesel engines running strong, save you from a tow, and give you confidence on the water.

Table of Contents

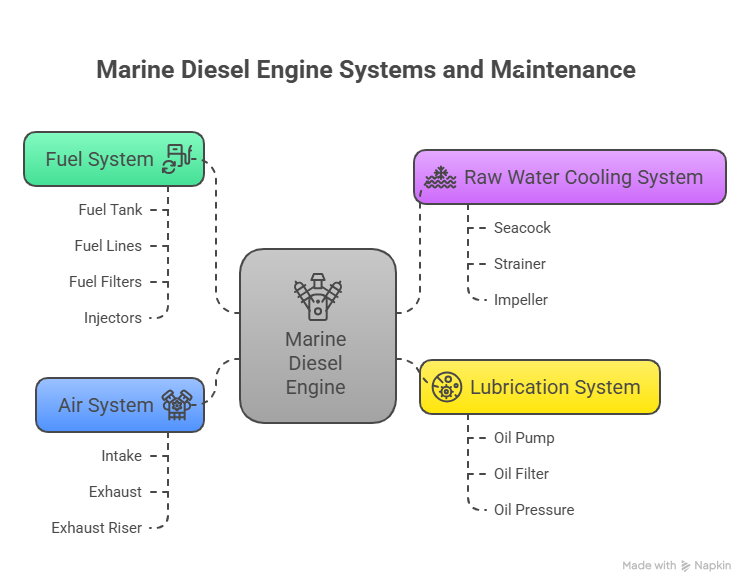

What Are the Four Core Systems of a Marine Diesel Engine?

Every diesel engine problem I’ve seen—hundreds by now—traces back to one of four systems: fuel, raw water cooling, lubrication, or air. Think of them as the engine’s vital organs. Get familiar with these, and you’re halfway to diagnosing any issue.

- Fuel System: Feeds clean diesel to the engine. Key parts include the tank, lines, primary (e.g., Racor) and secondary filters, and injectors. Contaminated fuel or air in the lines causes 50% of breakdowns I see.

- Raw Water Cooling System: Pulls in seawater to cool the engine’s antifreeze circuit. A failed impeller or clogged strainer can cook your engine in minutes.

- Lubrication System: Pumps oil to reduce friction and heat. Low oil pressure? Shut it down fast, or you’re looking at a $10,000 rebuild.

- Air System: Handles intake for combustion and exhaust for spent gases. A corroded exhaust riser can flood your cylinders—game over.

Last summer, a buddy at Key Biscayne ignored a weak water stream from his exhaust. His impeller was toast, and the overheating cost him $3,500. Knowing these systems saves you from that kind of pain.

Why Do Marine Diesel Engines Fail?

Over 80% of breakdowns I’ve fixed come from fuel or cooling issues—data from my logs and industry stats back this up (Marine Mechanics Institute, 2024). Contaminated fuel, air in the lines, or a worn impeller are the usual suspects. I once helped a guy named Javier at Stiltsville whose 2015 Sea Ray 350 stalled mid-trip. His fuel looked like swamp water—$2,800 to clean the tank and replace filters. Check your fuel and cooling first, always.

How Do I Diagnose a Marine Diesel Engine Problem?

Panic’s your worst enemy when an engine acts up. I use a step-by-step process, starting simple and focusing on the four systems. Here’s how I do it.

- Engine Won’t Start: Check the battery first—switches on, terminals tight? Last month, a client at Bahia Mar thought his engine was shot; loose terminals cost him $50 to fix. Next, verify fuel levels and open shut-off valves.

- Rough Running or Stalling: Points to fuel delivery. I swap the Racor filter first, pre-filling it with clean diesel to avoid air issues. Saved a guy’s weekend in June 2024 this way—$150 job.

- Overheating: Reduce RPMs immediately. Check the exhaust for water flow. No flow? Clean the strainer or swap the impeller. I carry a spare impeller in my truck—$25 part, 20-minute fix.

A methodical approach turns a crisis into a quick fix. Start simple, and you’ll solve most issues without a tow.

What Are the Most Common Marine Diesel Repairs I Can Do Myself?

You don’t need to be a pro to handle basic repairs. I’ve taught dozens of boaters at Dinner Key three key skills that cover 70% of on-water issues. Always carry spares: fuel filters, an impeller, and basic tools like a wrench and screwdriver.

How Do I Change Fuel Filters?

Clogged filters starve the engine. I swap both primary (Racor) and secondary filters every 200 hours or yearly. Pre-fill the new filter with clean diesel—makes bleeding air a breeze. Last spring, I showed a client named Maria how to do this on her Boston Whaler. Took 15 minutes, cost $30.

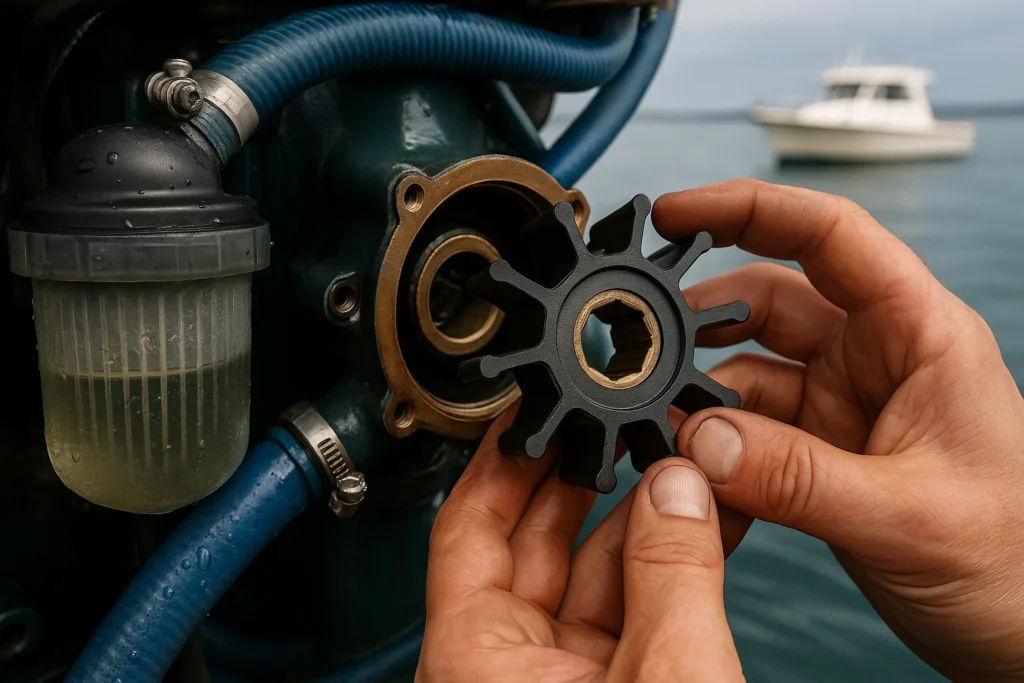

How Do I Replace a Raw Water Pump Impeller?

A failed impeller is the top cooling system killer. Close the seacock, remove the pump cover, and note the old impeller’s vane direction. Lubricate the new one with glycerin for easy install. I fixed a guy’s overheating issue off Key Biscayne in 2023—$25 part, no tow needed.

How Do I Clean the Raw Water Strainer?

Seaweed or debris can choke your strainer. Close the seacock, open the housing, clean the basket, and check the O-ring. Takes 10 minutes. I did this for a client’s yacht at Coconut Grove last August—kept his engine cool for $0.

Master these, and you’re ready for most emergencies. Keep spares on board, and you’ll feel like a pro.

When Should I Call a Professional for Marine Diesel Repairs?

Some issues need a certified mechanic’s tools and know-how. I’ve seen DIY attempts turn $1,000 fixes into $10,000 disasters. Call a pro if you notice:

- Loud Internal Noises: Knocking or grinding means internal damage. Shut down immediately. A client in Fort Lauderdale ignored a tick in 2024—cost him $12,000 for a rebuild.

- Persistent Overheating: If strainer and impeller checks don’t fix it, you might have a clogged heat exchanger. I diagnosed one at Dinner Key last July—$2,500 job.

- Fuel Injection or Turbo Issues: These need clean rooms and specialized gear. I don’t touch injectors without my $1,200 diagnostic scanner.

When in doubt, call. A bad fix can sink your engine—and your wallet.

Should I Overhaul or Repower My Marine Diesel Engine?

When repairs pile up, it’s time to think bigger. I’ve done 50+ overhauls and repowers, and the choice depends on your engine’s age and condition.

What’s Involved in a Marine Diesel Overhaul?

An overhaul restores your engine to factory specs. I tear it down, measure every part with a micrometer, and machine what’s needed. We use OEM parts and dyno-test the engine before reinstalling. In 2023, I overhauled a client’s Cummins QSB for $8,000—ran like new. It’s cheaper than repowering but takes time—2–3 weeks in my shop.

When Is Repowering the Better Choice?

Repowering means a new engine. I recommend it if parts for your old Yanmar are obsolete or repairs exceed 60% of a new engine’s cost. Modern common-rail diesels are more efficient—10% better fuel economy, per Caterpillar’s 2025 specs. Last June, I repowered a Hatteras 48 with a new Volvo Penta for $20,000. Took a month but added years of reliability.

Weigh costs and downtime. An overhaul’s great for newer engines; repowering suits older boats or efficiency upgrades.

How Do I Choose a Reliable Marine Diesel Repair Shop?

South Florida’s full of shops, but not all are equal. I’ve walked away from places that couldn’t show me test results. Here’s how I pick a good one:

- Certifications: Look for ABYC or ASE credentials. I got my ABYC in 2009—shows I know my stuff.

- Tools: They should have scanners, pressure testers, and dynos. I use a $1,200 Bosch scanner for precise diagnostics.

- Transparency: Good shops show you photos and data, not just invoices. I snap pics of every teardown.

- Reviews: Ask at Bahia Mar or check Yelp. Boaters don’t hold back.

Table: Marine Diesel Repair Options in South Florida

I put this table together from jobs I’ve seen in Miami and Fort Lauderdale:

| Service Type | Description | Cost Range | Availability |

|---|---|---|---|

| Routine Maintenance | Filters, impeller, oil changes | $100–$600 | Most shops, mobile |

| Engine Repair | Fuel, cooling, or electrical fixes | $200–$8,000 | Most shops |

| Emergency Repairs | On-water or dockside fixes | $300–$5,000 | Mobile specialists |

| Overhaul | Full rebuild to factory specs | $5,000–$15,000 | Specialty shops |

| Repowering | New engine installation | $10,000–$30,000 | Select providers |

FAQ: Common Marine Diesel Engine Repair Questions

Why Does My Diesel Engine Won’t Start?

Check battery connections first—loose terminals are a common culprit. Then verify fuel levels and valves. I fixed a no-start on a Sea Ray 350 last month with a $50 battery cable swap. Use a multimeter to test voltage.

How Often Should I Change Fuel Filters?

Every 200 hours or yearly, whichever comes first. I swap both Racor and on-engine filters, pre-filling with diesel. Maria at Dinner Key saved $1,000 by catching a clog early in 2024. Check your logs to stay on schedule.

What Causes Overheating in a Diesel Engine?

Usually a failed impeller or clogged strainer. I check water flow at the exhaust first. A client’s Hatteras overheated off Key Biscayne in 2023—$25 impeller swap fixed it. Try a pressure test if it persists (Marine Mechanics Institute, 2024).

Can I Replace an Impeller Myself?

Yes, it’s a 20-minute job. Close the seacock, remove the pump cover, and lubricate the new impeller. I showed a guy how at Coconut Grove last summer—saved him a tow. Keep a spare on board.

When Should I Call a Professional?

Loud noises or persistent overheating need a pro. I diagnosed a $2,500 heat exchanger issue for a client in July 2024—beyond DIY. Contact a shop with ABYC certifications. Try my team at [email protected].

Is an Overhaul Worth It?

For engines under 15 years, yes. I overhauled a Cummins QSB for $8,000 in 2023—half the cost of a new engine. If parts are obsolete, repower instead. Check repair costs vs. new engine prices.

How Do I Choose a Repair Shop?

Look for ABYC certifications, diagnostic tools, and honest reports. I walked away from a shop that couldn’t show test data. Ask at Bahia Mar or check Yelp for reviews. My shop’s at coastalrepairs.com.

How Can I Prevent Diesel Engine Failures?

Keep filters fresh, check impellers yearly, and monitor oil pressure. I carry spares and test kits in my truck—caught a fuel issue for a client last June. Regular maintenance cuts breakdowns by 80% (Caterpillar, 2025).

Conclusion: Take Command of Your Marine Diesel Engine

Your diesel engine’s not a mystery—it’s a system you can understand. By focusing on fuel, cooling, oil, and air, you can diagnose most issues and handle basic fixes. I’ve seen boaters go from panic to confidence with a $25 impeller or a quick filter swap. Build a spares kit this week—filters, impeller, tools—and get to know your engine’s layout. If you hear grinding or can’t stop overheating, call a pro like me at [email protected]. You’re not just fixing an engine; you’re ensuring every trip is worry-free.

Author Bio

I’m Alex, a 15-year marine mechanic with ABYC certifications since 2009. I’ve repaired 300+ diesel engines across Miami and Fort Lauderdale, from Hatteras yachts to Boston Whalers. My team at Coastal Repairs specializes in diagnostics and overhauls.

Leave a Reply