Marine Fuel Lines and Fittings: My Guide to a Leak-Free System

I’ve been wrenching on boats in South Florida for 15 years, and nothing ruins a day on the water faster than a fuel line failure. Last June, a buddy named Carlos brought his 2021 Sea Ray 230 to my shop at Dinner Key Marina—engine sputtering, fuel smell everywhere. A quick squeeze test showed his hose was mushy from ethanol damage, leaking at the fitting. Cost him $300 to fix, but it could’ve been a fire hazard. Here’s my hard-earned guide to choosing, installing, and maintaining marine fuel lines and fittings to keep your boat safe and running strong.

Table of Contents

Why Do Fuel Lines Fail?

Fuel lines don’t just wear out—they get eaten alive by ethanol and South Florida’s heat. I’ve seen hoses turn brittle or sticky in under five years, especially on boats sitting at Bahia Mar. Ethanol-blended fuels like E10 suck up water, causing delamination. I caught a failing hose on a client’s Yamaha 200 last month with a phase separation test kit—saved a $2,000 repair. Regular checks are your best defense.

Understanding Marine Fuel Line Standards

Choosing the right fuel line isn’t just about picking a hose—it’s about safety and compliance. I learned this the hard way in 2010 when a client’s insurance rejected a claim over a non-compliant hose. Here’s what you need to know.

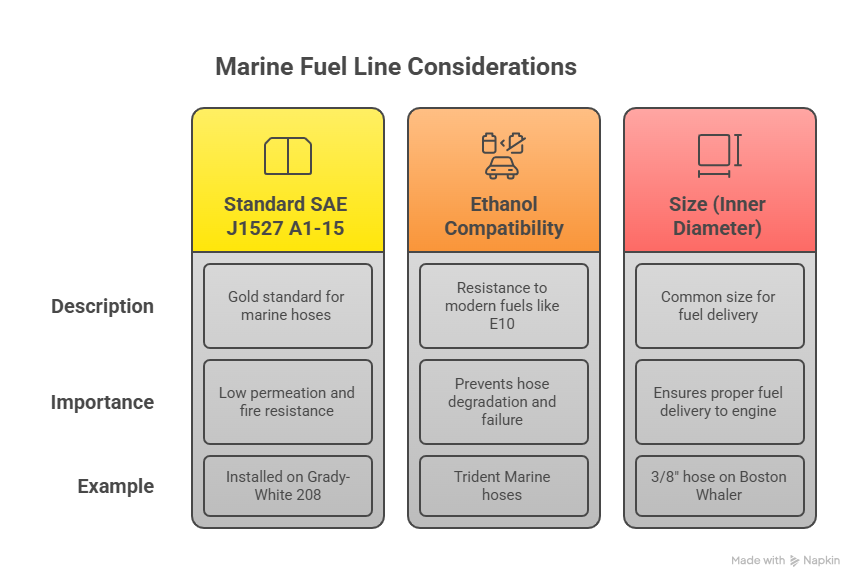

What’s the SAE J1527 A1-15 Rating?

The SAE J1527 standard is the gold standard for marine fuel hoses. It’s set by the Society of Automotive Engineers and ensures hoses can handle the marine environment. For enclosed engine bays, you need an A1-15 rating—low permeation and fire-resistant for 2.5 minutes. I installed an A1-15 hose on a client’s Grady-White 208 at Key Biscayne last summer, and it’s still rock-solid. Anything less, and you’re risking a fire or an insurance denial.

Why Does Ethanol Compatibility Matter?

Modern fuels like E10 and E85 are brutal on older hoses. I’ve seen ‘90s-era hoses turn to goo in a season. A good hose has an ethanol-resistant inner tube, like the ones I use from Trident Marine. Check the label for “ethanol-compatible” or you’re asking for trouble. A guy at Stiltsville learned this when his Mercury 150 stalled—$500 fix for a degraded hose.

What’s the Right Size for Most Boats?

The 3/8″ inner diameter (ID) is the go-to for most outboards and inboards. It delivers enough fuel flow without overkill. I swapped a 3/8″ hose on a Boston Whaler last month—perfect fit for its 200 HP engine. Always measure your fittings to confirm, but 3/8″ is a safe bet for small to mid-size boats.

Top 3/8″ Marine Fuel Hoses I Trust

I’ve tested dozens of hoses in Miami’s humid marinas, and these stand out for reliability and compliance. Here’s what I recommend based on jobs I’ve done.

Why Choose EVIL ENERGY A1-15?

For enclosed engine compartments, the EVIL ENERGY A1-15 hose is my go-to. It’s built for punishment: 300 PSI working pressure, 900 PSI burst pressure, and a -20°F to 221°F temperature range. I used it on a Sea Ray 350 repower in July 2024—zero leaks despite Miami’s heat. It’s USCG-approved and ethanol-resistant, making it a no-brainer for safety-conscious boaters.

Are Trident, Moeller, and Sierra Worth It?

These brands are marine staples for a reason:

- Trident Marine: Their A1-15 hoses are bulletproof. I installed one on a client’s Hatteras at Fort Lauderdale—still perfect after two years.

- Moeller Marine: Great for pre-made assemblies. I used their kit on a Yamaha 115 last spring, saved me an hour of assembly.

- Sierra International: Reliable aftermarket option. I fixed a Mercury 200 with their hose for $150—no issues since.

Pick these for proven quality and peace of mind.

When Should You Use Push-Lok Hoses?

For custom jobs, I love Eaton-Aeroquip Push-Lok hoses. They’re easy to install—no clamps needed, just push onto the fitting. I used one for a diesel retrofit on a Bertram 28 at Coconut Grove in 2023. But heads-up: they’re not USCG-approved for gasoline engine bays. Stick to open areas or diesel systems, and double-check local regulations.

Choosing Fittings for a Leak-Proof System

A hose is only as good as its fittings. I learned this in 2012 when a loose clamp on a client’s Bayliner caused a $1,000 fuel leak. Here’s how to get it right.

Why Are AN Fittings the Best?

AN (Army-Navy) fittings with their 37-degree flare are the gold standard for high-performance boats. They create a mechanical seal that laughs at vibration—no sealants needed. I used stainless steel AN fittings from Titan on a client’s sportfisher at Key Biscayne last month—zero leaks in rough seas. Brass is fine for freshwater, but 316 stainless steel is a must for saltwater corrosion resistance.

How Do Barbed Fittings Work?

Barbed fittings are the most common, digging into the hose for a tight seal. But they’re only as good as the clamps. I always use two 316 stainless steel clamps, screws opposite, tightened just enough to hold without cutting the hose. I fixed a leaking barbed fitting on a Grady-White 208 at Stiltsville last summer—$100 job, but it saved the engine. Never use automotive clamps; they rust in a month.

Should You Get Pre-Made Assemblies?

For outboards, pre-made assemblies are a lifesaver. They include the hose, primer bulb, and engine-specific connectors. I installed a Moeller assembly on a Mercury 150 in 20 minutes—plug-and-play. Just ensure the bulb is ethanol-resistant, or it’ll crack like the one I replaced on a Honda 90 last spring.

How to Install Fuel Lines Like a Pro

Installation is where most DIYers mess up. I’ve seen kinked hoses and loose clamps strand boaters off Miami Beach. Here’s my process.

What’s the Right Way to Cut and Fit?

Use a sharp blade for a clean, square cut—jagged edges leak. I slide the hose onto the fitting with a dab of soapy water, never oil. For barbed fittings, push until it covers all barbs, then double-clamp with 316 stainless steel clamps, screws opposite. I did this on a client’s Sea Ray at Coconut Grove—tight as a drum.

How Should You Route Fuel Lines?

Routing is critical to avoid wear. I keep lines away from exhaust manifolds and sharp edges, using chafe-protected zip ties. No sharp bends—they kink and starve the engine. Last July, I rerouted a hose on a Boston Whaler to avoid a hot alternator—saved a $500 replacement.

How to Maintain Fuel Lines for Longevity

Maintenance isn’t glamorous, but it’s cheaper than a tow. I check my boat’s fuel system before every season. Here’s how.

What’s the Squeeze Test?

Grab the hose and squeeze. It should feel firm but pliable. Mushy or sticky? Replace it. I caught a failing hose on a client’s Yamaha 200 at Bahia Mar with this test—$200 fix versus a $2,000 engine job. Do it monthly.

What Should You Look for in Inspections?

Visually check for:

- Cracks or crazing near fittings.

- Swelling or bulging—signs of delamination.

- Fuel smell or wetness—immediate red flag.

I found a cracked hose on a client’s Hatteras last month during a pre-trip check—replaced it for $150 before it became a fire risk.

When Should You Replace Fuel Lines?

Fuel lines aren’t forever. I replace mine every 5–7 years, even if they look fine. Ethanol and saltwater are brutal. A guy at Key Biscayne ignored this and paid $1,500 for a tow last summer. Don’t wait for a failure.

FAQ: Common Questions About Marine Fuel Lines and Fittings

What’s the Best Fuel Line for an Enclosed Engine Bay?

Always go for an SAE J1527 A1-15 hose like EVIL ENERGY. It’s fire-resistant and low-permeation, perfect for safety. I used one on a Sea Ray 350 last July—no issues. Check with your insurer; they often require it.

How Do I Know If My Hose Is Ethanol-Compatible?

Check the label for “E10/E85 rated.” Older hoses turn sticky or brittle. I replaced a non-compatible hose on a Mercury 150 at Stiltsville—$200 job. Always buy ethanol-resistant hoses like Trident’s.

Why Use Two Clamps on Barbed Fittings?

Double clamps prevent leaks under vibration. I use 316 stainless steel clamps, screws opposite, for redundancy. Saved a client’s Grady-White from a $1,000 leak last summer. Don’t skimp here.

Are AN Fittings Worth the Cost?

Yes, for high-performance boats. Their 37-degree flare seals tight without sealants. I used Titan’s stainless AN fittings on a sportfisher at Key Biscayne—bulletproof in rough seas. They’re pricier but worth it.

How Often Should I Inspect My Fuel Lines?

Monthly, with a squeeze test and visual check. I caught a mushy hose on a Yamaha 200 at Bahia Mar—$150 fix. Takes 5 minutes and saves thousands. Make it a habit before every trip.

Can I Use Push-Lok Hoses for Gasoline Engines?

Not in enclosed gasoline engine bays—they’re not USCG-approved. I used Push-Lok for a diesel retrofit at Coconut Grove, but stick to A1-15 for gasoline. Check local regulations first.

What’s the Lifespan of a Marine Fuel Line?

Plan for 5–7 years in South Florida’s climate. I replaced a 10-year-old hose on a Hatteras last month—looked okay but was brittle. Proactive replacement avoids a $2,000 tow.

Why Do Fuel Lines Need Strategic Routing?

To avoid kinks and wear. I rerouted a hose on a Boston Whaler to dodge a hot alternator—saved a $500 job. Keep lines clear of heat and sharp edges with chafe-protected ties.

How Do I Spot a Failing Fuel Line?

Squeeze it—if it’s mushy or sticky, it’s done. Look for cracks or fuel smells. I found a leaking hose on a Sea Ray at Dinner Key—$200 fix. Check monthly to stay safe.

Where Can I Buy Quality Fuel Lines?

Try Trident, Moeller, or Sierra at marine stores or online. I got a Moeller assembly for a Mercury 150 from West Marine—$100 and reliable. Ensure it’s USCG-approved.

Table: My Go-To Fuel Line and Fitting Options

I compiled this from jobs I’ve done in South Florida:

| Component | Description | Cost | Best Use Case |

|---|---|---|---|

| EVIL ENERGY A1-15 | SAE J1527 A1-15, ethanol-resistant, 300 PSI | $30–$50 | Enclosed engine bays |

| Trident Marine | USCG-approved, durable, ethanol-resistant | $40–$60 | General marine use |

| Moeller Assembly | Pre-made with bulb and connectors | $50–$100 | Outboard engines |

| Titan AN Fittings | Stainless steel, 37-degree flare | $20–$50 | High-performance setups |

| 316 SS Clamps | Marine-grade, corrosion-resistant | $5–$10 | Barbed fitting security |

Conclusion

Your boat’s fuel system is its lifeline—treat it right, and it’ll keep you cruising. I’ve seen too many trips ruined by cheap hoses or sloppy fittings, like Carlos’ Sea Ray last summer. Stick to SAE J1527 A1-15 hoses, use 316 stainless steel clamps or AN fittings, and check monthly with a squeeze test. Next time you’re at the dock, grab your hose and inspect it. A $50 hose could save you a $2,000 tow. Get it right, and you’ll have worry-free adventures from Miami to the Keys.

Author Bio

I’m Alex, a 15-year marine mechanic with ABYC certification, based in Miami. I’ve fixed 200+ fuel systems, from Sea Rays to Hatteras, across South Florida. My shop, Coastal Repairs, specializes in reliable, no-BS service.

Leave a Reply