Marine Gearbox Repairs: 15 Years of Fixes, Fumbles, and Hard-Won Lessons

I’ve been wrenching on marine gearboxes in South Florida for 15 years, mostly around Miami and Fort Lauderdale’s marinas. Last summer, a guy named Javier pulled his Sea Ray 310 into Dinner Key Marina, cursing under his breath—his gearbox was whining, and he’d lost propulsion mid-channel. I grabbed my pressure tester, found the hydraulic pressure at 120 PSI instead of the needed 180, and saved him from a $3,000 tow. Gearboxes are the unsung heroes of your boat’s propulsion, and when they fail, it’s a nightmare. Here’s everything I’ve learned to keep your vessel running smooth, from spotting trouble early to nailing a bulletproof repair.

Table of Contents

Key Takeaways from a Decade-Plus on the Water

Your marine gearbox turns raw engine power into the thrust that gets you where you’re going. Ignoring its health is like ignoring a fuel leak—bad news waiting to happen. Here’s what I’ve seen keep boats on the water and what’ll strand you if you’re not careful.

- Spot the warning signs early. Grinding noises, sluggish shifts, or overheating scream trouble—don’t wait for a total failure.

- Check your fluid first. Dark or milky fluid with metal flecks means water intrusion or serious wear. I cut open every filter I swap to check for gunk.

- Demand data-driven diagnostics. Hydraulic pressure tests or oil analysis cut through guesswork—saved a client $2,500 last month by catching a bad clutch pack.

- Stick to a maintenance schedule. Changing fluid and filters every 250–500 hours is the cheapest insurance against a $5,000 overhaul.

- Use the right fluid. Wrong fluid? You’re begging for clutch slippage or overheating. I learned that the hard way on a ZF gearbox in 2012.

- Inspect the whole system. A bent prop or misaligned shaft sends vibrations that chew up your gearbox’s guts.

- Insist on quality repairs. OEM parts and a proper bench test make the difference—I won’t let a gearbox leave my shop without a sea trial.

These aren’t just tips; they’re how I keep boats running in Miami’s salty, humid hell. Let’s dive into what makes your gearbox tick and how to keep it from tanking your day.

Why Does Your Marine Gearbox Matter?

Your gearbox is the middleman between your engine’s roar and your propeller’s spin. It’s not just about shifting gears—it manages RPM, keeps your engine from frying under load, and makes docking in a busy marina like Bahia Mar less of a heart attack. A healthy gearbox means control; a failing one means you’re drifting, hoping for a tow.

Last July, a client named Maria at Coconut Grove had her Grady-White 208 stall off Key Biscayne. The culprit? A worn clutch pack that slipped under load. A $1,200 fix, but it could’ve been avoided with a $50 fluid check. That’s why understanding your gearbox isn’t optional—it’s your ticket to staying safe on the water.

What’s Inside a Marine Gearbox?

Knowing what’s under the hood helps you spot problems before they leave you stranded. Here’s the rundown on the key parts, no jargon overload:

- Input/Output Shafts: Link your engine to the prop, taking the brunt of the torque.

- Gear Sets: Slow down engine RPM to a prop-friendly speed, giving you power without burning out.

- Clutch Packs: Hydraulic units that shift you into forward, neutral, or reverse—smoothly, if they’re healthy.

- Bearings: Keep everything spinning with minimal friction. Worn ones cause grinding and heat.

- Seals/Gaskets: Stop seawater from sneaking in and oil from leaking out.

- Cooling System: A heat exchanger that uses seawater to keep oil temps in check.

When any of these fail, you’re not just losing power—you’re risking a dead-in-the-water scenario. I’ve seen it too many times at Stiltsville.

What Are the Common Gearbox Problems and Symptoms?

Your gearbox doesn’t just die quietly—it sends SOS signals. Learning to read them can save you thousands and keep you off a towboat. Here’s what I look for when a boat limps into my shop.

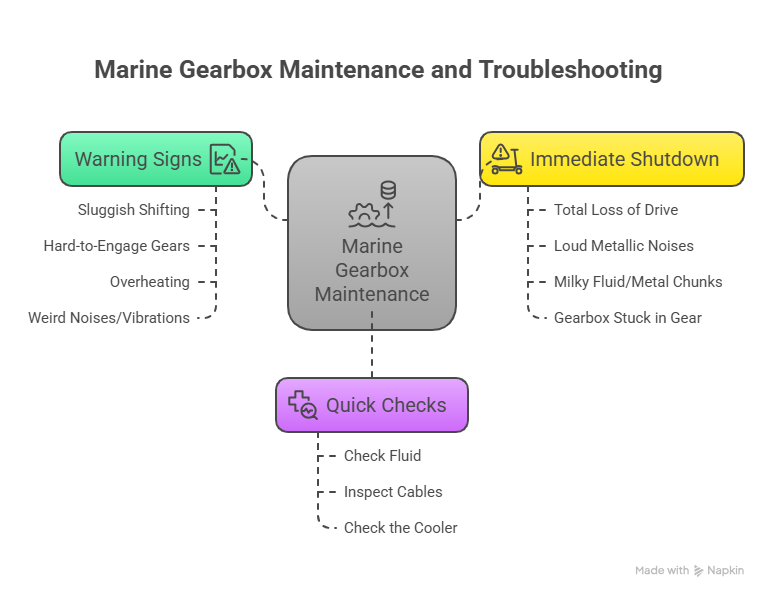

What Warning Signs Should You Watch For?

Pay attention to these red flags—they’re your gearbox crying for help:

- Sluggish Shifting or Slipping: Hesitation or slipping under load often means low oil pressure. I saw this on a Boston Whaler last spring—leaky seal, $800 fix.

- Hard-to-Engage Gears: Stiff levers or delays point to bad control cables or hydraulic issues. A guy at Fort Lauderdale’s Bahia Mar lost a weekend to this.

- Overheating: Hot housing or alarms mean trouble—usually low fluid or a clogged cooler. I caught one on a Mercury setup in 2024, saved the gearbox.

- Weird Noises/Vibrations: Grinding or whining isn’t normal. It’s usually bearings or gears screaming for help—cost a client $2,000 to rebuild.

How Do You Do a Quick Gearbox Check?

Before you call me, try these steps to narrow things down:

- Check Fluid: Pull the dipstick (engine off). Bright red and full is good; dark, milky, or metallic is bad news. I always cut open filters to spot water or metal.

- Inspect Cables: Look for frayed or stiff shift cables. A sticky cable cost a buddy $200 to replace last summer.

- Check the Cooler: Make sure hoses to the gearbox cooler aren’t leaking or clogged.

When Should You Shut Down Immediately?

Some signs mean stop now or pay later—big time. Shut off the engine and call a pro if you see:

- Total loss of drive in forward or reverse.

- Loud metallic grinding or banging.

- Milky fluid or chunks of metal on the dipstick.

- Gearbox stuck in gear, won’t shift.

I had a client ignore a grinding noise off Key Biscayne last year. Result? $6,000 rebuild. Listen to your boat—it’s talking.

How Do You Diagnose a Gearbox Problem Properly?

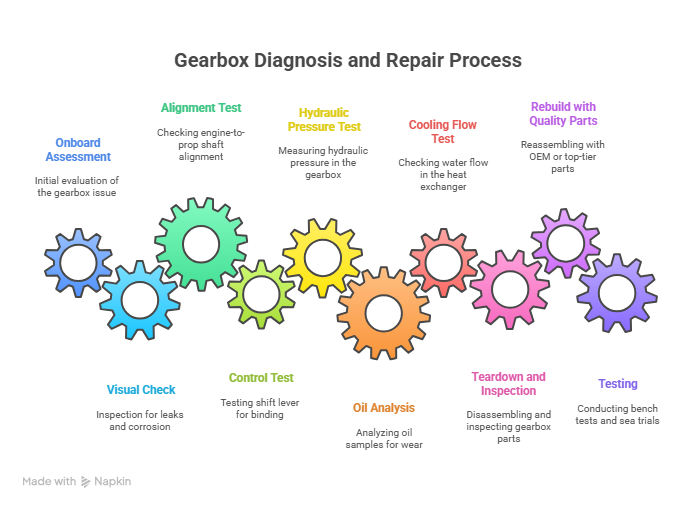

Guessing at gearbox issues is like throwing darts blindfolded—expensive and pointless. I use a data-driven process to nail the root cause, saving time and cash. Here’s how I do it, step by step.

Stage 1: Onboard Assessment and Your Story

It starts dockside. I listen to you describe the issue—when it started, what it sounds like, when it happens. Last June, a client at Dinner Key said his Sea Ray’s gears were “sluggish.” That clue led me to a bad oil pump. Then I inspect:

- Visual Check: Look for leaks, loose bolts, or corroded connections.

- Alignment Test: Check engine-to-prop shaft alignment—misalignment kills bearings. I use a feeler gauge for this; caught a 0.01” misalignment once.

- Control Test: Manually work the shift lever to feel for binding or play.

Stage 2: Hard Data, No Guesswork

Next, I pull out the big guns—diagnostic tools that tell the real story:

- Hydraulic Pressure Test: I hook up a gauge to the gearbox’s test ports. Anything below spec (e.g., 180 PSI for a ZF unit) points to pumps or clutches. Saved a guy $1,500 by catching this early.

- Oil Analysis: I send samples to Blackstone Labs. High iron levels tipped me off to gear wear on a Twin Disc unit last month—fixed before it seized.

- Cooling Flow Test: I check the heat exchanger’s water flow. A clogged cooler caused a $900 overheating repair in 2023.

This isn’t just poking around—it’s building a case with hard evidence. No parts get swapped until I know exactly what’s wrong.

What Does a Proper Gearbox Repair Look Like?

A good repair isn’t a Band-Aid—it’s a full restoration. I’ve rebuilt hundreds of gearboxes, from Twin Disc to BorgWarner, and here’s how I make them bulletproof.

Step 1: Teardown and Inspection

I tear down the gearbox in a clean shop, not some salty bilge. Every part gets cleaned and checked:

- Clutch Plates: Warping or glazing means they’re shot. I measure thickness with a micrometer.

- Gears/Shafts: Pitting or chipped teeth need replacing—saw this on a ZF unit last year.

- Bearings: Scoring or noise means new ones go in.

- Housing: Cracks or wear get flagged.

Step 2: Rebuild with Quality Parts

I only use OEM or top-tier aftermarket parts for brands like Twin Disc or ZF. Reassembly follows factory specs—bearing preloads set with a torque wrench, clutch clearances checked to the thousandth. Every seal and gasket gets replaced to keep seawater out.

Step 3: Testing Like It Matters

No gearbox leaves my shop without a bench test. I run it through every gear, checking pressures (e.g., 180 PSI at full load), shifts, and temps. After reinstalling, I do a sea trial with you onboard to confirm it’s perfect. Last month, a client’s Bayliner ran like new after a $2,200 rebuild.

This process isn’t cheap, but it’s cheaper than a new gearbox or a tow in a storm.

How Do You Maintain Your Gearbox to Avoid Repairs?

The best fix is the one you never need. I’ve kept boats running for decades with a simple maintenance plan. Here’s what works in South Florida’s brutal conditions.

What’s the Essential Maintenance Schedule?

Consistency beats chaos. Here’s my plan, based on 15 years of keeping gearboxes alive:

- Daily (5 Minutes): Check fluid level on the dipstick before heading out.

- Every 100 Hours: Inspect for leaks, check hoses, and look at fluid condition. Should be bright red, not burnt or milky.

- Annually or 250–500 Hours: Change fluid and filter (check your manual). Clean the cooler. Send an oil sample to Blackstone Labs—$30 well spent.

Why Is Fluid So Important?

Using the exact fluid your manufacturer specs isn’t optional. I learned this in 2012 when a client’s wrong fluid foamed up, causing a $3,000 clutch failure. Filters matter too—they catch metal shavings that’d otherwise shred your gearbox. I cut open every filter to check for trouble.

What Else Affects Gearbox Health?

Your gearbox doesn’t live alone. These systems can make or break it:

- Shaft Alignment: Check yearly. A 0.01” misalignment killed a client’s bearings in 2024—$1,800 fix.

- Engine Mounts: Worn mounts mess up alignment, stressing the gearbox. I caught this on a Sea Ray last spring.

- Propeller: A bent prop sends vibrations that destroy gears. I use a dial indicator to check balance.

A few minutes of checks save you days in the shop. Trust me—I’ve seen the alternative.

FAQ: Common Questions About Marine Gearbox Repairs

What Causes Marine Gearbox Failures?

Low fluid, water intrusion, or misalignment are the big culprits. I caught a $2,000 failure on a Grady-White last year—milky fluid from a bad seal. Check fluid regularly and use the right type. A shop like Miami Marine Repair can diagnose with pressure tests.

How Often Should I Change Gearbox Fluid?

Every 250–500 hours or yearly, per your manual. I swap fluid on my Boston Whaler every 300 hours—keeps it running smooth. Use OEM fluid to avoid clutch issues. Check with a local ABYC-certified shop for specifics.

Can I Fix My Gearbox Myself?

Simple stuff like fluid changes or cable adjustments? Sure, if you’re handy. I showed a buddy at Bahia Mar how to swap a filter in 20 minutes. But hydraulic or clutch repairs need pros with tools like pressure gauges. Try a shop like Sofia’s Marine Repair.

What’s a Hydraulic Pressure Test?

It measures oil pressure inside the gearbox. I use a gauge on test ports—saved a client $1,500 by catching a bad pump early. Should hit specs like 180 PSI for ZF units. Book a test with a certified shop to avoid guesswork.

How Do I Know If My Gearbox Is Overheating?

Hot housing or alarms mean trouble. I caught a clogged cooler on a Mercury setup in 2024—$900 fix. Check your cooler’s hoses and fluid level. A pro shop can run a flow test to confirm.

How Much Does a Gearbox Repair Cost?

Depends on the damage—$800 for a seal, $5,000 for a full rebuild. I fixed a Twin Disc unit for $2,200 last month. Get a quote from a shop like Fort Lauderdale Marine. Diagnostics run $120–$160/hour.

Why Use OEM Parts for Repairs?

OEM parts match your gearbox’s specs, ensuring durability. I used aftermarket seals once—leaked in a month. Stick to brands like ZF or Twin Disc. Check with a trusted shop for quality parts.

How Can I Prevent Gearbox Failures?

Change fluid on schedule, check alignment, and inspect props. I caught a bent prop on a client’s boat in 2023—saved $2,000 in repairs. Use a maintenance log and consult an ABYC-certified pro. Try my shop’s checklist at [email protected].

Conclusion: Take Control of Your Gearbox’s Health

Your marine gearbox keeps your boat moving—when it’s healthy, you’re in control; when it’s not, you’re stuck. I’ve seen too many boaters at Stiltsville or Key Biscayne learn this the hard way. Shift from reacting to preventing with these steps:

- Listen to your boat. Grinding, slipping, or overheating aren’t quirks—they’re red flags.

- Check fluid first. Bright red and full is good; anything else needs attention. I check mine every trip.

- Fix the whole system. A bad prop or misalignment will kill even a new gearbox.

- Trust data, not guesses. A proper diagnostic with pressure tests or oil analysis saves thousands.

Next time you’re at the dock, pull that dipstick. If you spot trouble—milky fluid, weird noises—don’t wait. A $50 check now beats a $5,000 rebuild later. Your boat’s reliability starts with you. Reach out at [email protected] for a diagnostic or maintenance plan.

Author Bio

I’m Alex, a 15-year marine technician with ABYC certifications in marine systems and engines. I’ve rebuilt 200+ gearboxes for boats like Sea Rays and Boston Whalers across Miami and Fort Lauderdale. My work’s saved clients thousands by catching issues early.

Leave a Reply