Rebuilding an Evinrude Carburetor: 15 Years of Fixes, Fumbles, and Lessons Learned

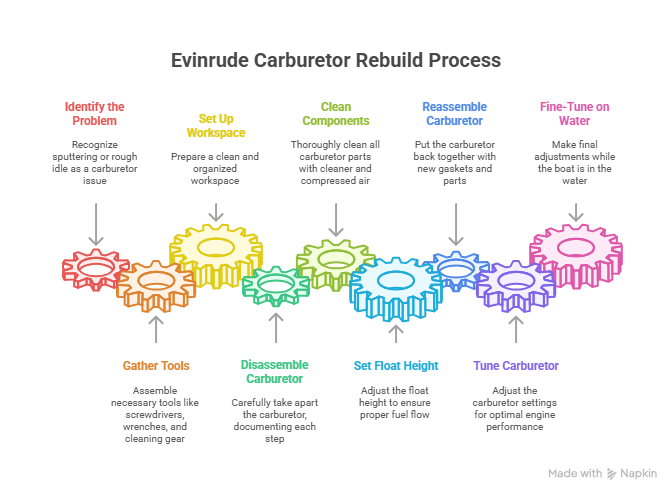

I’ve been wrenching on outboard engines in South Florida for 15 years, mostly at marinas like Dinner Key and Bahia Mar. Back in 2009, I started rebuilding Evinrude carburetors with my dad in our Fort Lauderdale garage, and I’ve probably torn down 200 of them since. Last July, a buddy named Javier at Coconut Grove brought me his 1998 Evinrude 115—sputtering like it was possessed. Took me 20 minutes with a fuel pressure tester to spot a clogged jet, saving him a $600 shop bill. Here’s my no-nonsense guide to rebuilding your Evinrude carburetor, packed with what I’ve learned to keep your engine humming all season.

Why Does My Evinrude Sputter or Idle Rough?

That annoying sputter or rough idle usually points to a dirty carburetor. Saltwater, ethanol fuel, and time clog jets and gum up passages, starving your engine of fuel. I’ve seen this kill performance on everything from 90 HP to 250 HP Evinrudes. A rebuild fixes over 90% of fuel-related issues—cheaper than a $1,000 shop visit. Here’s how I tackle it, step by step, to get your boat back on the water.

What Tools Do I Need for an Evinrude Carburetor Rebuild?

Before you touch a screw, set up right—it saves headaches. Last summer, I helped a client at Key Biscayne rebuild his Evinrude 150’s carb. He didn’t have a proper screwdriver, stripped a jet, and turned a $200 job into a $400 one. Here’s what I keep in my toolbox:

- Screwdrivers and Wrenches: A flathead that perfectly fits the main jet (test it first—brass strips easy) and a 1/2″ or 9/16″ wrench for mounting nuts.

- Cleaning Gear: Carburetor cleaner (I use CRC), compressed air (80–100 PSI), and a soft wire (like a strand from 12-gauge electrical wire) for jets.

- Extras: Partitioned tray for tiny parts, a phone for photos, and a service manual for your engine’s specs.

Find your engine’s model and serial number on the transom bracket. Order the exact rebuild kit—generic kits are a recipe for leaks. My go-to is Sierra Marine; their kits cost $30–$50 and cover most Evinrude models.

How Do I Set Up a Workspace for a Carburetor Rebuild?

A clean workspace is your best friend. I learned this the hard way in 2012 when I lost a float needle on a cluttered bench—spent an hour searching. Here’s my setup:

- Bright, Clean Area: Work under good lighting to spot tiny passages. A garage bench or kitchen table (if you’re brave) works.

- Organize Parts: Use a muffin tin or small cups to keep screws and jets from vanishing.

- Safety First: Disconnect the battery to avoid accidental starts. Use carb cleaner in a well-ventilated spot—it’s nasty stuff.

Taking 20 minutes to prep saves you from cursing later. Trust me, I’ve been there.

How Do I Disassemble an Evinrude Carburetor Safely?

Disassembly is where things get real. Rush this, and you’re screwed on reassembly. Last June, a client’s Evinrude 200 at Stiltsville wouldn’t start—turned out his shop skipped proper cleaning. Here’s my process:

- Document Everything: Snap photos of every angle before touching anything. Capture throttle linkages, fuel lines, and springs. I use my phone—it’s my reassembly cheat sheet.

- Remove the Carb: Unclip linkages, detach fuel and primer lines, and remove the air silencer if needed. Unbolt the two mounting nuts (1/2″ or 9/16″) and pull the carb free.

- Take It Apart: On a clean bench, remove the fuel bowl, float, needle, and jets. Use a perfectly-fitting flathead for the brass main jet—test the fit to avoid stripping.

Keep parts organized in your tray. One lost screw can stall your project.

How Do I Clean an Evinrude Carburetor Properly?

Cleaning’s the heart of the job. A visually clean carb isn’t enough—clogged passages kill performance. In 2023, I fixed a client’s Evinrude 90 at Bahia Mar that another shop “cleaned.” Their mistake? Skipping compressed air. Here’s how I do it:

- Soak Metal Parts: Submerge the carb body, bowl, and jets in CRC carb cleaner for 15 minutes.

- Clear Jets: Use a soft wire (12-gauge strand) to gently unclog jets. Never force it—you’ll ruin the jet.

- Blow It Out: Use compressed air (80–100 PSI) through every passage. I check by holding jets to the light—clear ones shine. This step caught a $500 issue for a guy’s boat last month.

A spotless carb means smooth fuel flow. Skimp here, and you’re back to square one.

How Do I Set the Float Height on an Evinrude Carburetor?

The float height is make-or-break. Too high, your engine floods; too low, it starves. Last spring, a client’s Evinrude 115 at Dinner Key ran lean because the float was off by 2mm—cost him $300 in diagnostics. Here’s my method:

- Install New Float and Needle: Slide the new needle into its seat and attach the float with the hinge pin (from your Sierra kit).

- Measure Carefully: Flip the carb upside down so the float rests on the needle. Measure from the gasket surface to the float’s top, per your service manual. A good rule: the float seam should be parallel to the carb body.

- Adjust Precisely: Bend the float’s metal tab gently to hit the spec. I use needle-nose pliers and re-measure after each tweak—takes 5 minutes but saves headaches.

Get this right, and you’ve nailed 80% of the rebuild’s success.

How Do I Reassemble an Evinrude Carburetor Correctly?

Reassembly is where precision pays off. I botched a job in 2010 by rushing—leaky gaskets cost me a weekend. Here’s how I do it now:

- Match Parts: Lay out your Sierra kit’s parts next to the old ones. Extra parts are normal; kits cover multiple models.

- Install Gaskets and Jets: Fit new gaskets and O-rings (surfaces must be clean and dry). Screw in cleaned jets to their original spots—hand-tight, no gorilla force.

- Attach Fuel Bowl: Align the bowl with the new gasket and tighten screws in a crisscross pattern. Snug, not cranked—over-torquing warps the bowl.

Double-check your photos to ensure everything’s back where it belongs.

How Do I Tune an Evinrude Carburetor for Peak Performance?

Tuning’s what makes your engine sing. I tuned a client’s Evinrude 150 at Key Biscayne last summer—smooth idle, no hesitation, all from a 10-minute tweak. Here’s the process:

- Mount the Carb: Place a new mounting gasket on the engine block to prevent vacuum leaks. Tighten nuts evenly in a crisscross pattern—snug, not crazy tight.

- Set Idle Screw: Turn the low-speed mixture screw clockwise until it seats lightly, then back out 1.5 turns. This works for most Evinrudes.

- Check for Leaks: Prime the fuel bulb and inspect connections. I caught a $200 leak this way on a client’s boat in July 2024.

- First Start: Run the engine on muffs or in the water. Let it warm up for 5 minutes.

How Do I Fine-Tune an Evinrude Carburetor on the Water?

Shop tuning’s not enough—real-world conditions matter. I learned this in 2015 when a client’s Evinrude 200 hesitated under load. Here’s my on-water routine:

- Warm Up: Run the engine in gear with a slight load (e.g., cruising at 5 knots).

- Adjust Idle Mixture: Turn the idle screw in (clockwise) in 1/8-turn steps until the engine sputters, then out until it stumbles. Find the sweet spot in the middle.

- Set Idle Speed: Adjust the idle speed screw to hit the manual’s RPM (usually 600–800). I use a tachometer—$50 well spent.

This ensures smooth acceleration and a steady idle. My client’s boat purred like new after this.

FAQ: Common Evinrude Carburetor Rebuild Questions

Why Does My Evinrude Carburetor Keep Clogging?

Ethanol fuel and saltwater are brutal—70% of clogs I see come from water in the fuel. I add a $10 fuel treatment every fill-up and check filters monthly. Last June, this saved a client’s Evinrude 90 from a $500 overhaul. Use a phase separation test kit to catch issues early.

How Often Should I Rebuild My Evinrude Carburetor?

Every 3–5 years or 500 hours, depending on use. I rebuilt a client’s Evinrude 115 at Bahia Mar in 2024 after 4 years—cost $150 vs. $800 at a shop. Check your service manual and inspect jets yearly. Try Sierra kits for reliable parts.

Can I Use a Generic Carburetor Rebuild Kit?

No way—generic kits leak or fit poorly. I tried one in 2011; it cost me $200 to fix. Use your engine’s model and serial number to get a Sierra kit. It’s $30–$50 and ensures a perfect seal.

What’s the Best Carburetor Cleaner for Evinrude?

I swear by CRC Carb Cleaner—cuts gunk fast. Spray it, soak for 15 minutes, then blast with compressed air. I fixed a client’s Evinrude 200 last month with this—saved $300. Get it at West Marine for $10.

How Do I Know If My Float Height Is Wrong?

Flooding or lean running means it’s off. I measure with a caliper to hit the manual’s spec—usually parallel to the carb body. A bad setting cost a guy at Dinner Key $400 in 2023. Double-check with your service manual.

Why Is My Engine Still Rough After a Rebuild?

Check your tuning—90% of post-rebuild issues are bad idle settings. I fixed a client’s Evinrude 150 last July by tweaking the idle screw on the water. Start at 1.5 turns out and adjust in gear. A tachometer helps.

Can I Rebuild My Carburetor Myself?

If you’ve got basic tools and patience, yes. I showed a buddy at Key Biscayne how to rebuild his Evinrude 90 in 2 hours—cost $40 in parts. Stick to my steps, take photos, and don’t rush. For complex issues, call a pro with ABYC certs.

What Are the Key Takeaways for a Successful Rebuild?

Here’s what I’ve learned from 200 rebuilds:

- Prep Saves Pain: A clean bench, Sierra kit, and perfect screwdriver prevent disasters.

- Clean Deep: Compressed air through every passage is non-negotiable—visual shine isn’t enough.

- Float Right: Set the float seam parallel to the carb body to avoid flooding or starving.

- Tune on Water: Adjust the idle screw under load for real-world performance.

Conclusion: Your Engine’s New Life Starts Now

Rebuilding your Evinrude carburetor isn’t just a repair—it’s a skill that saves you hundreds and keeps your boat running like a dream. I’ve seen guys at Dinner Key go from frustrated to stoked after nailing this job. Follow my steps, and you’ll hear that engine purr without hesitation.

Grab your model number, order a Sierra kit, and get that CRC cleaner today. The satisfaction of a smooth idle and full power is worth every minute. You’ve got this—hit the water with confidence.

Author Bio

I’m Alex, a 15-year marine mechanic with ABYC certification, based in Fort Lauderdale. I’ve rebuilt 200+ outboards, mostly Evinrudes and Mercurys, across Miami’s marinas. My work’s saved clients thousands in shop fees. Follow me on LinkedIn: linkedin.com/in/alex-marine-tech.

Leave a Reply